Corrosion device and method for preparing two-color film layer on metal surface

A metal surface and corrosion device technology, which is applied in the field of metal surface treatment, can solve the problems of difficult appearance processing of internal and external structures, high requirements for etching process control, uniform two-color film layers, etc., to achieve good connection effect, clear dividing line, and realization The effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further specifically described below in conjunction with the accompanying drawings and embodiments.

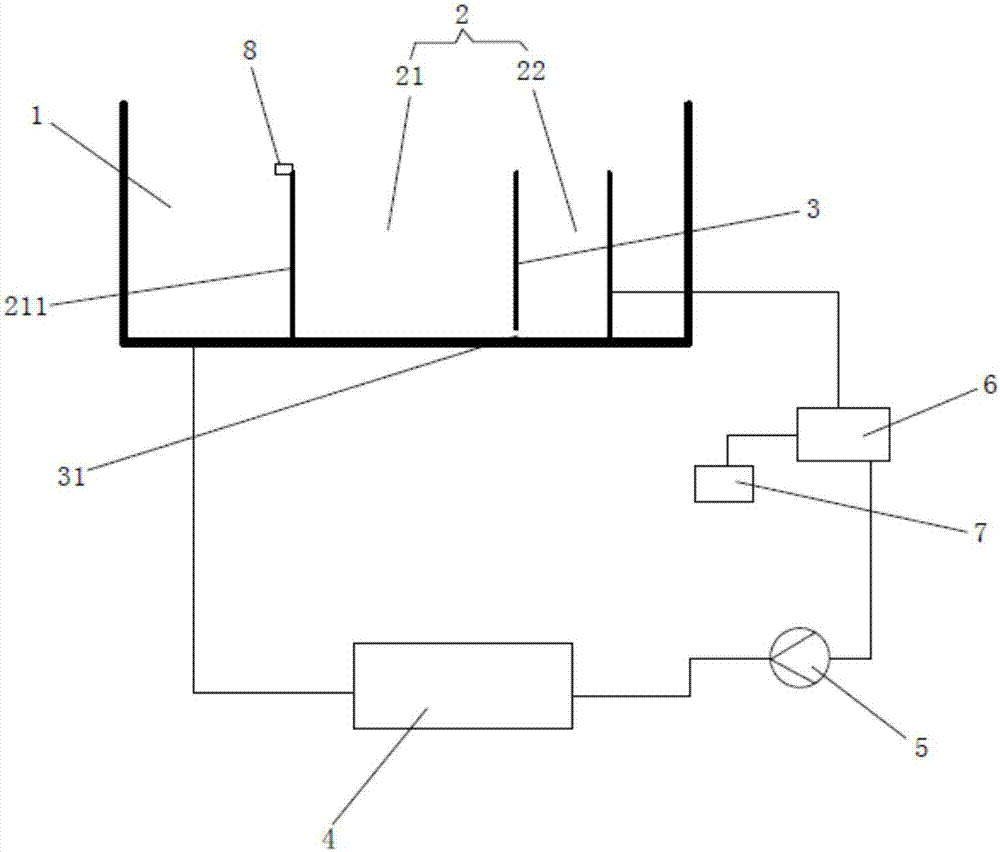

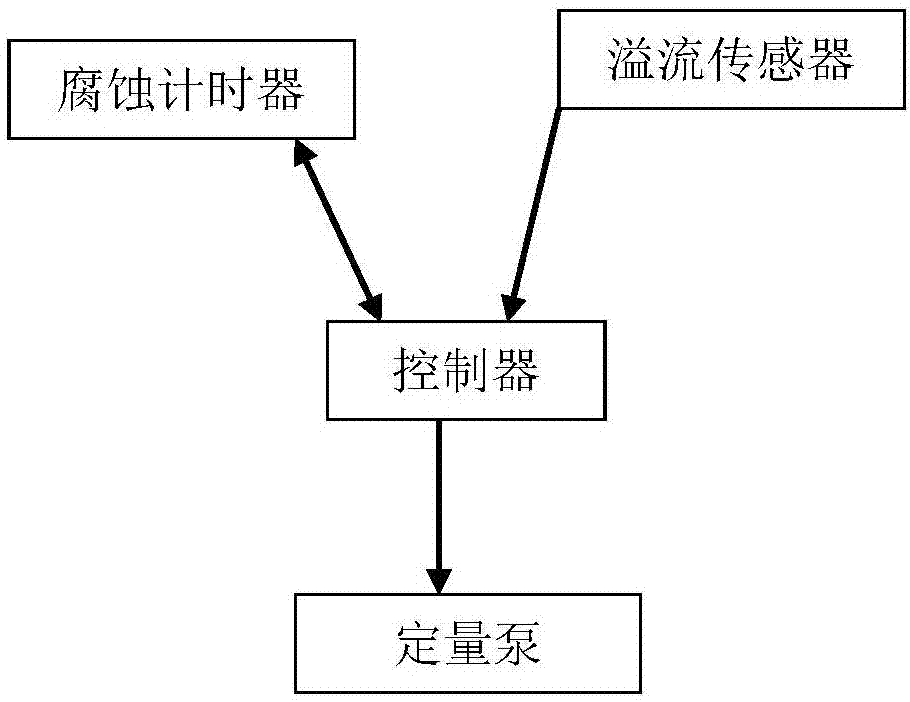

[0026] refer to figure 1 with figure 2 An etching device for preparing a two-color film layer on a metal surface includes a tank mechanism, a pipetting mechanism and a control mechanism. The tank mechanism includes an outer tank body 1 and a communication tank 2, the communication tank 2 is arranged in the outer tank body 1, and the communication tank 2 includes a first tank body 21 and a second tank body 22 whose bottoms communicate with each other, wherein the first tank body The body 21 is used to accommodate the part of the metal article to be corroded. The pipetting mechanism includes a liquid storage tank 4 and a quantitative pump 5, and the quantitative pump 5 is connected to the liquid storage tank 4 and the second tank body 22; the control mechanism includes a controller 6, a corrosion timer 7 and an overflow sensor 8, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com