Air jet flow dedusting device for drilling of mine

A dust collector and jet technology, used in mining equipment, earth-moving drilling, gas discharge, etc., can solve the problem of easy sliding of the inflatable anti-blown dust collector, reduce blockage of the air inlet, improve airflow resistance, increase and improve The effect of the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

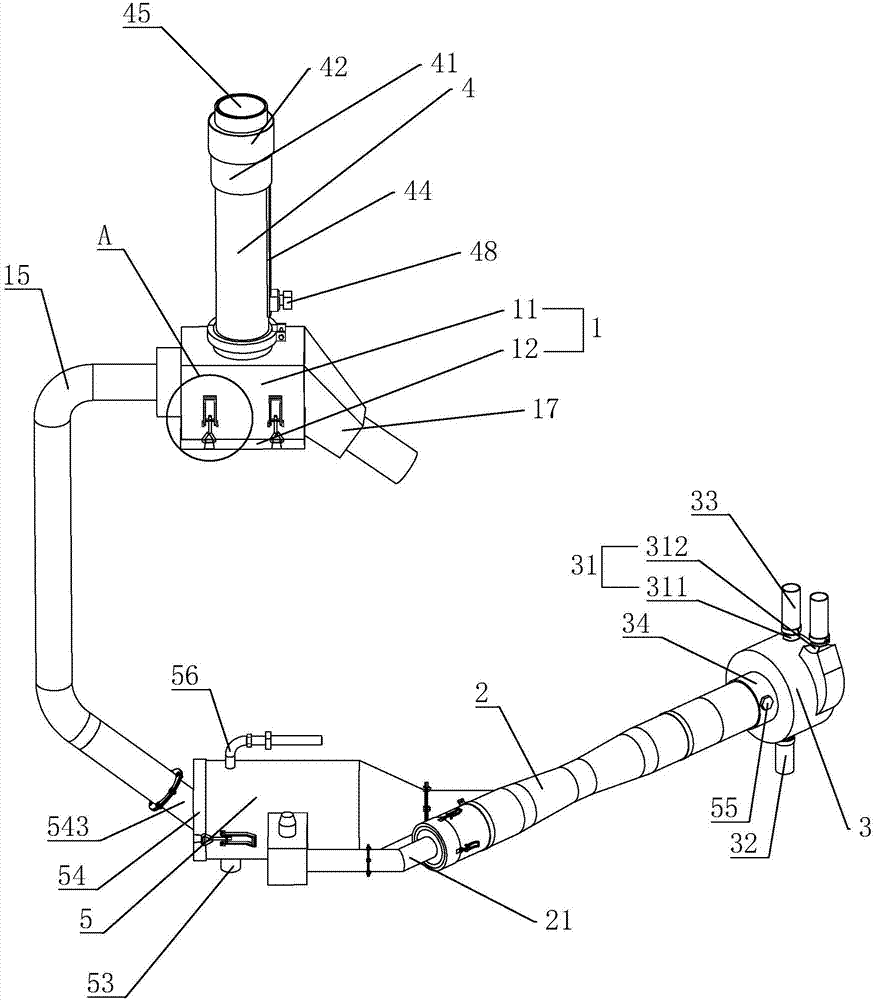

[0044] Embodiment 1: a kind of air jet dust collector for mine drilling, such as figure 1 As shown, it includes in turn the expansion type anti-spray dust collection pipe 4, the composite dust collection cover 1 with anti-spray holes, the dust delivery pipe 15, the atomization dust removal chamber 5, the jet pipe 2 and the gas collector 3, all of which are welded by stainless steel plates , has good corrosion resistance, and the equipment has the advantages of light weight, high strength, not easy to damage, and long service life.

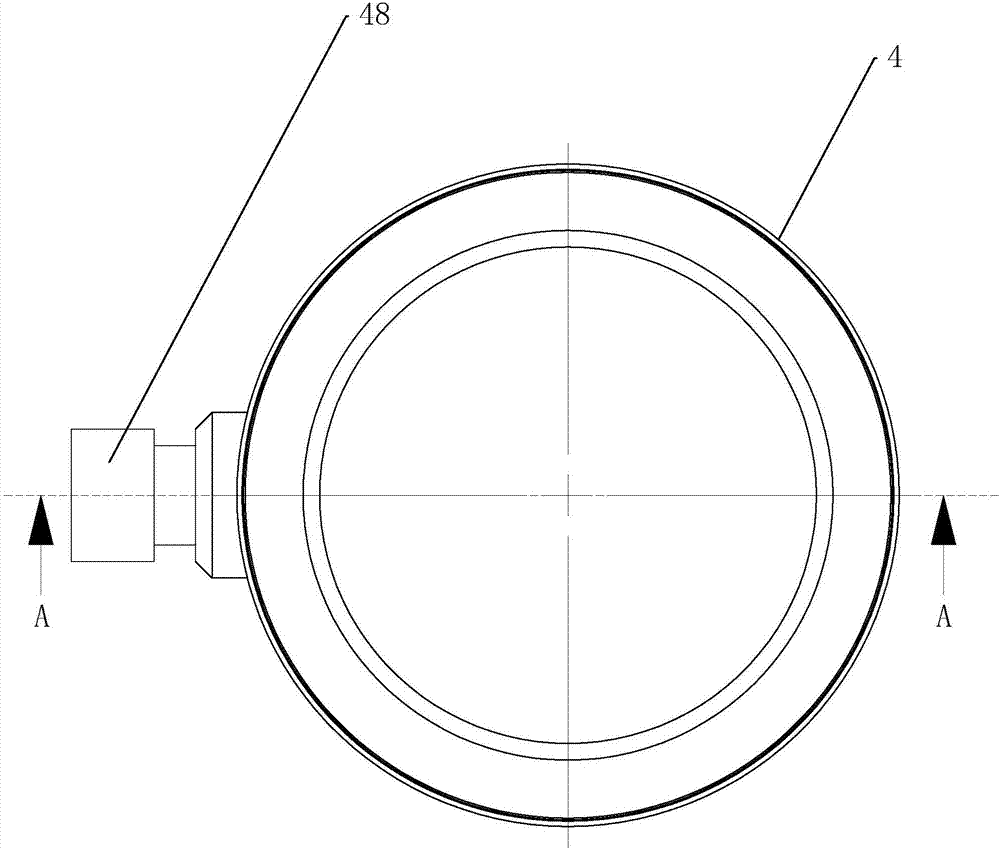

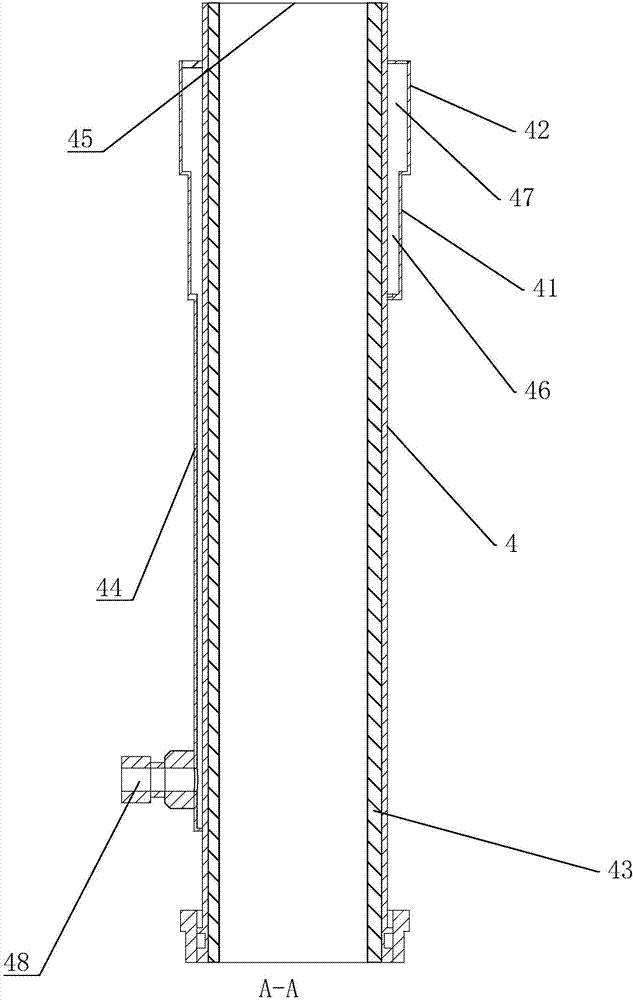

[0045] Such as figure 1 and 3 As shown, the end of the expansion type anti-spray dust collection pipe 4 extending into the borehole is a gas inlet 45, and the end of the expansion type anti-spray dust collection pipe 4 near the gas inlet 45 is sleeved with a stainless steel pipe 41, the stainless steel pipe 41 is sealed and welded on the outer pipe wall of the expansion type spray-proof dust collecting pipe 4 at one end away from the gas inlet 45...

specific Embodiment approach

[0057] Specific implementation method: when the operator uses it, first use a drilling machine to initially drill holes, then take out the drill pipe, place the expansion type anti-spray dust collection pipe 4 in the drill hole, and then place the expansion type anti-spray dust collection pipe 4 4 The end close to the water pipe 44 is connected to the drill pipe outlet 13 of the blowout hole composite dust collection cover 1, and the air inlet pipe 2 543 of the atomizing dust removal pipe is connected to the blowout hole composite dust collection cover 1 through the dust delivery pipe 15 , and then through the threaded rod 55 or snap piece 16 and hook 165, the atomizing dedusting chamber 5, the jet pipe 2 and the gas collector 3 are quickly connected in sequence, and the jet pipe 2 is connected to the gas collector 3 through the snap piece 16 and the hook 165. The high-pressure gas delivery pipe 21 is connected, and the air jet dust collector for this kind of mine drilling can ...

Embodiment 2

[0061] Embodiment 2: a kind of air jet dust collector for mine drilling, such as Figure 12 As shown, the difference from Example 1 is that the opening direction of the coal dust discharge pipe 17 is perpendicular to the blowout hole composite dust collection cover 1, and this kind of blowout hole composite dust collection can be used except for drilling at a large elevation angle. When the cover 1 is used for drilling in a nearly horizontal direction, the coal dust discharge pipe 17 is made vertically downward or obliquely downward by rotating the anti-spout hole composite dust suction cover 1, which is convenient for large particles of coal dust to be naturally discharged under the action of gravity. Slip, and can not accumulate in coal dust discharge pipe 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com