A modified structure for press mounting and positioning of semiconductor element and heat pipe radiator base plate

A technology of heat pipe radiator and positioning structure, which is applied to semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve the problem of large contact thermal resistance, and achieve the reduction of substrate size, contact thermal resistance, and size reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

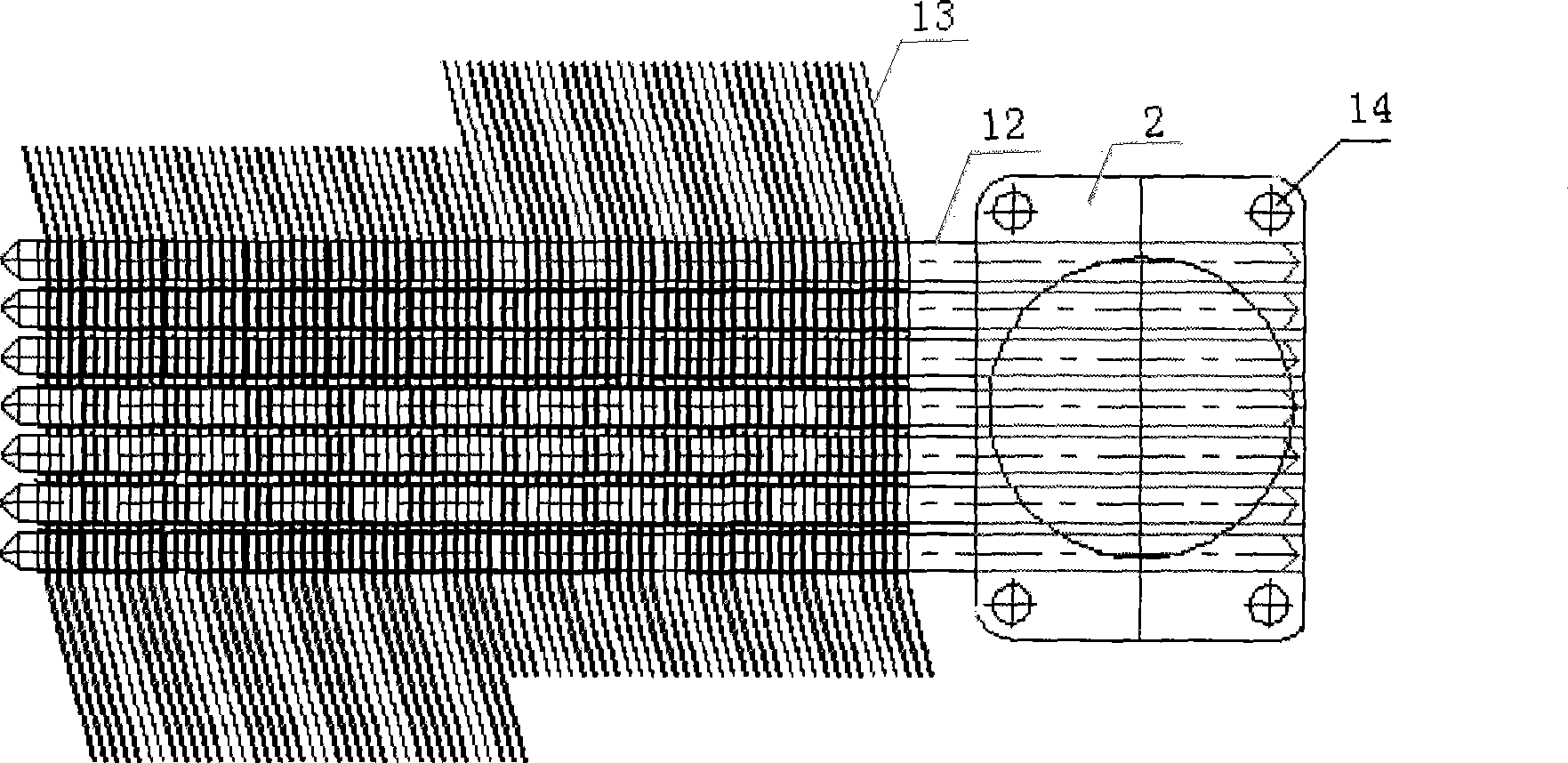

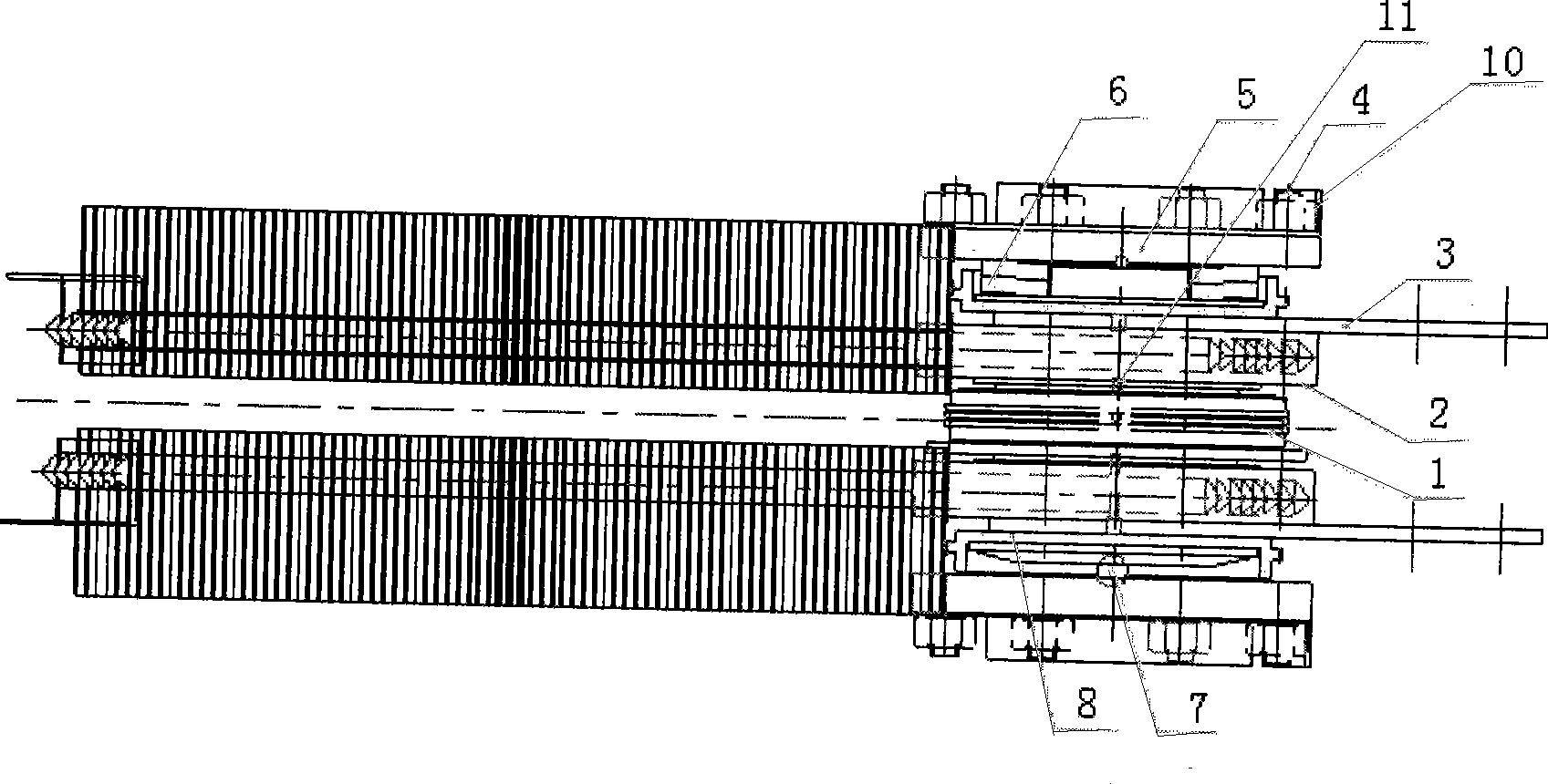

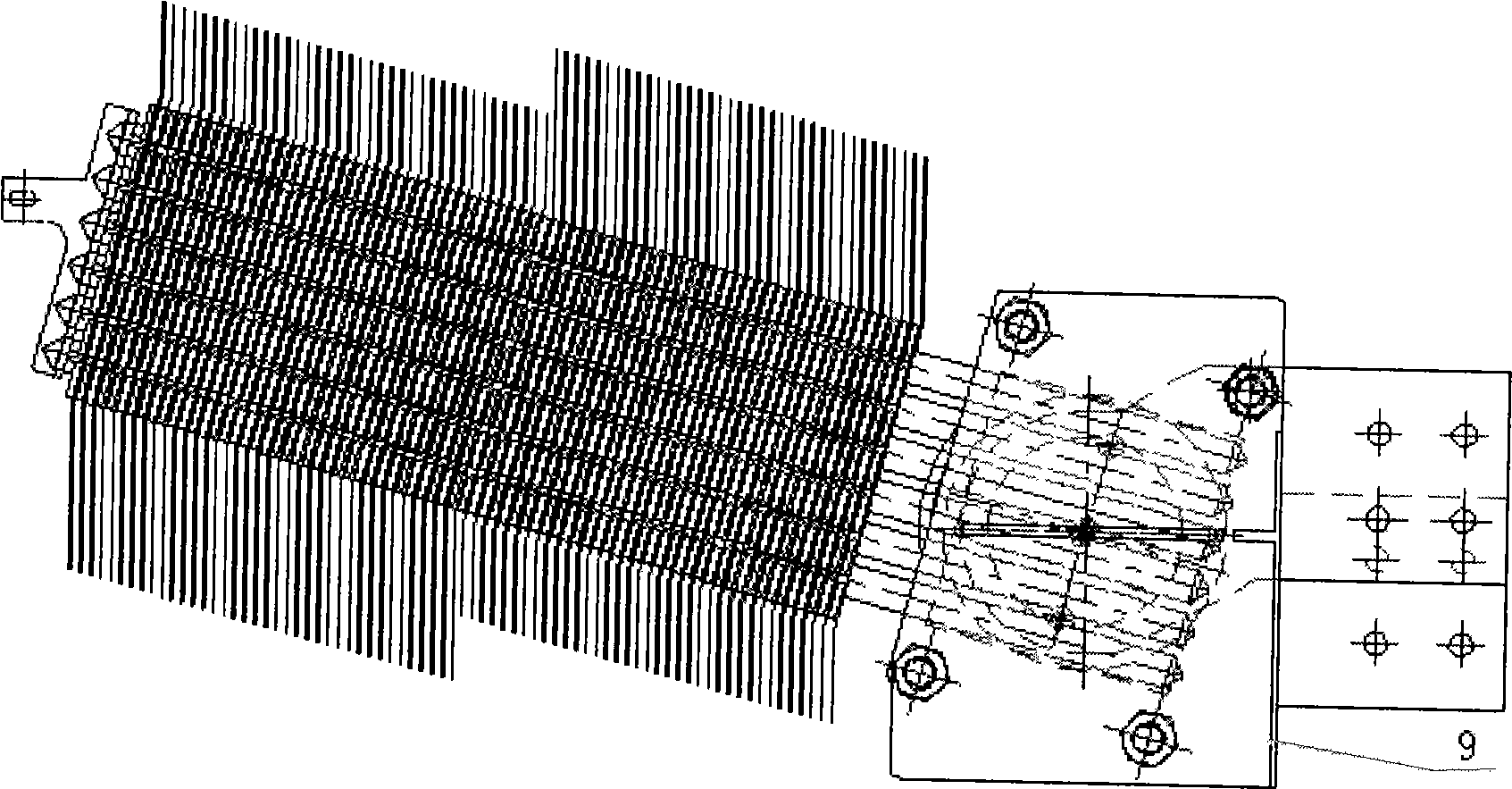

[0016] figure 2 , image 3 A schematic diagram of the structure of an embodiment of the present invention is given, which can be applied to rectification devices of domestic Shaoshan series electric locomotives and diesel locomotives.

[0017] The press-fit positioning structure mainly consists of the heat pipe radiator substrate 2, the 3-5 inch silicon rectifier element 1 located between the substrates 2, the external conductive connecting plate 3 fixed on the substrate 2, and the fastening mechanism for fastening the substrate 2 and the semiconductor element 1. The elastic press-fit assembly consists of a fastening screw 4, a fastening nut 10, a spring plate 5, a disc spring 6, a steel ball 7, an insulator 8, and a positioning pin 11. The elastic press-fit assembly is arranged on the rectifier The supporting part 9 on the top is fixed and positioned, and the heat pipe radiator base plate 2 is located in the area formed between the elastically pressed fastening screws 4. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com