Real-time liquid level tracking control method for hydraulic station of hot continuous rolling temper unit

A technology of tracking control and hydraulic station, applied in metal rolling, metal rolling, mechanical equipment, etc., can solve problems such as unreasonable alarm settings, failure to monitor oil spills in time, energy waste, etc., and achieve good market promotion value and Reasonable foreground and alarm settings and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

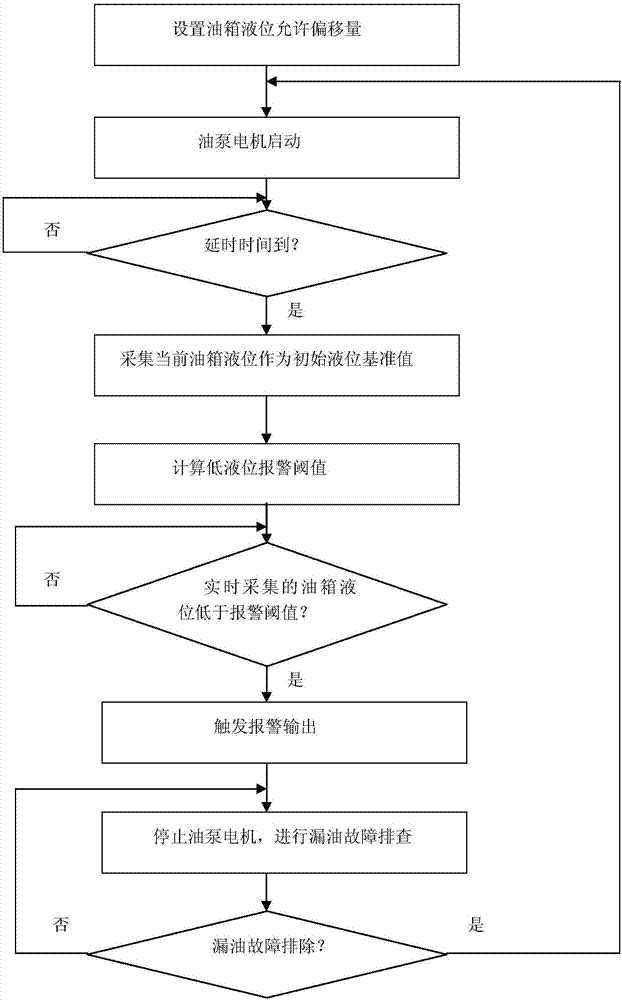

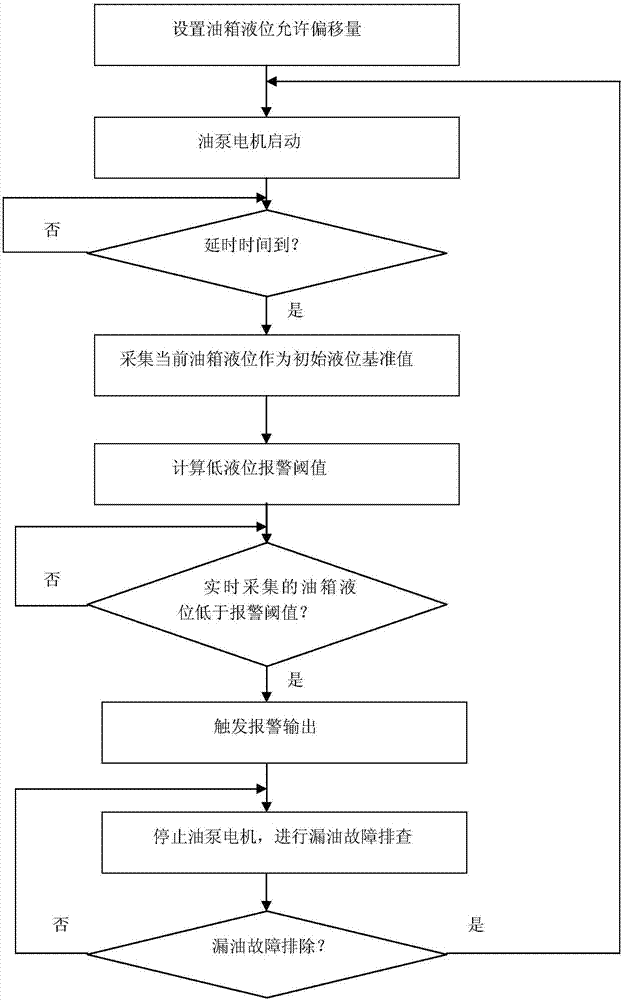

[0026] The present invention aims to propose a real-time liquid level tracking control method for the hydraulic station of the tempering unit in the hot continuous rolling, so as to solve the unreasonable alarm setting in the liquid level control scheme of the hydraulic station of the tempering unit in the traditional technology, and the failure to monitor the oil leakage event in time, which is easy to cause energy loss. waste problem.

[0027] The core idea of the present invention is: by setting the allowable deviation of the liquid level of the hydraulic station as the allowable oil leakage, use the storage function of the hydraulic system PLC to record the initial liquid level value after the hydraulic system oil pump is started for one minute, and use the initial liquid level The low liquid level alarm threshold of the hydraulic system alarm is obtained by subtracting the allowable oil leakage from the numerical value; during the operation of the system, the liquid leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com