Heat-shielding structure of steering engine

A steering gear and heat protection technology, which is applied in the direction of projectiles, offensive equipment, weapon types, etc., can solve the problems of large space occupied by the heat insulation layer, unsatisfactory heat protection effect, high coating spraying temperature, etc., to achieve effective heat isolation, Small footprint and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

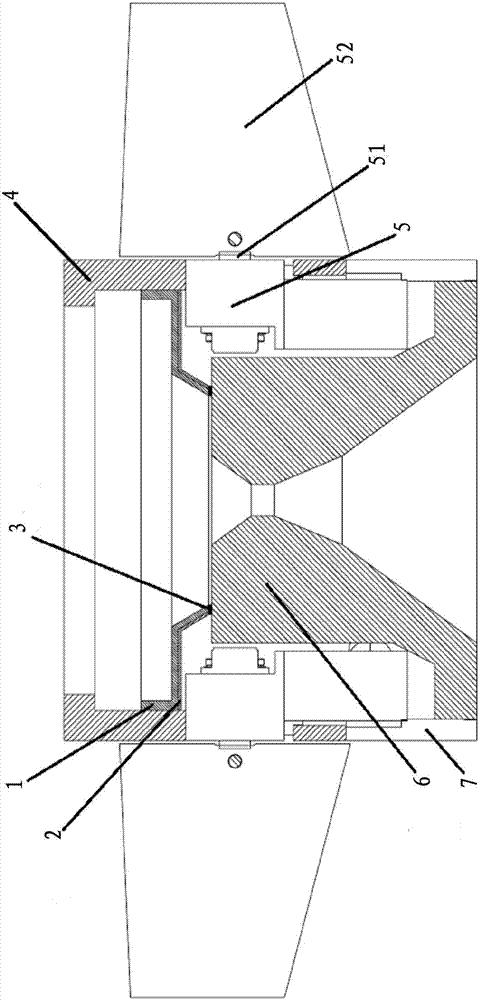

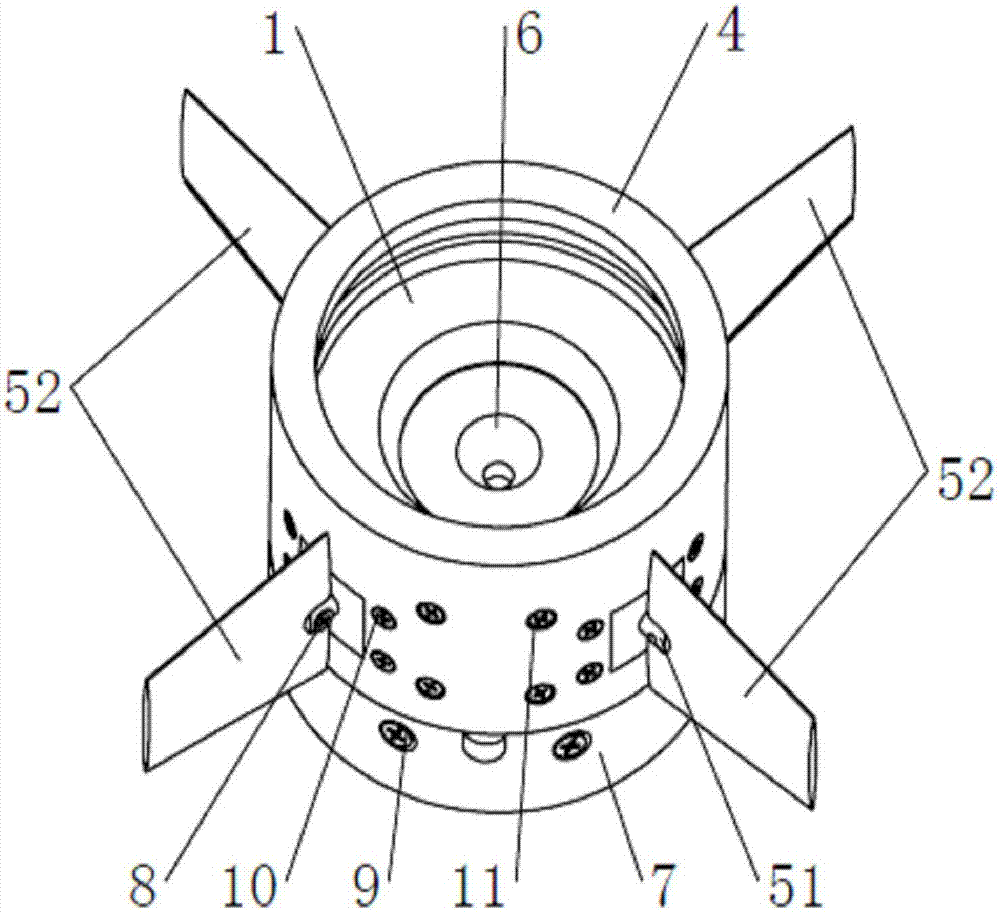

[0039] figure 1 A longitudinal sectional view of an embodiment of a target missile installed with a steering gear heat-proof structure of the present invention is shown, figure 2 is a full perspective view of the embodiment. The target projectile has structural elements of the body shell 4, steering gear 5, rudder shaft 51, steering surface 52, tail nozzle 6 and engine casing 7, and the steering gear 5 is fixed on the body shell 4, tail nozzle In the sealed cavity surrounded by the tube 6, the engine casing 7, and the heat-proof structure of the steering gear. The inner surface of the rear section of the engine housing 7 and the outer surface of the front section of the tail nozzle 6 are connected by large threads, the rear section of the engine housing 7 and the front section of the body casing 4 are connected by screws 29 distributed along the radial direction, and the body casing 4 It is connected with the steering gear 5 through three screws 10 distributed radially, and...

Embodiment 2

[0042] Embodiment 2. Simulation analysis of heat insulation effect

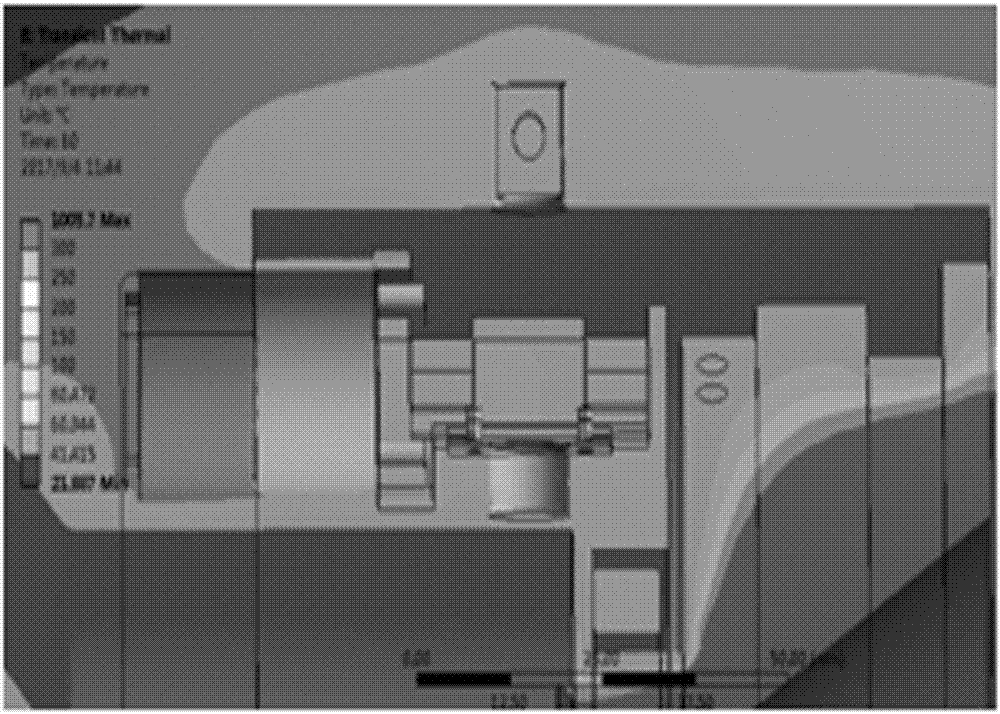

[0043] Use Ansys to simulate the heat insulation effect of the steering gear shield. The thickness of the steel plate in the simulation model is 2mm. The outer surface temperature caused by aerodynamic heating is set to 85°C, the engine tail flame temperature is 1000°C, and the tail nozzle outer surface temperature is 90°C. The temperature transfer of the surrounding environment of the steering gear with and without the steering gear shield is studied. The simulation results are shown in image 3 and Figure 4 . The irregular curves in the figure are the edges of different temperature ranges, and the darker the color, the higher the temperature. It can be seen from the figure that the tail nozzle flame heat is completely isolated outside the protective cover (see image 3 The dark area on the right), which reduces the risk of the tailpipe flame heat affecting the normal operation of the servo.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com