Tile detection apparatus and detection method based on RGB-D camera

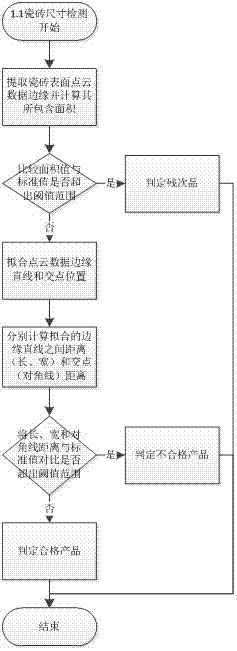

The technology of a detection device and detection method is applied in the direction of measuring devices, optical devices, and optical testing of defects/defects, which can solve problems such as low efficiency, inability to detect dimensions, defects and flatness, and single detection functions, and achieve stable work. Reliable, fast and high-precision detection, the effect of high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

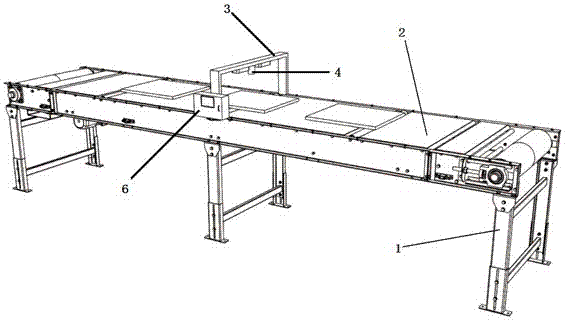

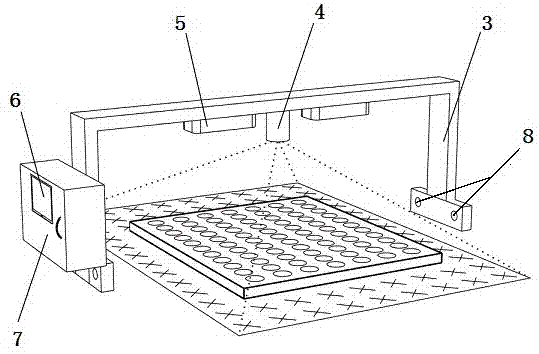

[0029] Such as figure 1 , 2 Shown, the present invention a kind of ceramic tile detection device based on RGB-D camera, comprises frame 1, conveyor belt conveying mechanism 2, support 3, RGB-D camera 4, light source 5, microcomputer and liquid crystal display 6. The conveyor belt conveying mechanism 2 is installed on the frame 1; the bracket 3 is a door-shaped structure and installed across the conveyor belt conveying mechanism 2; the RGB-D camera and light source are fixed on the housing bracket, and the The conveyor belt conveying mechanism, the RGB-D camera, and the light source are all controlled by a microcomputer, and the liquid crystal display screen is connected with the microcomputer. There is also a cabinet 7 on one side of the support 3, the cabinet is provided with an openable cabinet door, the microcomputer is installed inside the cabinet, the liquid crystal display 6 is installed on the cabinet door, and the photoelectric sensor 8 is installed on the cabinet Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com