Method used for detecting assimilation temperature based on iron ore powder temperature-electric signal curve

An electrical signal, iron ore powder technology, applied in the field of iron ore powder sintering characteristic detection, can solve problems such as large influence of subjective factors and inaccurate detection results, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

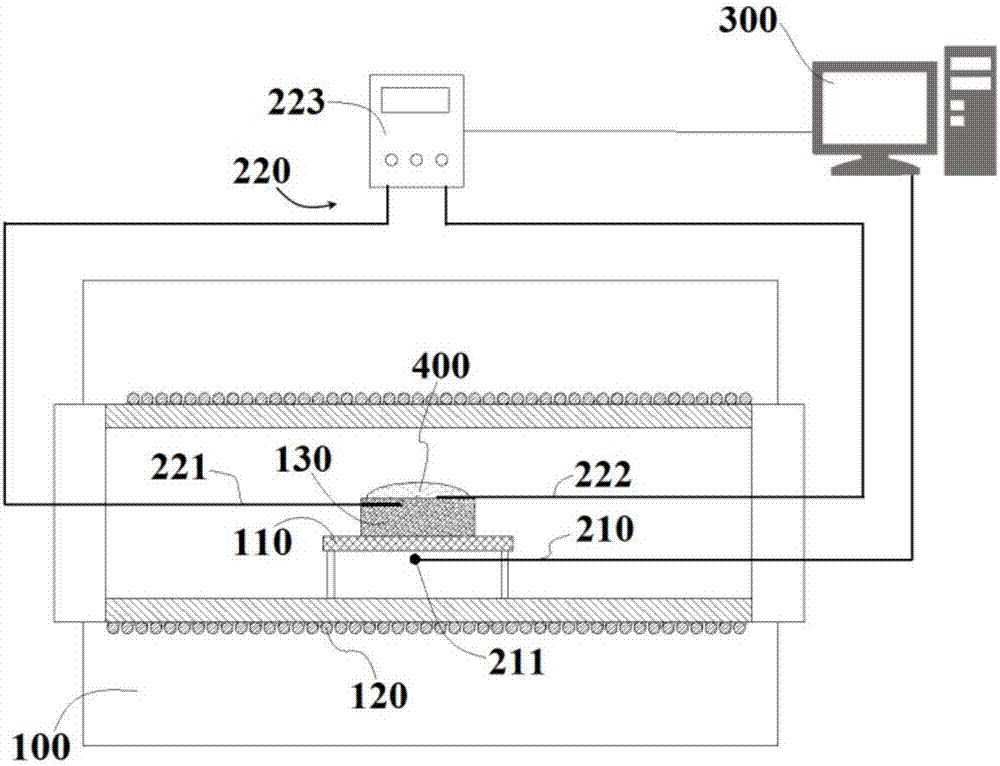

[0045] A method of detecting the assimilation temperature based on the iron ore powder temperature-electrical signal curve in this embodiment detects the electrical signal and temperature changes of the iron ore powder sample 400 during the heating process, and determines the relationship between the electrical signal and the temperature. And draw the temperature-electric signal curve of iron ore powder sample 400, find the corresponding temperature value according to the sudden change of the electric signal of the curve, and detect the assimilation temperature of iron ore powder, especially creatively propose the use of temperature-electric signal curve to judge the iron ore The assimilation temperature of the mineral powder sample 400 greatly improves the detection efficiency and detection accuracy. Specific steps are as follows:

[0046] Step 1. Equipment assembly

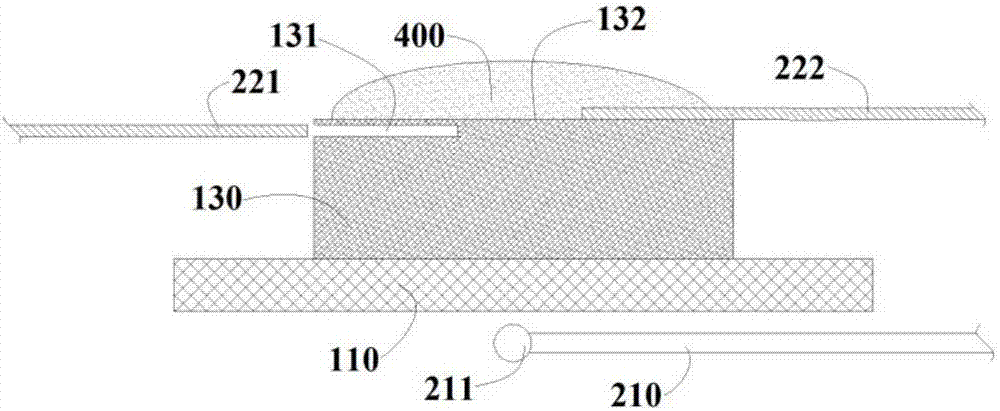

[0047] A. Weigh 2g of CaO powder with a purity of 98.0% with a balance, and press it into a convex mold unde...

Embodiment 2

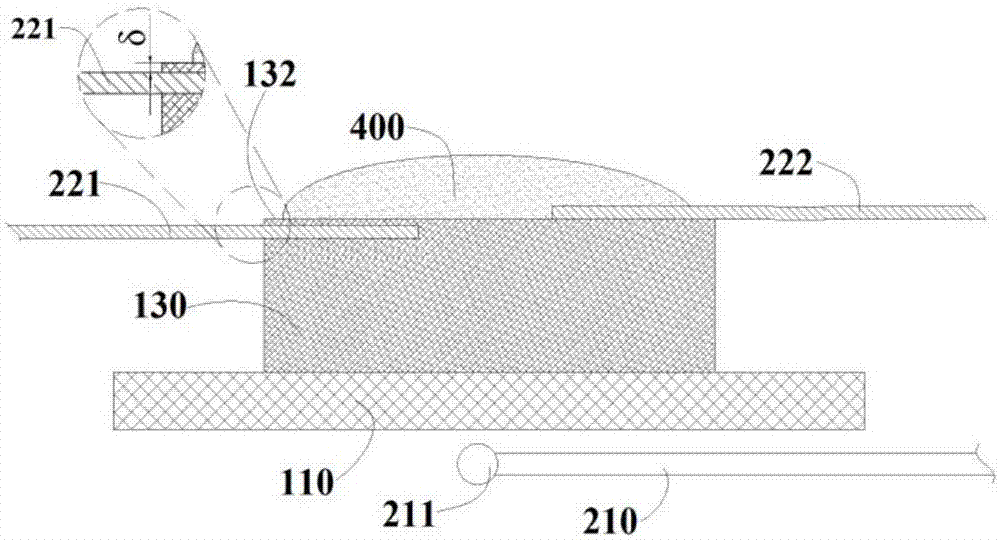

[0080] like Figure 4 As shown, the basic content of this embodiment is the same as that of Embodiment 1, except that the first electrode 221 and the second electrode 222 are arranged in parallel, and the horizontal distance between the first electrode 221 and the second electrode 222 is d, where d≤ R / 2, the present embodiment takes d=R / 2, and R is the diameter of the accumulation surface of the iron ore powder sample 400 on the calcium oxide tablet 130 . The first electrode 221 and the second electrode 222 run through the calcium oxide tablet 130, thereby improving the accuracy of detection, so that as long as the iron ore powder is assimilated in one place, the change of the electrical signal can be detected in time, thereby improving the detection accuracy. accuracy. In this embodiment, the thickness between the top of the electrode hole 131 and the upper surface of the calcium oxide sheet 130 is δ, and δ is 0.2-2mm. In this embodiment, δ=0.5mm.

Embodiment 3

[0082] like Figure 7 As shown, the basic content of this embodiment is the same as that of Embodiment 1, except that the first electrode 221 of this embodiment is placed in the calcium oxide pellet 130 , and the second electrode 222 is placed in the iron ore powder sample 400 . The detection unit 200 is located on the upper part of the iron ore powder sample 400, and the detection unit 200 is located directly above the first electrode 221, and the temperature measurement end 211 of the detection unit 200 is close to the iron ore powder sample 400, so that the temperature measurement end 211 can promptly and quickly detect the temperature when the assimilation reaction of iron ore powder occurs, and improve the accuracy of detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com