Process suitable for rapidly screening corrosion inhibitor of carbon dioxide flooding oil production well

A technology of carbon dioxide and corrosion inhibitors, which is applied in the direction of material analysis by observing the influence of chemical indicators, electrochemical variables of materials, and weighing by removing certain components, so as to achieve excellent protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

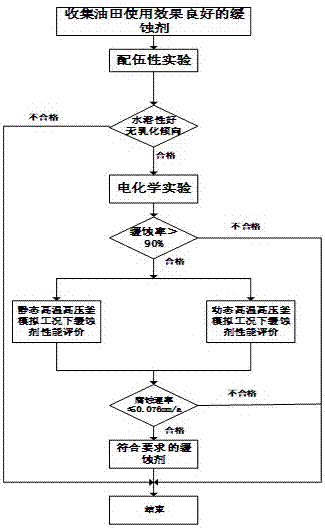

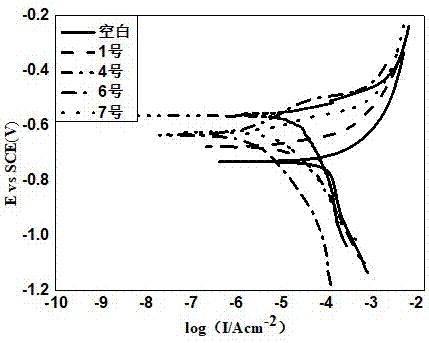

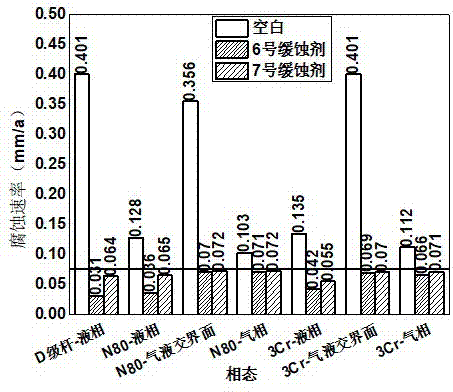

[0039] The present invention is completed by following process operation: (1) collect the corrosion condition parameter of oil production well; (2) collect the corrosion inhibitor kind that meets corrosion condition, and its serial number; (3) correlate to the corrosion inhibitor collected Capacitance test to screen out corrosion inhibitors with good compatibility with on-site water; (4) use electrochemical corrosion detection methods to further screen out corrosion inhibitors with a corrosion inhibition rate greater than 90%; (5) use static high-temperature autoclave experiments , the corrosion weight loss evaluation experiment was carried out on the corrosion inhibitors screened in the previous step, and the corrosion inhibitors with a corrosion rate ≤ 0.076mm / a were screened out; Evaluation experiments determine the corrosion inhibitors with a corrosion rate of ≤0.076mm / a and their serial numbers. The screening process provided by the present invention can efficiently and qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com