Power supply control device and control characteristic correction data generation method for power supply control device

A technology of power supply control and current detection resistance, which is used in computer control, transmission control, general control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0084] Detailed Description of Embodiment 1

[0085] (1) Detailed description of the structure

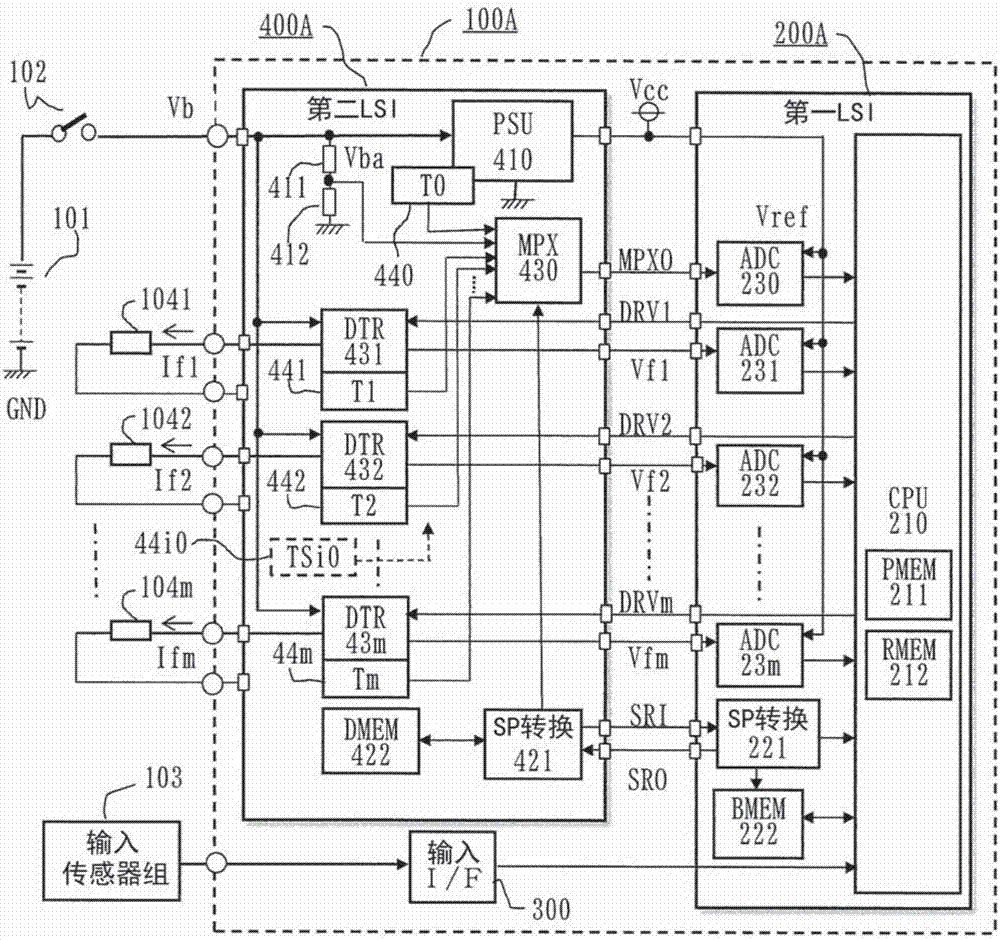

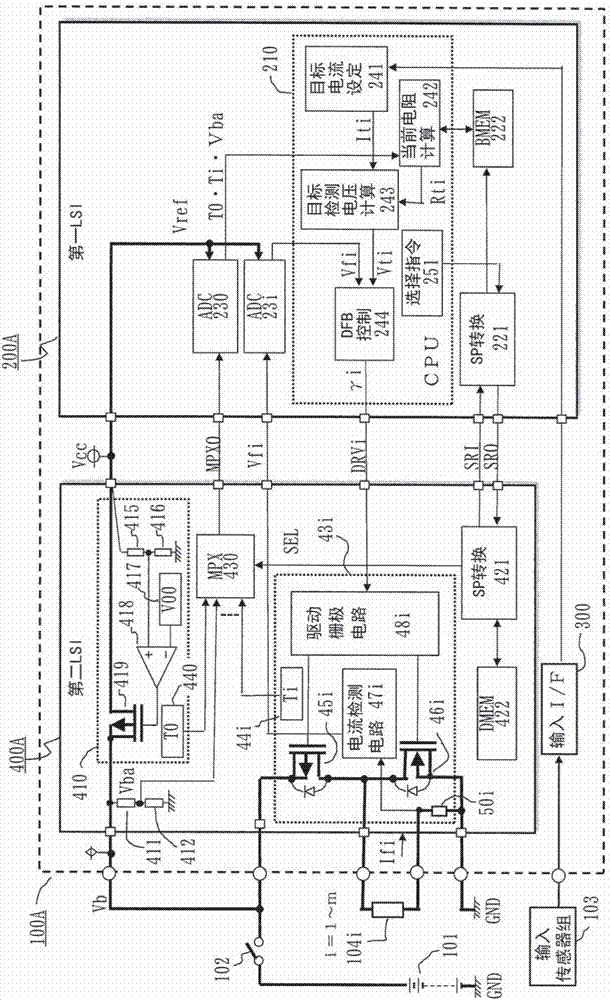

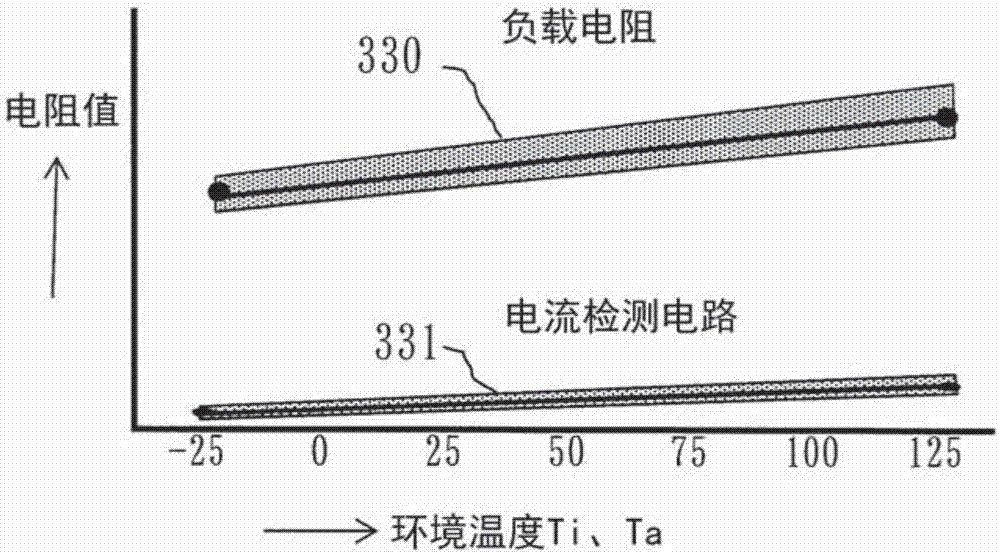

[0086] Next, the overall circuit block diagram of the power supply control device according to Embodiment 1 of the present invention is figure 1 , and involving figure 1 A detailed circuit block diagram of a power supply circuit part of the device is figure 2 , to describe its structure in detail.

[0087] first, figure 1 Among them, the power supply control device 100A, for example, supplies the inductive loads 104i (i=1, 2... The load current Ifi varies, and the power supply voltage Vb is applied from the DC power supply 101 as the vehicle battery via the output contact 102 of the power relay that is biased when the current switch not shown is closed.

[0088] The power supply control device 100A is composed of a first integrated circuit element 200A and a second integrated circuit element 400A, the first integrated circuit element 200A is mainly composed of a microprocesso...

Embodiment approach 2

[0278] Detailed Description of Embodiment 2

[0279] (1) Detailed description of the structure

[0280] Next, the overall circuit block diagram of the power supply control device according to Embodiment 2 of the present invention is Figure 7 , and involving Figure 7 A detailed circuit block diagram of a power supply circuit part of the device is Figure 8 , with figure 1 , figure 2 The structure will be described in detail centering on the different points of the device.

[0281] in addition, figure 1 , figure 2 The device of the first integrated circuit element 200A carries out the negative feedback control for the load current Ifi through the microprocessor 210 in the first integrated circuit element 200A, with respect to this, Figure 7 , Figure 8 The main difference of the device is that it is controlled by the negative feedback control circuit 49i provided in the second integrated circuit element 400B, and then the microprocessor 210 in the first integrated c...

Embodiment approach 3

[0367] Detailed Description of Embodiment 3

[0368] (1) Detailed description of the structure

[0369] Next, the overall circuit block diagram of the power supply control device according to Embodiment 3 of the present invention is Figure 11 , and design Figure 11 A detailed circuit block diagram of a power supply circuit part of the device is Figure 12 , with figure 1 , figure 2 The structure will be described in detail centering on the different points of the device.

[0370] in addition, figure 1 , figure 2 The device of the first integrated circuit element 200A carries out the negative feedback control for the load current Ifi through the microprocessor 210 in the first integrated circuit element 200A, with respect to this, Figure 11 , Figure 12 The device does not perform negative feedback control, and uses the load resistance Rci calculated by the current load resistance calculation unit 247 provided in the first integrated circuit element 200C, and uses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com