Automatic feeding air separation equipment

A technology of automatic feeding and air separation equipment, which is used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of inconvenient separation, dirty working environment, inconvenient cleaning, etc. The effect of reducing the difficulty of work, protecting physical health, and reducing cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are listed below, and detailed descriptions are as follows in conjunction with the accompanying drawings.

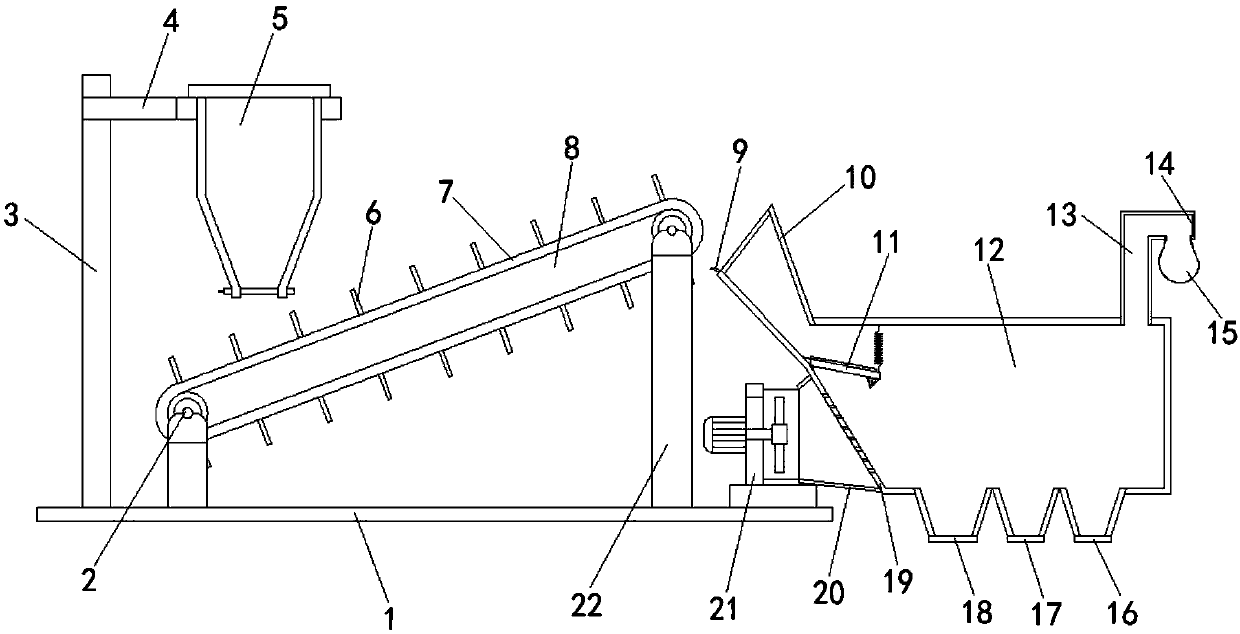

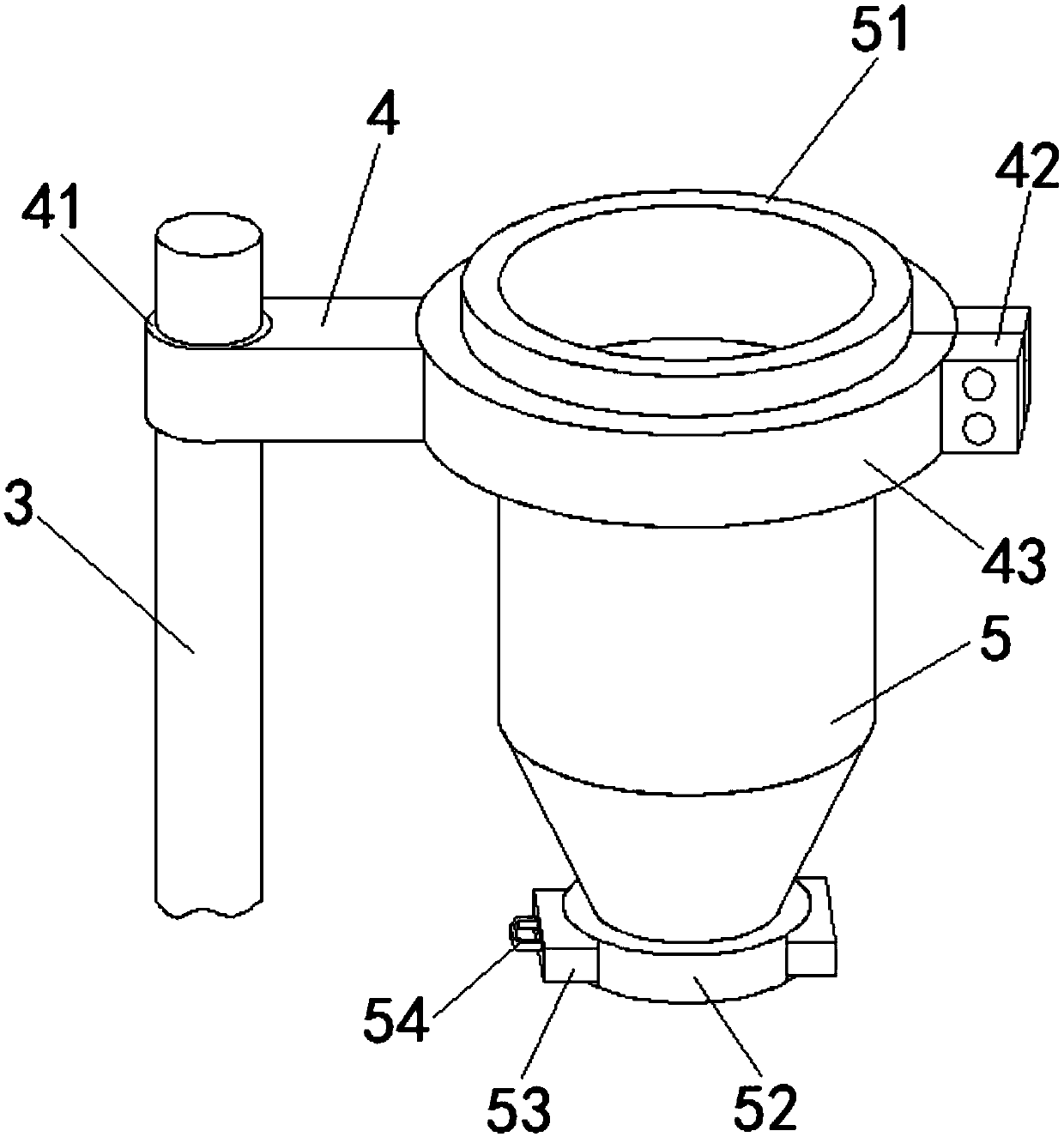

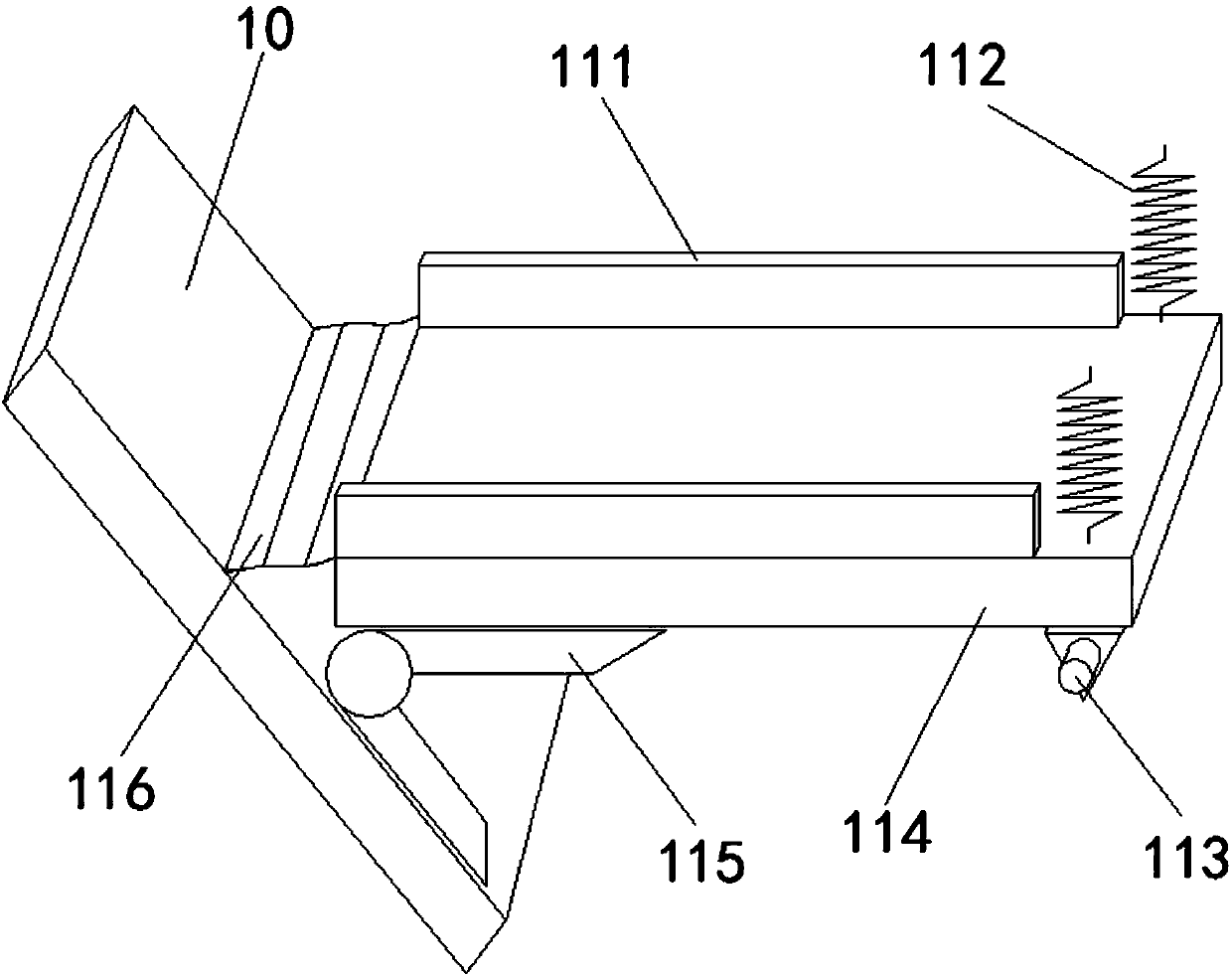

[0022] Combine below Figure 1-4 The structure of the automatic feeding winnowing equipment of the present invention is described in detail: an automatic feeding winnowing equipment, comprising a base 1, a raw material barrel 5, a conveyor belt 8, a feed hopper 10, a vibrating plate 11, a winnowing box 12, a dust Outlet 13, sundries outlet 16, good and miscellaneous mixed outlet 17, good product outlet 18 and fan device 21, above the base 1 are provided with barrel pole 3, conveyor belt bracket 22, fan device 21 and winnowing box in sequence from left to right 12. The upper end of the barrel support rod 3 is fixedly connected with a barrel support 4, one end of the barrel support 4 is fixed to the upper end of the barrel support rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com