Automatic machining device and machining system

A technology of automatic processing and angle adjustment device, which is applied in the direction of metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems that automatic operation cannot be realized, and achieve the effect of ensuring welding quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

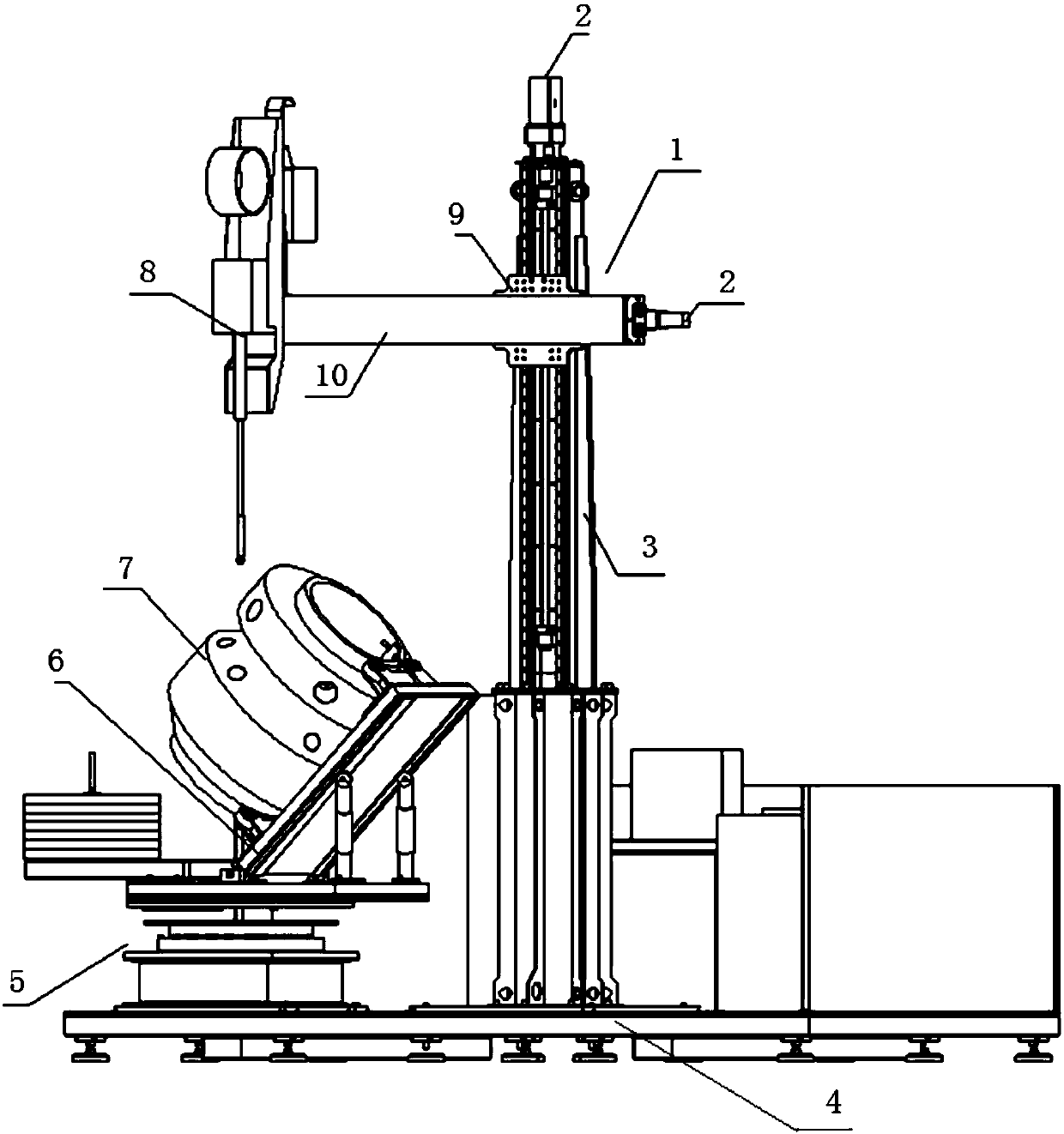

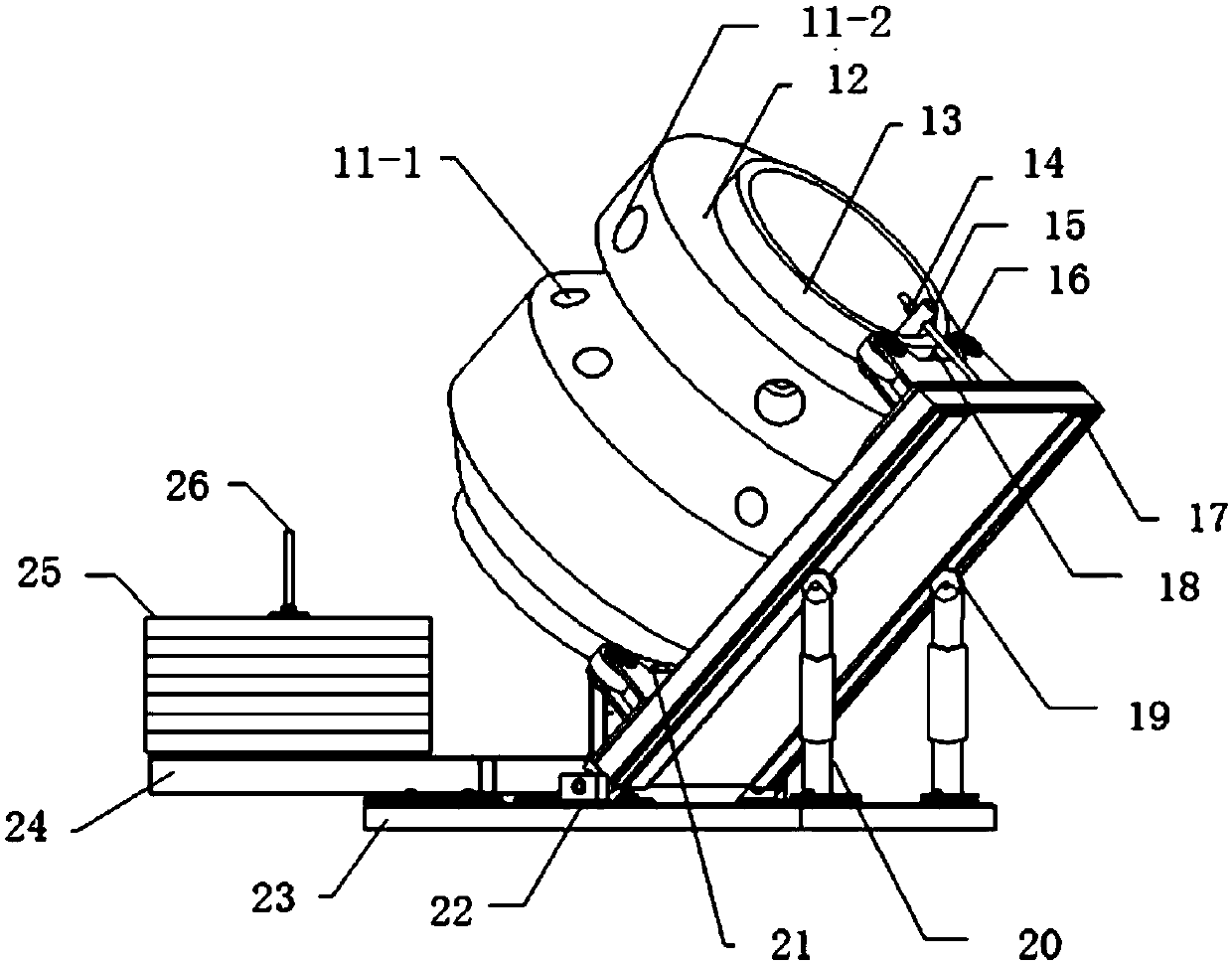

[0066] A typical implementation, such as figure 1 As shown, a processing device includes a rotating mechanism 5 and a clamping part 6 .

[0067] The rotating mechanism 5 is fixed on the base 4, and the driving device (set inside the rotating mechanism 5) drives the rotating mechanism 5 to rotate along its central axis. The driving device is preferably a servo motor, and the clamping part 6 is arranged on the rotating mechanism 5.

[0068] A three-dimensional motion mechanism 1 may also be included.

[0069] The support column 3 is rotatably connected to the base 4, and the moving beam 10 is slidably connected to the side end surface of the support column 3 through the guide slide 9. The driving device drives the support column 3 to rotate along its own axis, and the support column 3 can rotate along its own axis, move The beam 10 can move horizontally and vertically.

[0070] In other embodiments, the three-dimensional motion mechanism 1 can be replaced with other forms, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com