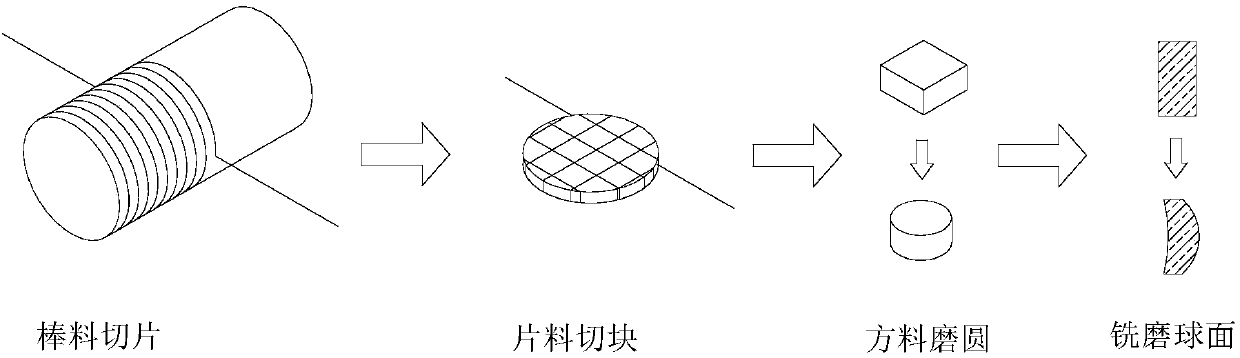

Glass optical element blank preparation device and method thereof

A technology for optical components and preparation devices, applied in glass manufacturing equipment, glass molding, glass re-molding, etc., can solve the problems of large material loss, slow material flow, high cost, and achieve improved compactness, increased flow speed, Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

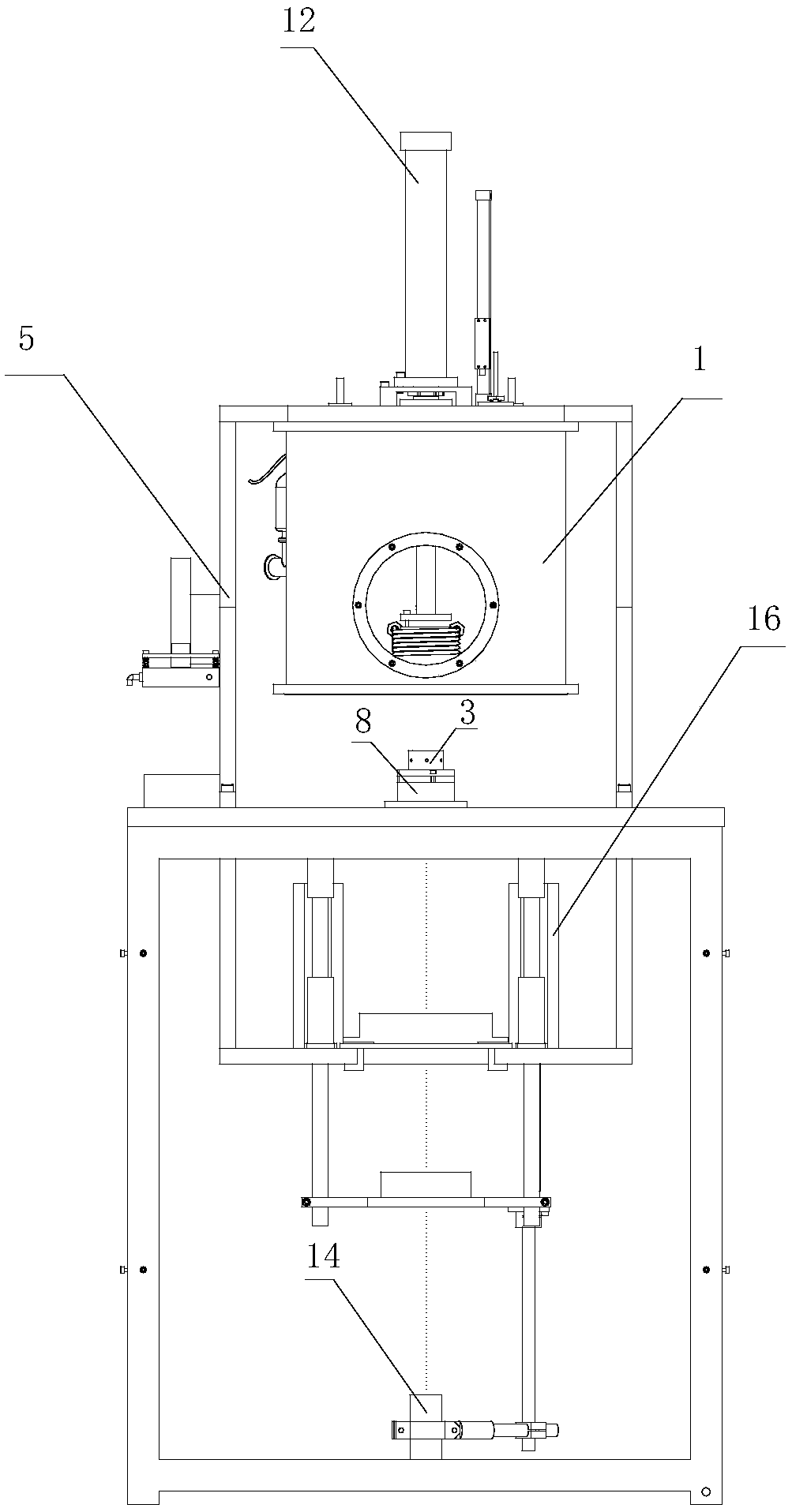

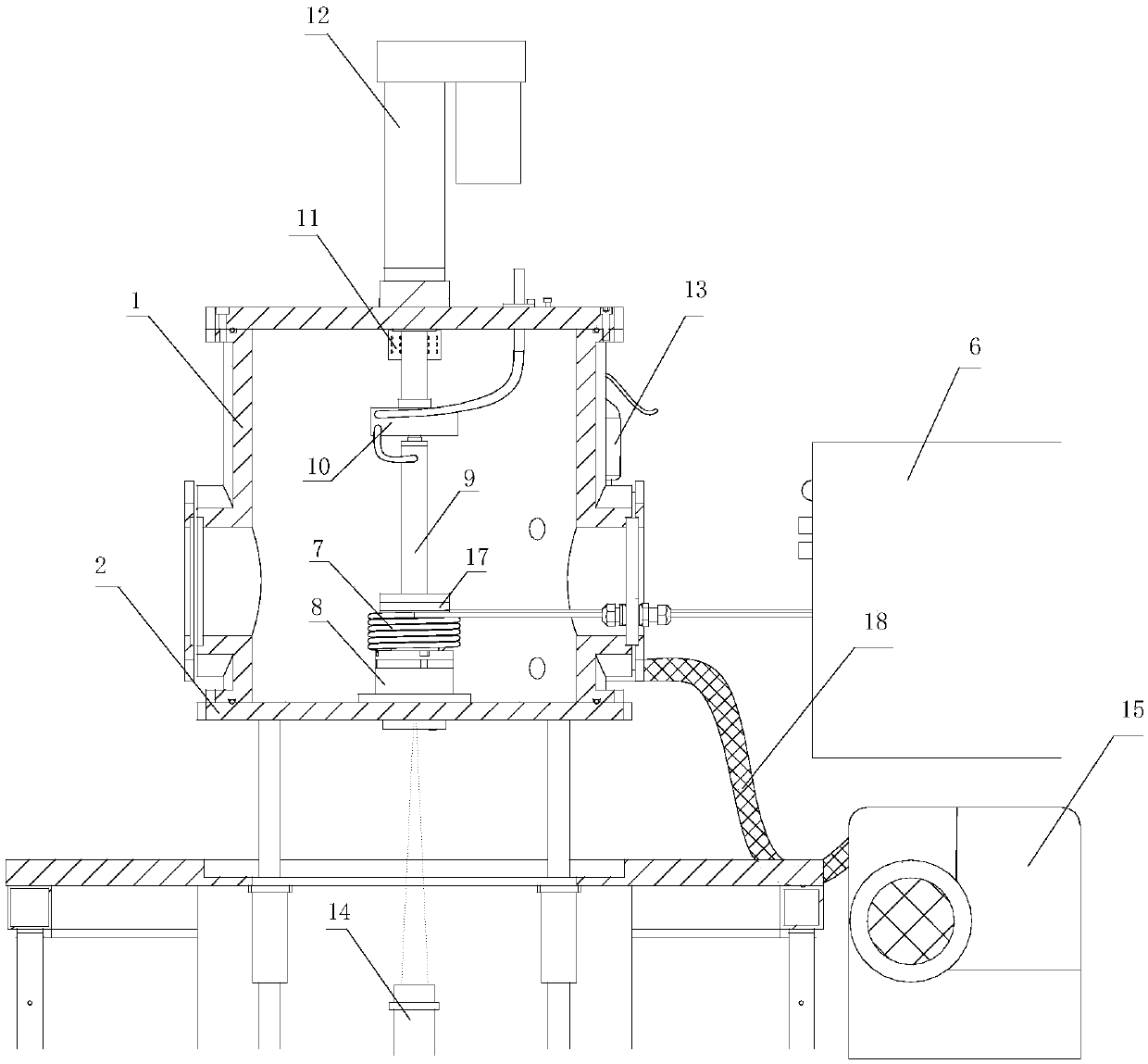

[0027] Such as Figure 2-5 As shown, the device of the present invention includes a frame 5, a sealing cover 2, a sealing cabin 1, a vacuum machine 15, a nitrogen diffuser 11, an induction heater 6, a heating ring 7, a workbench 8, a pressing mechanism, and an infrared thermometer 14 , rising cylinder 16 and mold 3, wherein, sealing cabin 1 is arranged on the frame 5, and sealing cover 2 and sealing cabin 1 are matched and sealed when working, and sealing cover 2 is supported and promoted by rising cylinder 16, and mold 3 is arranged on workbench 8 Above, the working table 8 is set on the sealing cover 2, the vacuum machine 15 communicates with the inside of the sealing cabin 1 through the conduit 18, the nitrogen diffuser 11 is arranged in the sealing cabin 1, and the heating ring 7 is arranged in the sealing cabin 1 and is located on the working table 8 Directly above, the induction heater 6 controls the heating ring 7 to heat, and the pressing mechanism is located directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com