Gasoline deep desulfurization method and equipment for gasoline deep desulfurization

A deep desulfurization and gasoline technology, applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problems of reduced extraction of sulfide, unfavorable hydrogenation unit, and many impurities, and achieve the effect of avoiding large losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0107] In the present invention, there is no special limitation on the preparation method of the adsorbent, and there is no special limitation on the shape of the adsorbent.

[0108] Preferably, the sulfur content in the adsorbed light fraction obtained after the adsorbent adsorption step is ≯10 μg / g.

[0109] Preferably, the method of the present invention further includes: before mixing with the heavy fraction after hydrogenation in step (4), first performing etherification reaction on the sweetened light fraction obtained in step (3), to obtain etherified light fraction; then the etherified light fraction is mixed with the hydrogenated heavy fraction in step (4) to obtain the gasoline product.

[0110] The etherification reaction of the present invention makes it possible to obtain etherified light ends with reduced olefin content and increased octane number.

[0111] The etherification reaction under the preferred circumstances of the present invention is provided below: ...

Embodiment 1

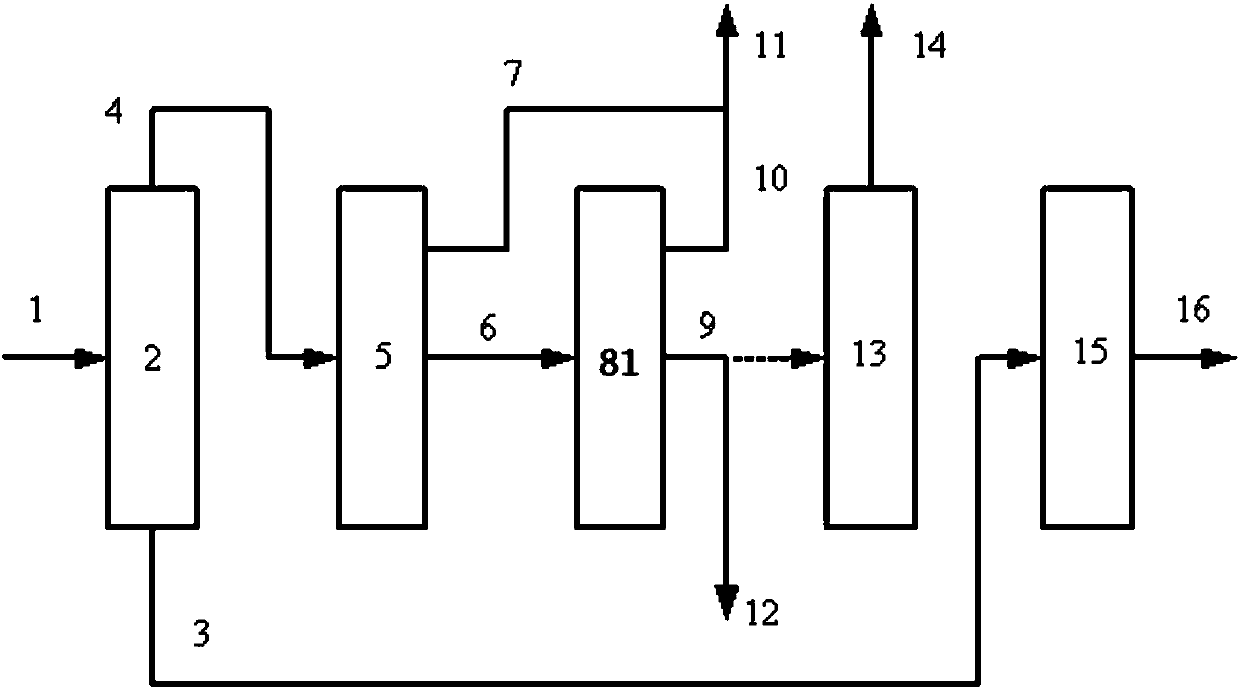

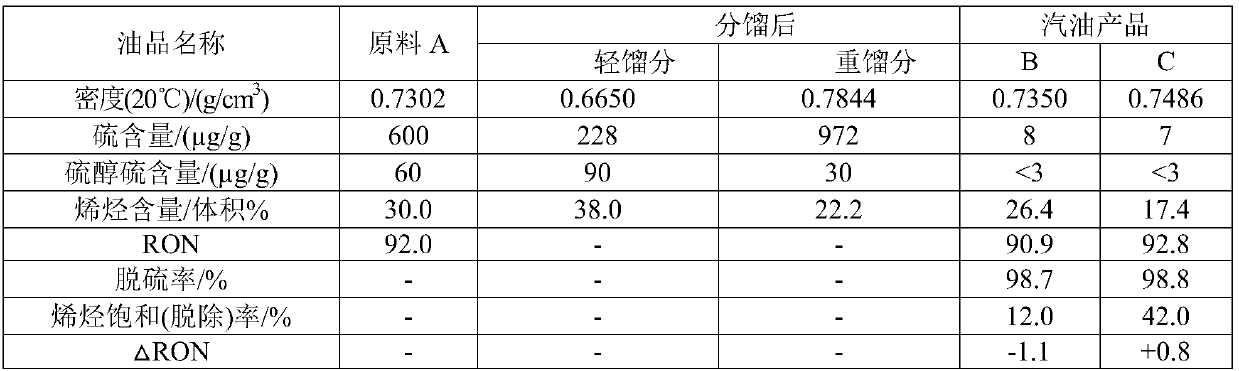

[0180] This embodiment adopts figure 1 The equipment shown in Table 1 performs advanced desulfurization treatment on the gasoline feedstock A.

[0181] Gasoline feedstock A was fractionated at a cut point temperature of 95°C to obtain a yield of 50% by weight of the light fraction and a yield of 50% by weight of the heavy fraction.

[0182] In the solvent extraction system, the fractionated light fraction is subjected to solvent extraction distillation in a solvent extraction distillation tower to obtain the solvent-extracted light fraction and sulfur-containing solvent, and the sulfur-containing solvent is 5% by weight of the total light fraction. Then, in the solvent recovery tower, the sulfur-containing solvent is separated from the sulfide contained therein to obtain the solvent-extracted sulfur-containing material and the recovered solvent from which the sulfide has been removed:

[0183] In the solvent extraction distillation tower: the feed weight ratio of the extracti...

Embodiment 2

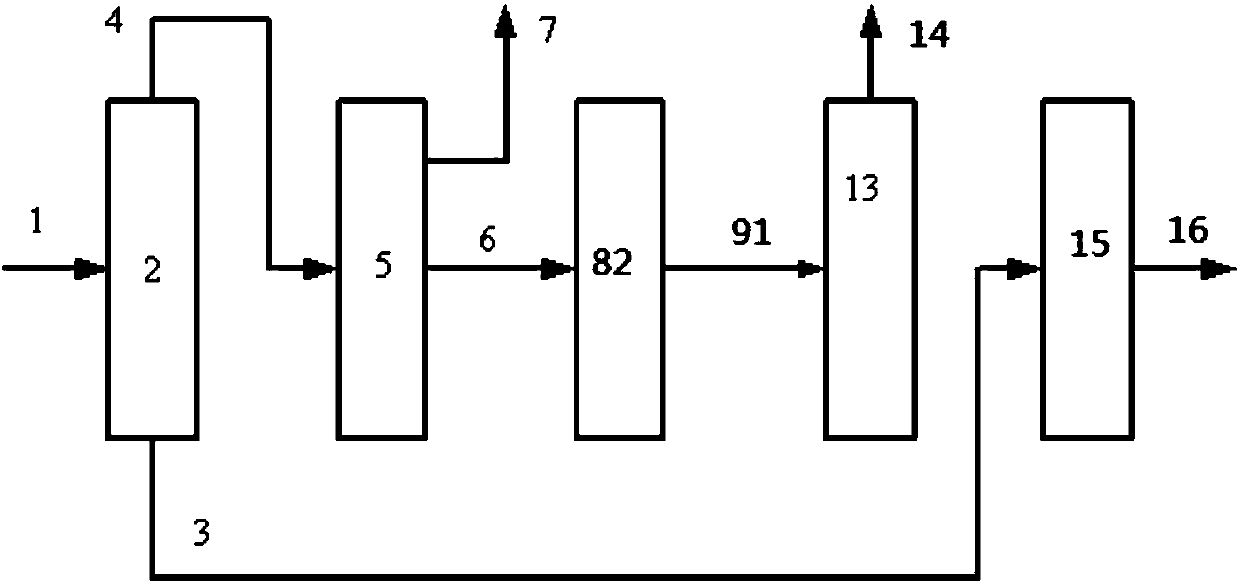

[0209] This embodiment adopts figure 2 The equipment shown is for advanced desulfurization of gasoline feedstock E.

[0210] Gasoline Feedstock E was fractionated at a cut point temperature of 120°C to obtain a yield of 60% by weight of the light fraction and a yield of 40% by weight of the heavy fraction.

[0211] In the solvent extraction system, the fractionated light fraction is subjected to solvent extraction distillation in a solvent extraction distillation tower to obtain the light fraction and sulfur-containing solvent after solvent extraction, and the sulfur-containing solvent is 7% by weight of the total amount of the light fraction . The sulfur-containing solvent is then separated from the sulfide contained therein by distillation in a solvent recovery tower to obtain the solvent-extracted sulfur-containing material and the recovered solvent from which the sulfide has been removed:

[0212] In the solvent extraction distillation tower: the feed weight ratio of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com