Ausforming method capable of improving mechanical property of aluminum alloy rolled plate

A deformation heat treatment and aluminum alloy technology, applied in the field of deformation heat treatment of metal materials, can solve the problems of insignificant improvement of mechanical properties, long process cycle, low efficiency, etc., and achieve the effect of shortening process cycle, simple operation and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

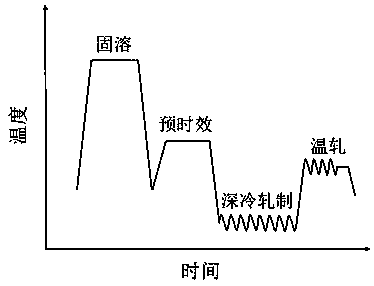

[0019] according to figure 1 In the deformation heat treatment process shown, the material used is 6016 aluminum alloy with a thickness of 10mm. Firstly, the 6016 aluminum alloy is subjected to solution treatment at 560°C / 1h, and water quenched to room temperature; the solid solution aluminum alloy material is immediately subjected to 180°C / 10min pre-aging treatment; and then the pre-aging aluminum alloy material is subjected to cryogenic rolling, rolling An ordinary two-roll mill is used for the production, the cryogenic rolling temperature is controlled at -160°C by liquid nitrogen, the deformation amount of each pass is 5%, and the total deformation amount is 50%; finally, the cryogenically rolled aluminum alloy material is subjected to warm rolling deformation , The warm rolling temperature is controlled at 140°C by an oil bath, the deformation of each pass is 10%, the total deformation is 80%, and the total deformation of cryogenic rolling and warm rolling is 90%.

[002...

Embodiment 2

[0022] according to figure 1 In the deformation heat treatment process shown, the material used is 6016 aluminum alloy with a thickness of 10mm. First, the 6016 aluminum alloy is subjected to solution treatment at 560°C / 1h, and quenched to room temperature; the solid solution aluminum alloy material is immediately subjected to 170°C / 15min pre-aging treatment; then the pre-aging aluminum alloy material is subjected to cryogenic rolling, rolling An ordinary two-roll rolling mill is used for the production, the cryogenic rolling temperature is controlled at -160°C by liquid nitrogen, the deformation amount of each pass is 5%, and the total deformation amount is 60%; finally, the cryogenically rolled aluminum alloy material is subjected to warm rolling deformation , The warm rolling temperature is controlled at 130°C by an oil bath, the deformation of each pass is 10%, the total deformation is 80%, and the total deformation of deep cold rolling and warm rolling is 92%.

[0023] T...

Embodiment 3

[0025] according to figure 1 In the deformation heat treatment process shown, the material used is 6016 aluminum alloy with a thickness of 10mm. Firstly, the aluminum alloy is subjected to solution treatment at 560°C / 1h, and water quenched to room temperature; the solid solution aluminum alloy material is immediately subjected to 180°C / 10min pre-aging treatment; then the pre-aging aluminum alloy material is subjected to cryogenic rolling, rolling Using an ordinary two-roll mill, the cryogenic rolling temperature is controlled at -160°C by liquid nitrogen, the deformation of each pass is 5%, and the total deformation is 45%; finally, the cryogenically rolled aluminum alloy material is subjected to warm rolling deformation, The warm rolling temperature is controlled at 150°C by an oil bath, the deformation in each pass is 10%, the total deformation is 85%, and the total deformation in deep cold rolling and warm rolling is 92%.

[0026] The room temperature mechanical properties...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com