Physical vapor deposition device and method

A physical vapor deposition, vapor deposition technology, applied in ion implantation plating, metal material coating process, coating, etc., to achieve the effect of improving product yield, reducing temperature difference, and reducing temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

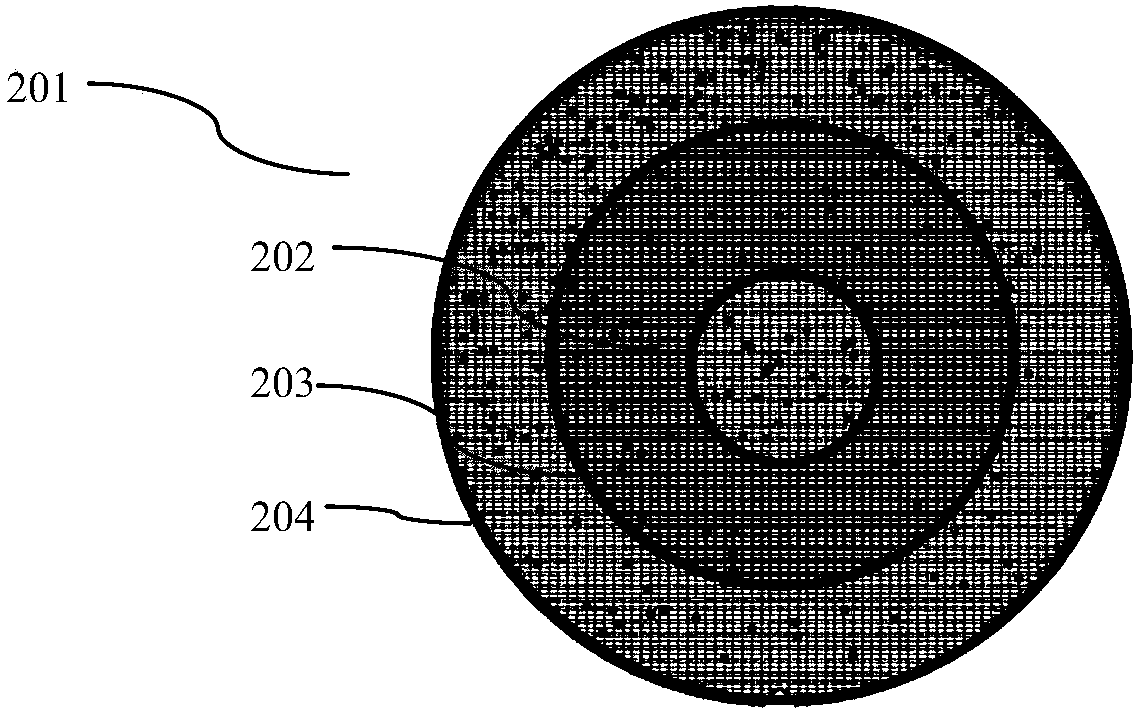

[0037] The technical solution of the embodiment of the present invention is designed for the technical problem to be solved after an in-depth analysis of the technical problem proposed by the present invention, so before introducing the technical solution of the embodiment of the present invention in detail, first introduce the technical problem of the present invention. and its analysis process:

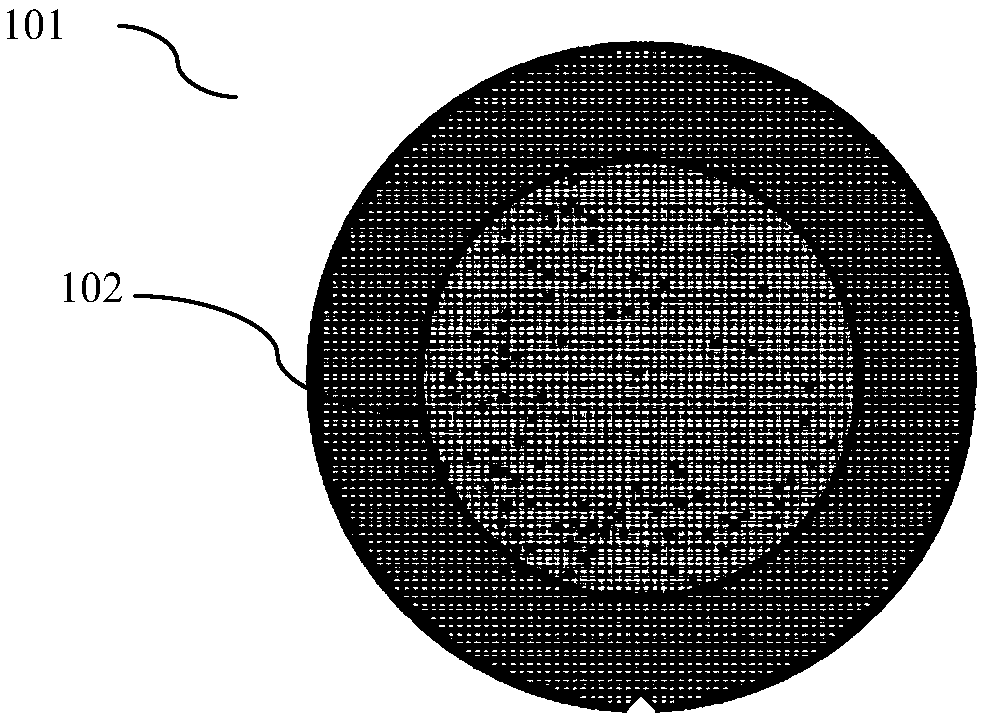

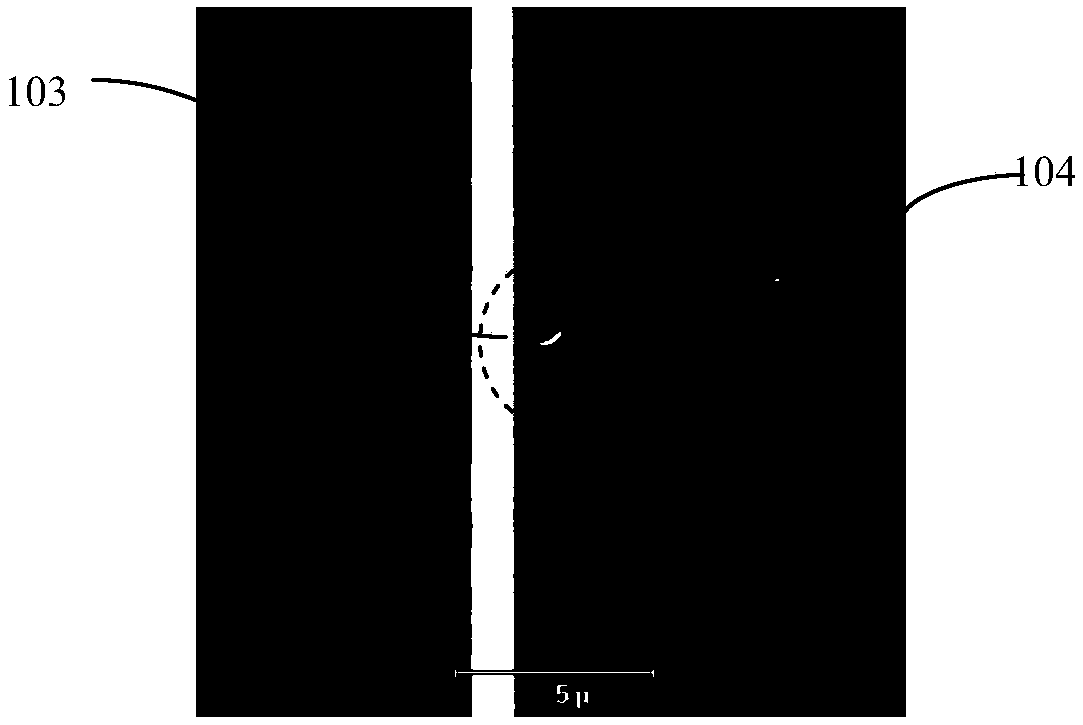

[0038] With the development of integrated circuit technology and the increase of wafer size, semiconductor production puts forward higher requirements for temperature uniformity in the process of thin film deposition. At present, the physical vapor deposition thickness of aluminum in the back-end of the semiconductor is relatively large, and the operating temperature is relatively high. During the operation process, there is a certain gradient in the temperature of the entire wafer. Due to the sensitivity of the aluminum deposition layer to temperature differences, hilly defects are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com