A tunnel lining structure and construction method filled with ceramsite

A technology of ceramsite and tunnel, which is applied in the field of tunnel lining structure and construction, which can solve the problems of large deformation of tunnel surrounding rock, extrusion deformation damage, and absence of equipment, etc., and achieve the effects of reduced strength, low self-weight, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

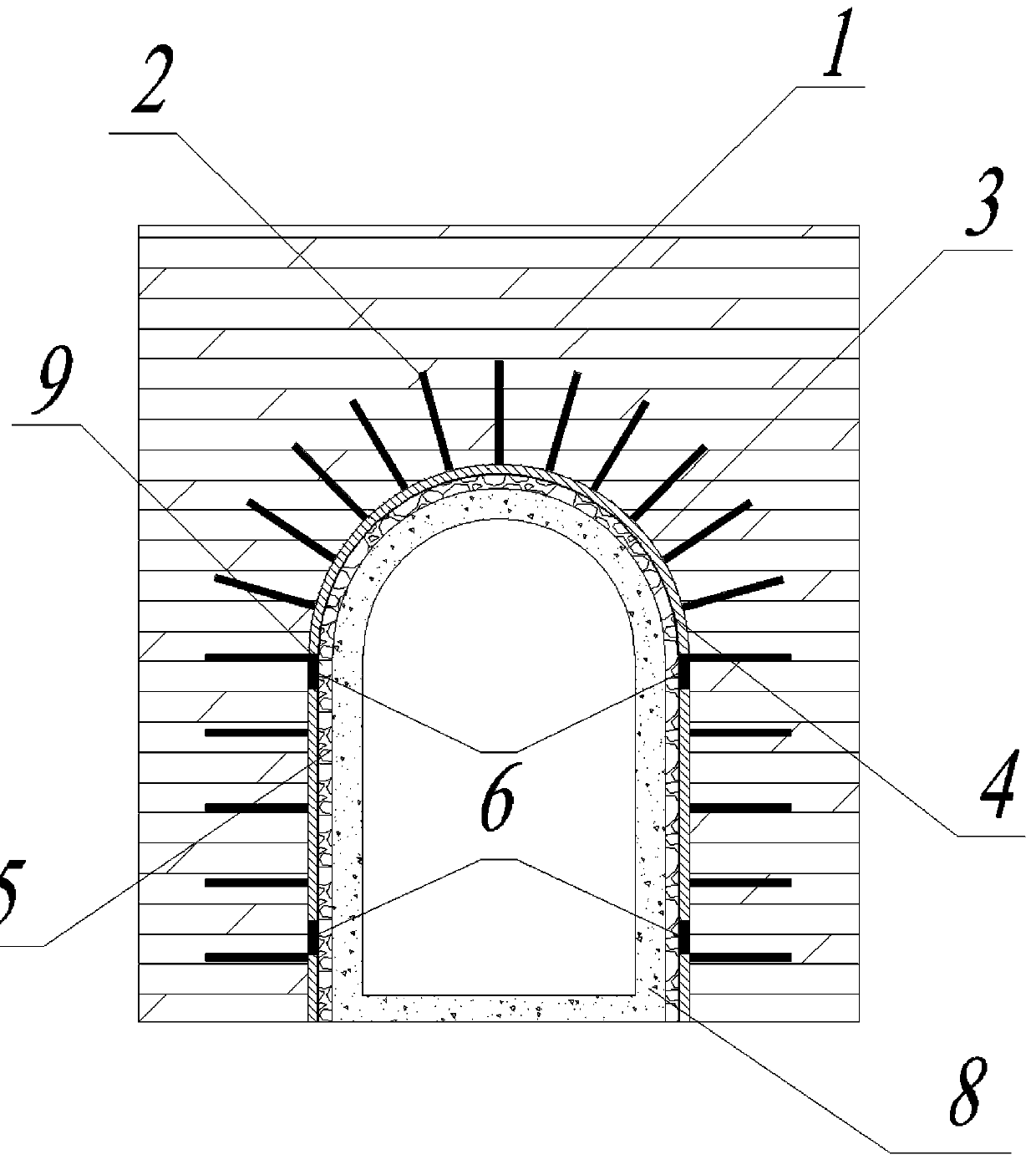

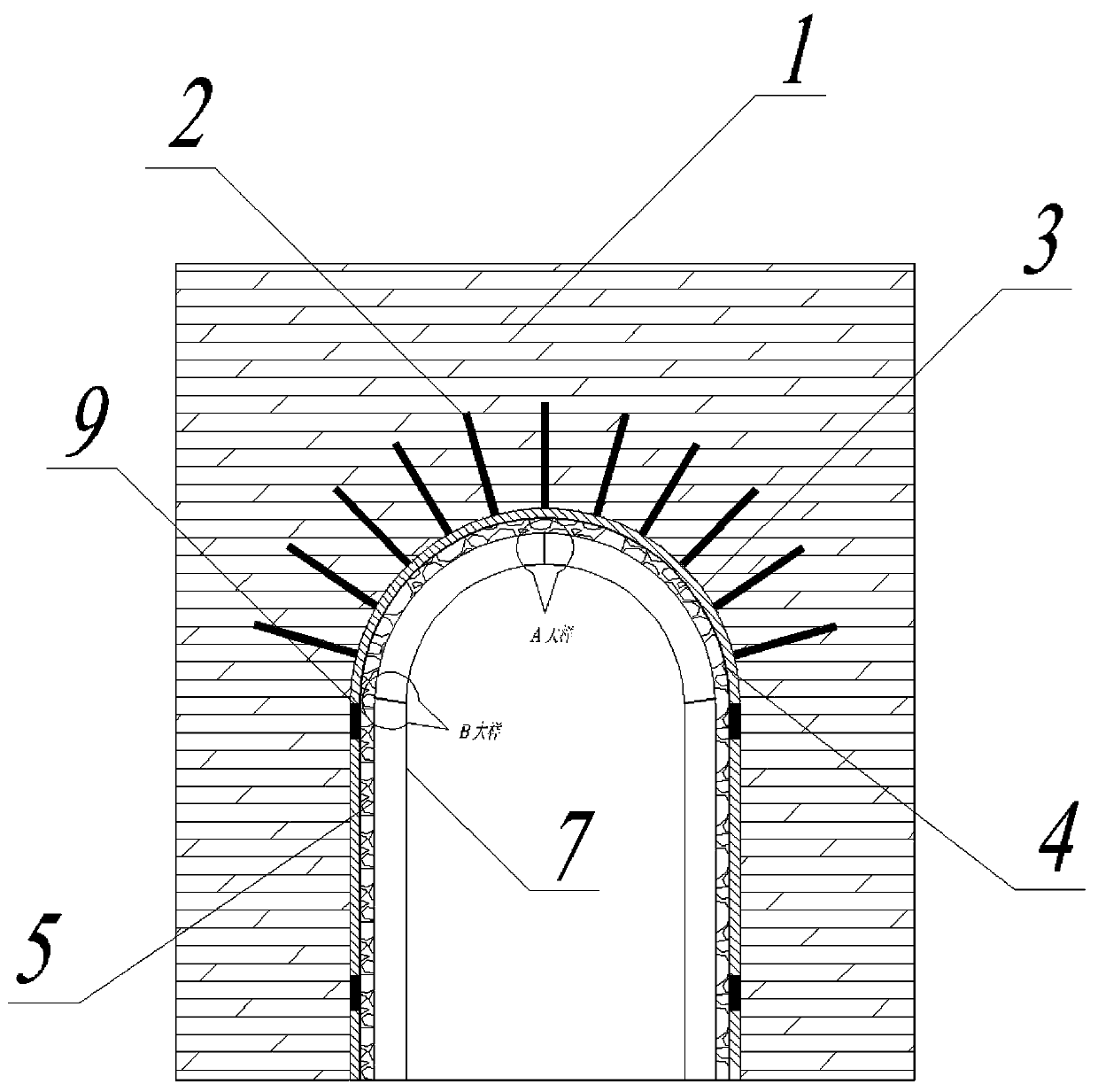

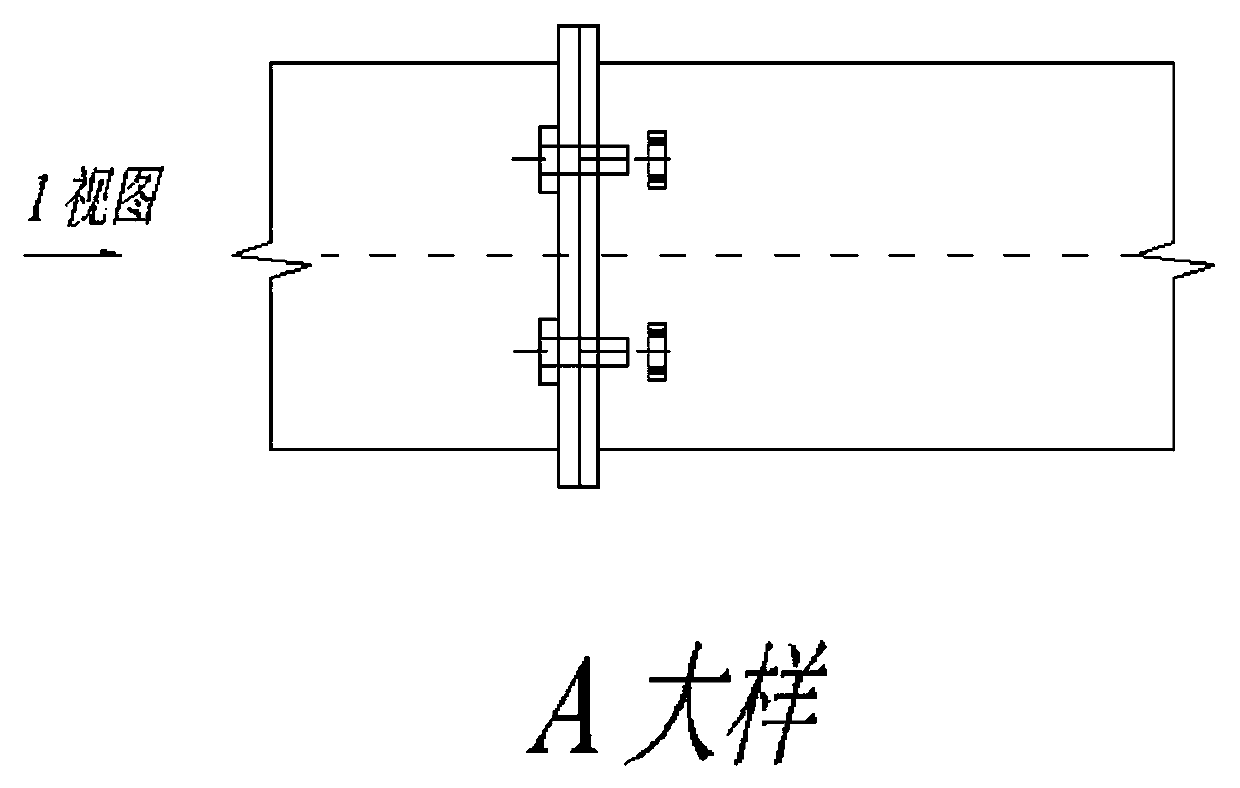

[0039] like Figure 1-8 , a tunnel lining structure filled with ceramsite, which includes a surrounding rock 1, primary support 3 is anchored on the tunnel rock mass of the surrounding rock 1 through bolts 2, and the inner layer of the primary support 3 is laid There is a waterproof layer 4, on the inner layer of the waterproof layer 4, a ceramsite filler 5 is laid, a steel arch 7 is set inside the ceramsite filler 5, and a secondary lining 8 is poured inside the steel arch 7. By adopting the above-mentioned tunnel lining structure, the initial support 3 is implemented in time after the tunnel is excavated, and the basic form is shotcrete and the anchor rod 2, and then the ceramsite filler 5 is set on the basis of the reserved deformation joints as the filling type. Lining, followed by the laying of the waterproof layer 4, the secondary lining 8 adopts the form of erecting steel arches and pouring integral molded concrete to give full play to the bearing capacity of the surrou...

Embodiment 2

[0050] Any construction method using ceramsite-filled tunnel lining structure is characterized in that it includes the following steps:

[0051] Step1: Before excavating the tunnel, grouting is applied to radially advanced small conduits. The small conduits are seamless steel pipes with a diameter of 30-50mm and a length of 25-40mm. Test confirmed, using high-pressure grouting pump grouting;

[0052] Step2: After the excavation of the tunnel, implement the initial support 3 in time, install the steel mesh, set the anchor rod 2, mix the concrete mixture mixed with the quick-setting agent and water into a slurry, and spray it on the wall of the tunnel to condense;

[0053] Step3: Install the automatic pressure gauge 6 to measure the deformation of the surrounding rock;

[0054] Step4: Lay the waterproof layer 4, adopt the membrane waterproof layer, and lay it on the entire section of the arch and the side wall. The material is geotextile and waterproof board, and set the system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com