Detection method of wall deformation

A detection method and wall technology, which is applied in the detection of wall deformation and safety detection, can solve the problems of continuity, usability, reliability, accuracy and efficiency, damage of building wall structure, detection wave attenuation, etc. , to achieve the effect of realizing early warning of building safety, ensuring urban safety, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

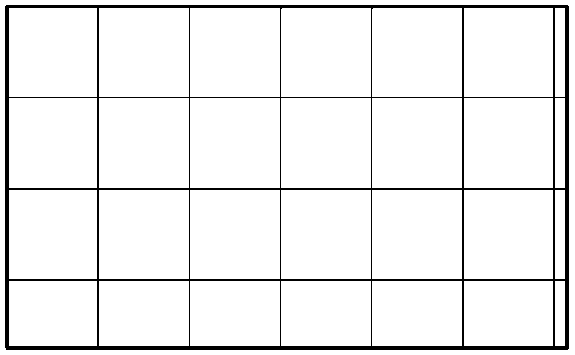

[0024] ①Confirm the wall material and wall size of the wall to be tested, and confirm that the area of the wall is 30m 2 ,according to figure 1 The pattern divides the wall into several square units in the test area, and the area of each unit is 4m 2 , use the infrared thermal imager to measure the wall in each grid unit in turn, use the temperature and humidity recorder to record the real temperature of the wall before the measurement, and then use the infrared thermal imager to measure the wall, when measuring , keep the temperature and humidity recorder to record samples, set the sampling interval to 5S, and image each grid cell separately.

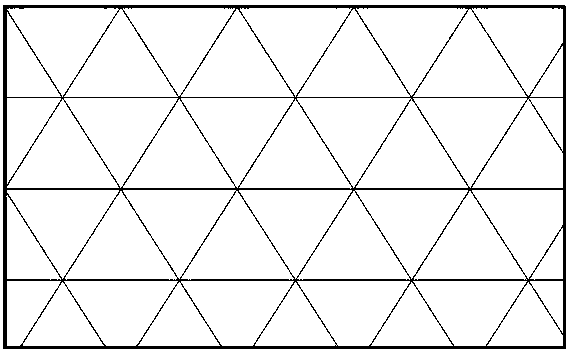

[0025] ② Then follow figure 2 The pattern divides the wall into several equilateral triangle units in the test area, and the area of each unit is 3m 2 , use the infrared thermal imager to measure each equilateral triangle unit in turn. The thermal imager is at a 45° oblique angle to the wall plane, and the temperature and hu...

Embodiment 2

[0029] ①Confirm the wall material and wall size of the wall to be tested, and confirm that the area of the wall is 76m 2 ,according to figure 1 The pattern divides the wall into several square units in the test area, and the area of each unit is 8m 2, use the infrared thermal imager to measure the wall in each grid unit in turn, use the temperature and humidity recorder to record the real temperature of the wall before the measurement, and then use the infrared thermal imager to measure the wall, when measuring , keep the temperature and humidity recorder to record samples, set the sampling interval to 15S, and image each grid cell separately.

[0030] ② Then follow figure 2 The pattern divides the wall into several equilateral triangle units in the test area, and the area of each unit is 6m 2 , use the infrared thermal imager to measure each equilateral triangle unit in turn. The thermal imager is at a 45° oblique angle to the wall plane, and the temperature and hu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com