An assembled integral subway station model structure and its manufacturing method

A technology for subway station and model structures, which is applied in the field of assembling integral subway station model structures and its manufacture, which can solve the problems of small geometric size of model structures, large scale ratio, limited size or bearing capacity, etc., and achieves simple and easy manufacturing methods Effective, economical and reliable, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

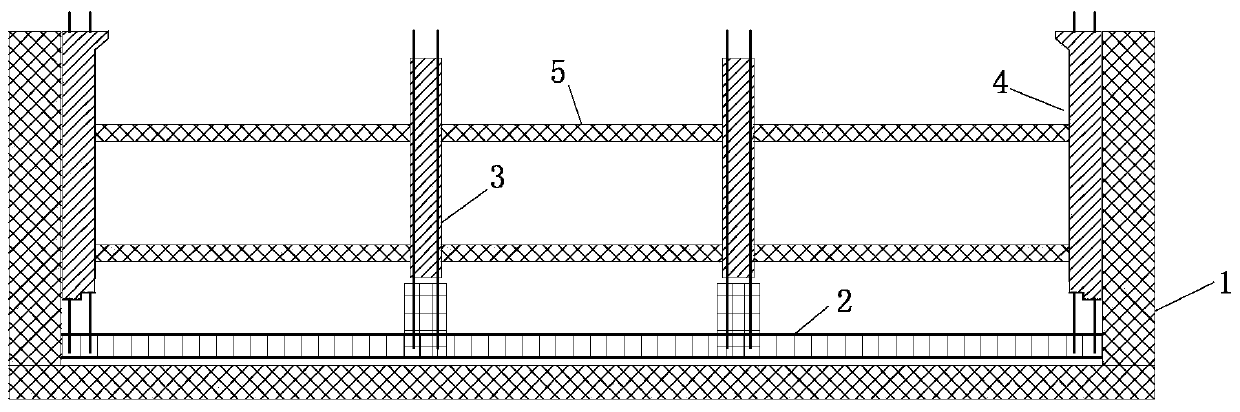

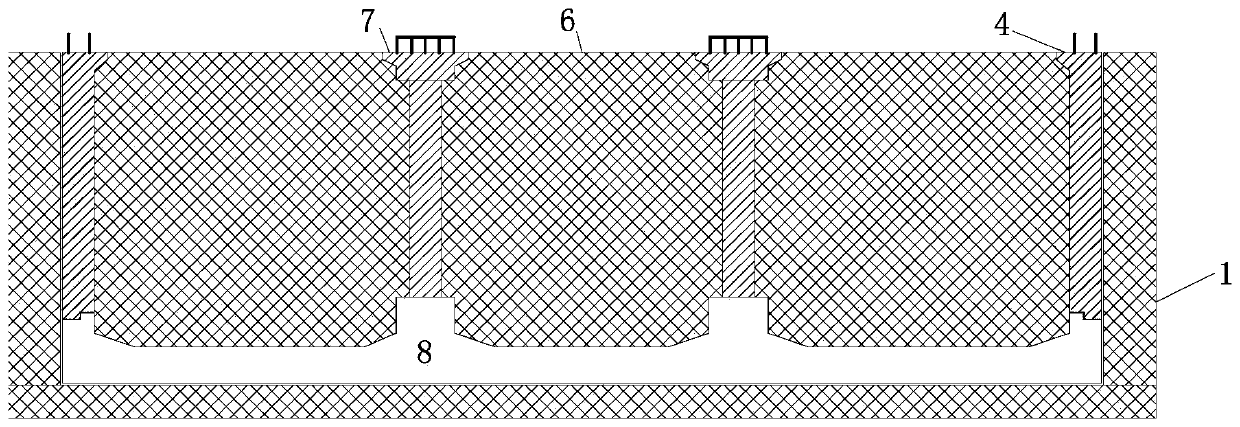

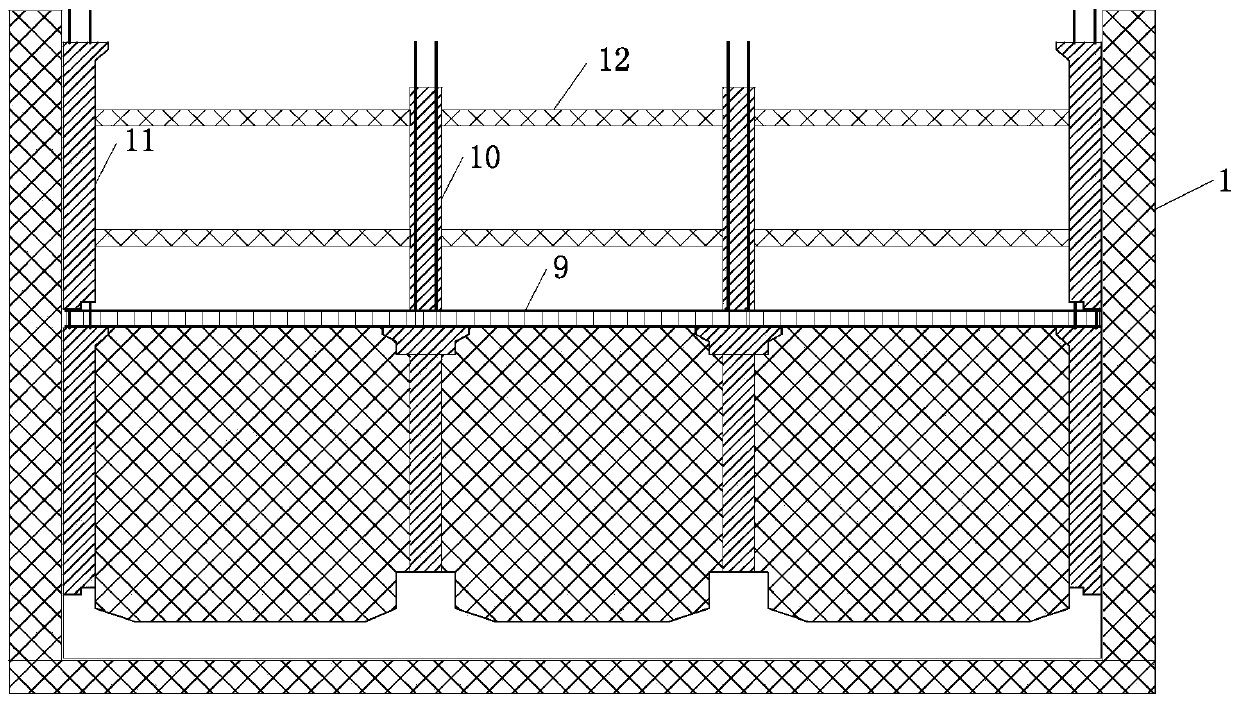

[0043] The new prefabricated integrated subway station structure includes discrete prefabricated walls, prefabricated columns, prefabricated beams and other prefabricated components, as well as post-cast slabs and other cast-in-place components. Discrete prefabricated walls, prefabricated columns, and prefabricated beams are connected by steel connectors and formed as a whole by cast-in-place components.

[0044] Model test is a conventional method to study or evaluate the structural characteristics or certain mechanical properties of building structures in the field of civil engineering. If the prototype structure is an assembled monolithic subway station structure, and when there is a demand for model testing, a kind of assembled monolithic subway station model structure and its manufacturing method described in the present invention can be used.

[0045]Model structure is the core and key of model testing. When the model structure is made, it must be redesigned according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com