Semiautomatic hydraulic water softener

A water softener, semi-automatic technology, applied in the direction of filter regeneration, water/sewage treatment, chemical instruments and methods, etc., to achieve the effect of solving pollution problems and uniform salt density

Inactive Publication Date: 2018-05-11

COWAY CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0019] Specifically, the present invention proposes a sheet-type regenerant to overcome the problems of block-type regenerants and powder-type regenerants

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0042] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

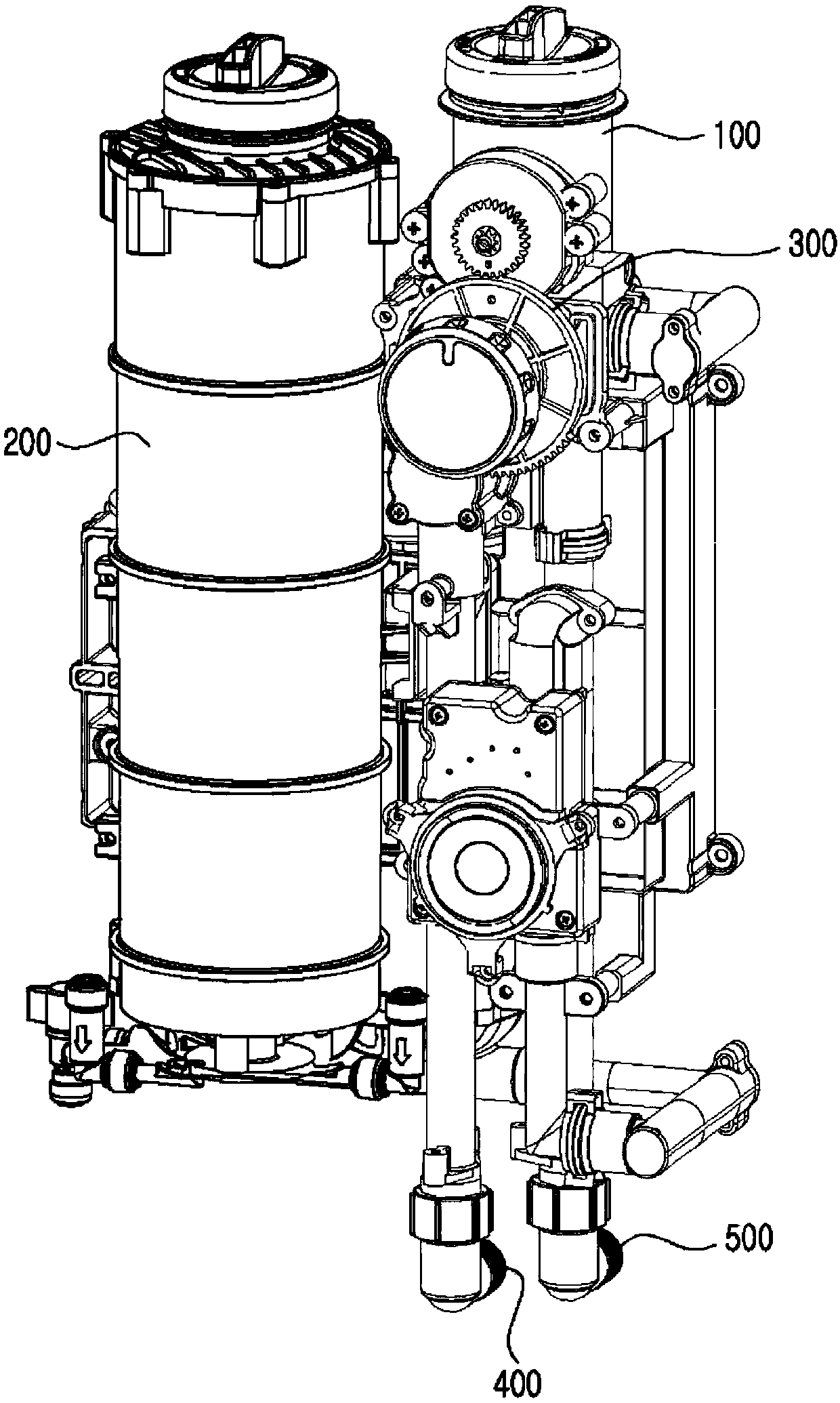

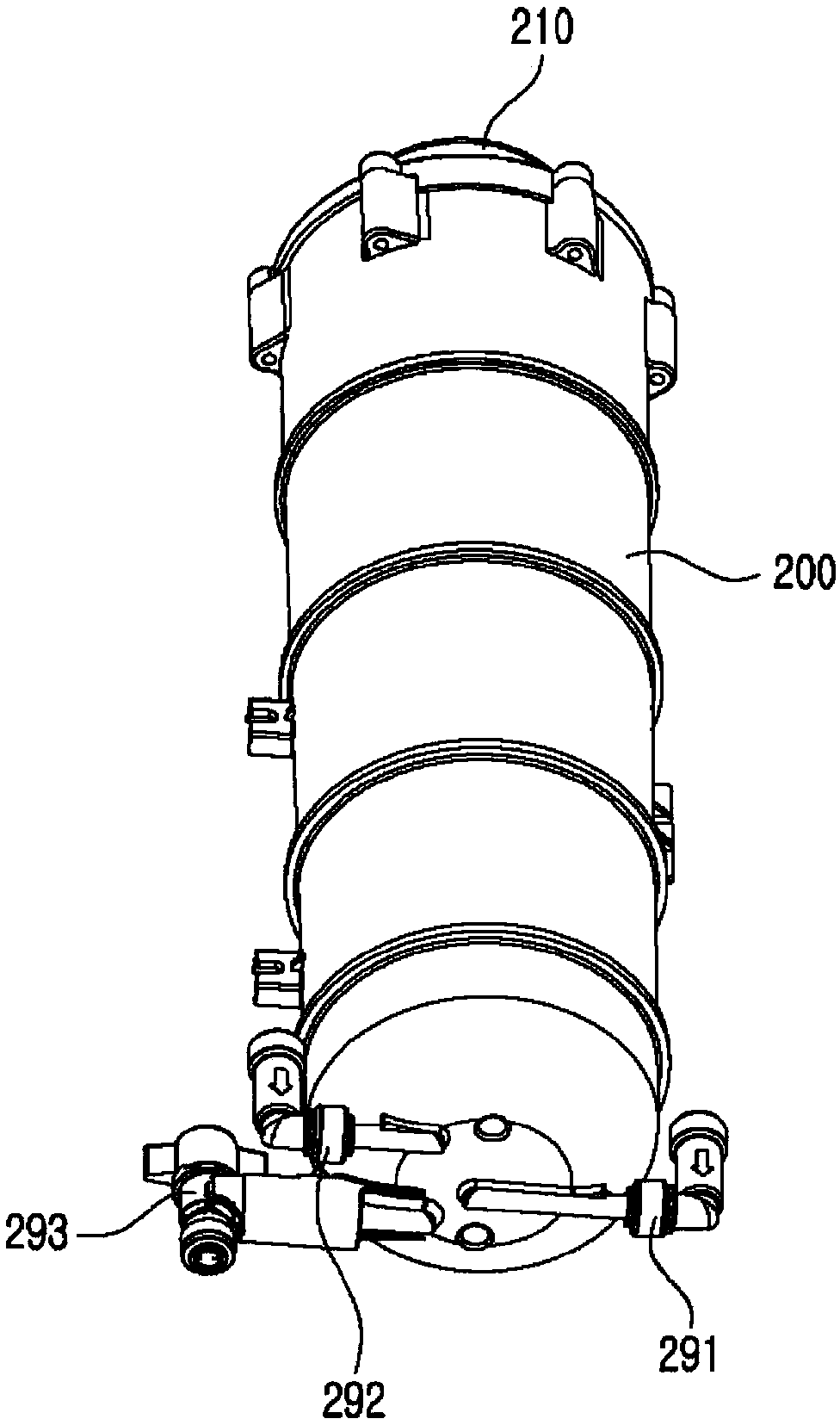

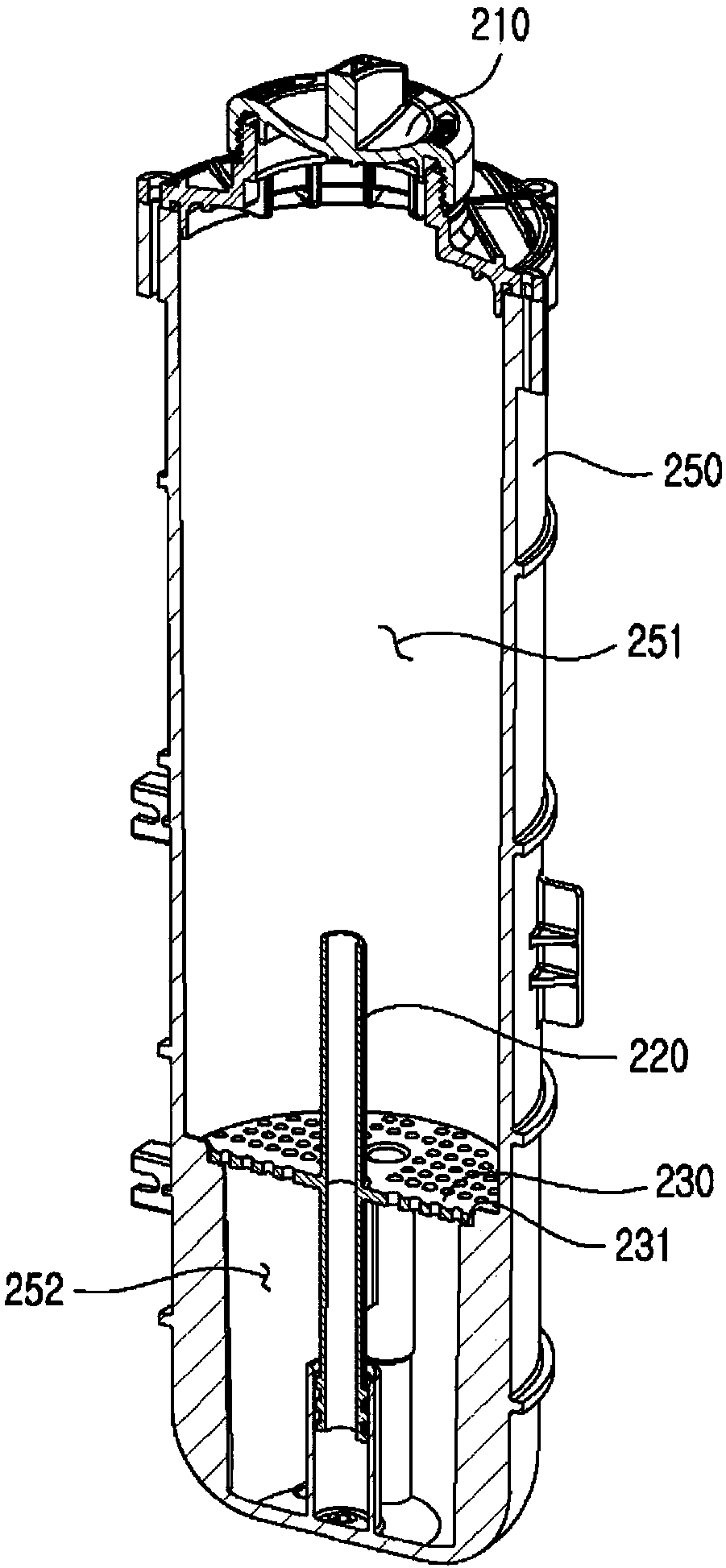

The present invention provides a semiautomatic hydraulic water softener which is a water softener comprising: an ion resin tank (100) having ion resin; a regenerant container (200) in which a regenerant can be introduced in order to produce reclaimed water capable of filling the ion resin; a drain valve (293) provided on the regenerant container (200) in order to externally drain residual water; awater introducing part (400) for selectively supplying raw water to the ion resin tank (100) and the regenerant container (200); and a timer and a ceramic disk switching valve (300) for selecting onefrom among a water softening mode, a raw water mode, and a regenerating mode, and changing passages between the water introducing part (400), the ion resin tank (100), and the regenerant container (200). When the water softener is in regenerating mode, one from among a first mode and a second mode is selected according to a preset method, wherein the first mode is implemented during a preset timeby the timer and ceramic disk switching valve (300), and when raw water is supplied to the regenerant container (200) to produce reclaimed water, the drain valve (293) is opened in the second mode.

Description

technical field [0001] The invention relates to a semi-automatic hydraulic water softener. More particularly, the present invention relates to a water softener that can use residual water as regenerated water or discharge residual water according to mode selection. Background technique [0002] Tap water (hereinafter referred to as hard water) includes a large amount of chloride ions in the purification process, and when the tap water passes through old pipes or the tap water itself is seriously polluted, various heavy metal ions harmful to the human body are contained in the tap water, such as iron, zinc, lead and mercury. In particular, ionic components can combine with fatty acids in soap to produce metal foreign matter, and fatty acids may contact the skin, causing skin allergies or aging. [0003] To prevent this from happening, water softeners pass hard water through strong positive acid ions such as Na + ), making the hard component Ca 2 + and Mg 2+ can be with ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/42B01D35/00B01D35/157B01D35/30B01D41/00B01J49/00

CPCC02F1/42C02F2001/425C02F2301/063C02F2303/16B01J49/75B01J49/50B01D35/157B01D35/30B01D41/02

Inventor 李贤康李星熹金元泰

Owner COWAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com