Method for manufacturing a cooling device for cooling a battery

A cooling device and battery technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of long process time, high manufacturing cost, unfavorable manufacturing process, etc., and achieve the effect of fast and flexible adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

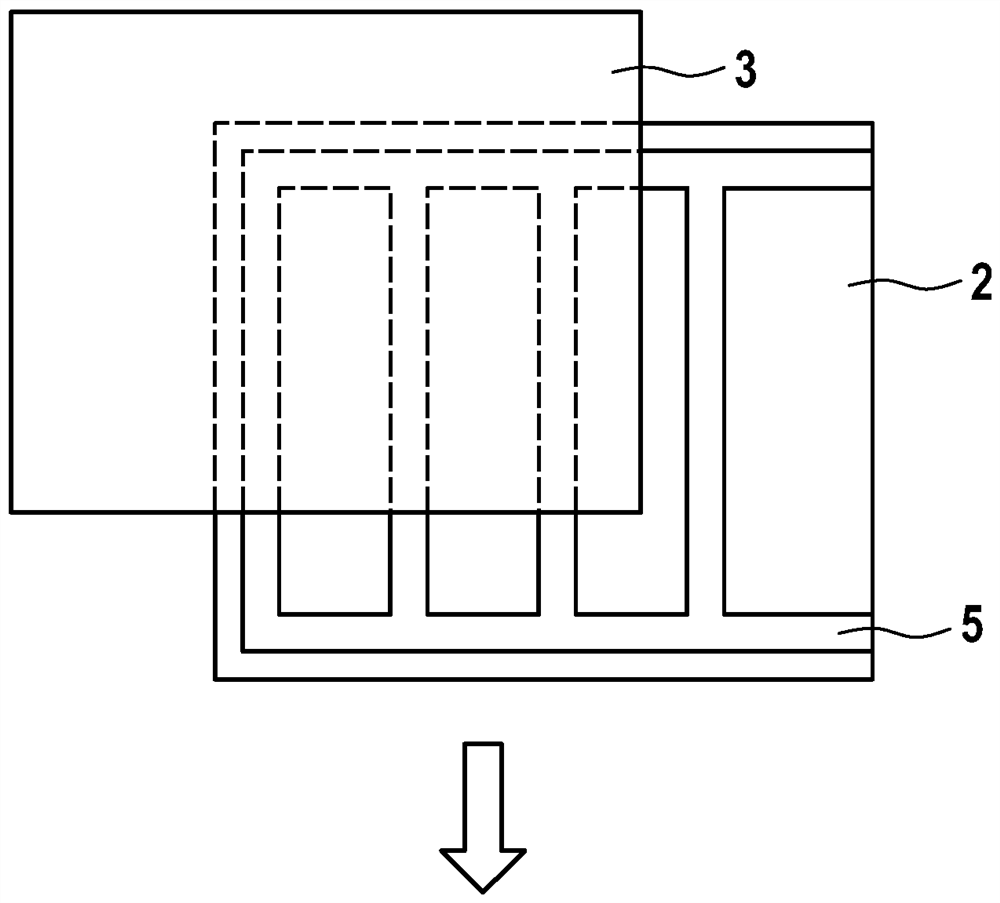

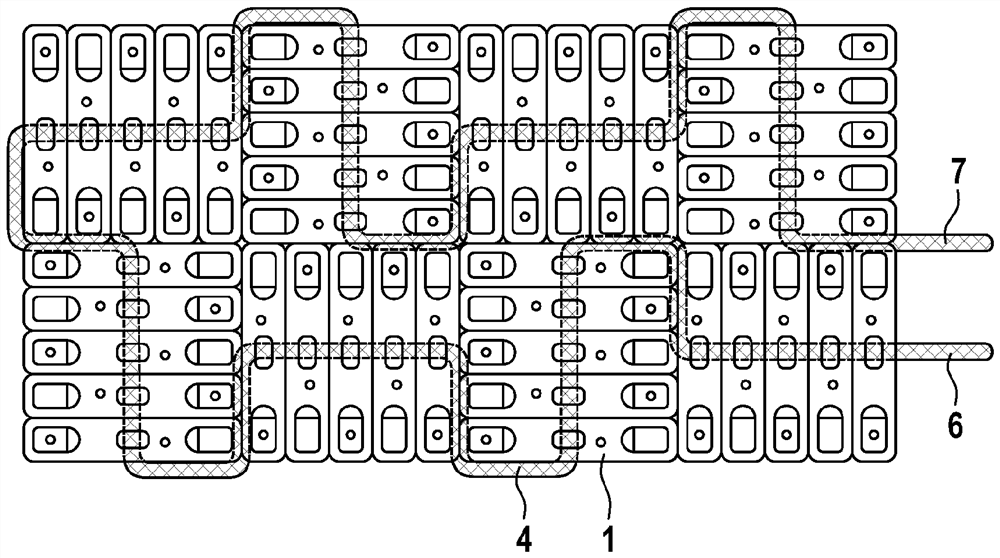

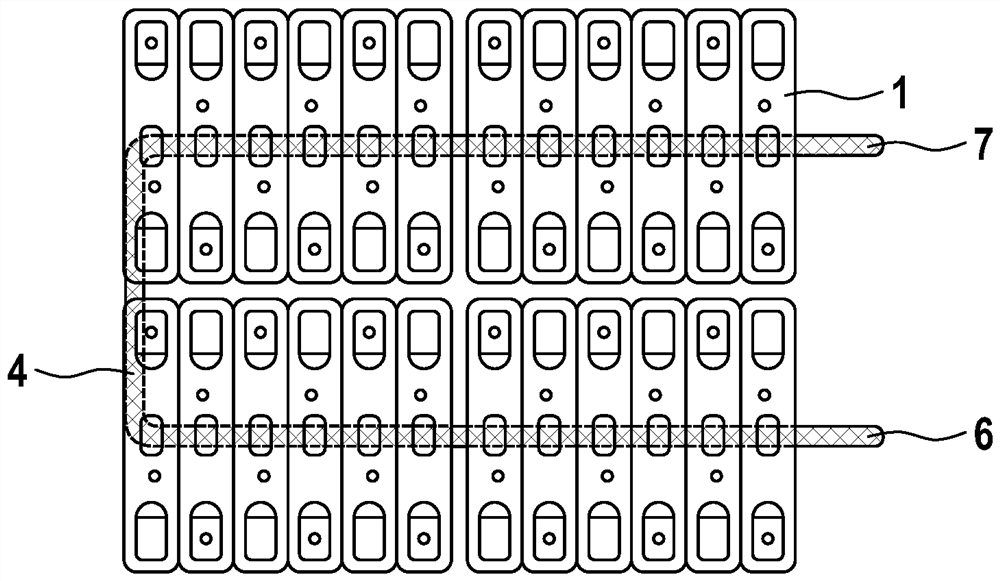

[0028] exist Figures 1 to 3 In the example shown, two sheets 2, 3 are extruded from thin butyl rubber. A means of insulating medium 5 is applied to the first plate 2 . Also, in detail, the not shown inlet zone 6 and outlet zone 7 can be coated (cf. image 3 ). Subsequently, as in figure 2 As shown in , the two plates 2, 3 are joined, for example by vulcanization at high pressure and temperature. Subsequently, as in image 3 As shown in , the corresponding intermediate regions, which are present between the arrangements of the cooling channels 4 , are removed, for example by stamping.

[0029] In this embodiment, it is possible in a development of the invention to introduce additional tissues or the like which improve the image 3 The shape and mechanical strength of the cooling channels are shown in the device.

[0030] is used to generate in figure 2 During the joining process of the device shown in it is possible to fill the means of the cooling channels, for exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com