Sewage filtering device for food processing

A technology of food processing and filtering devices, which is applied in the field of sewage filtering devices for food processing, and can solve the problems of limited use and non-recyclable residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

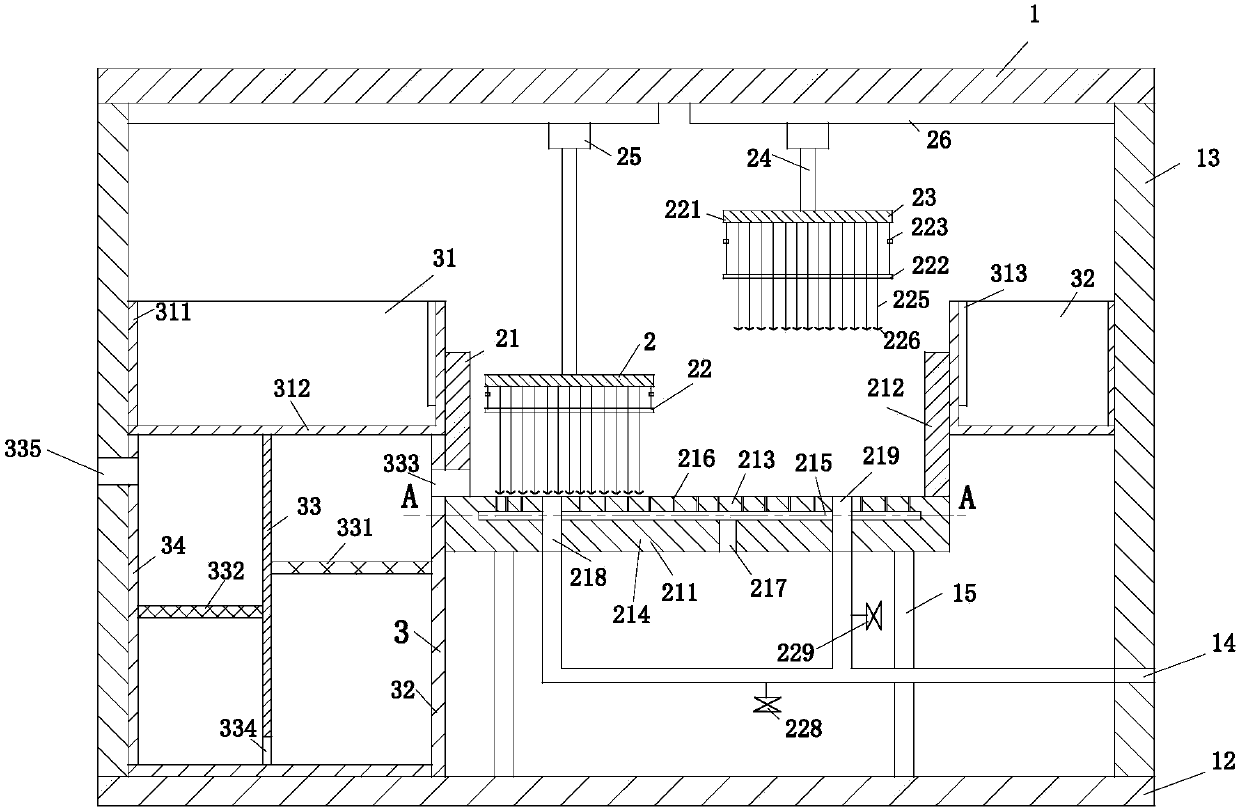

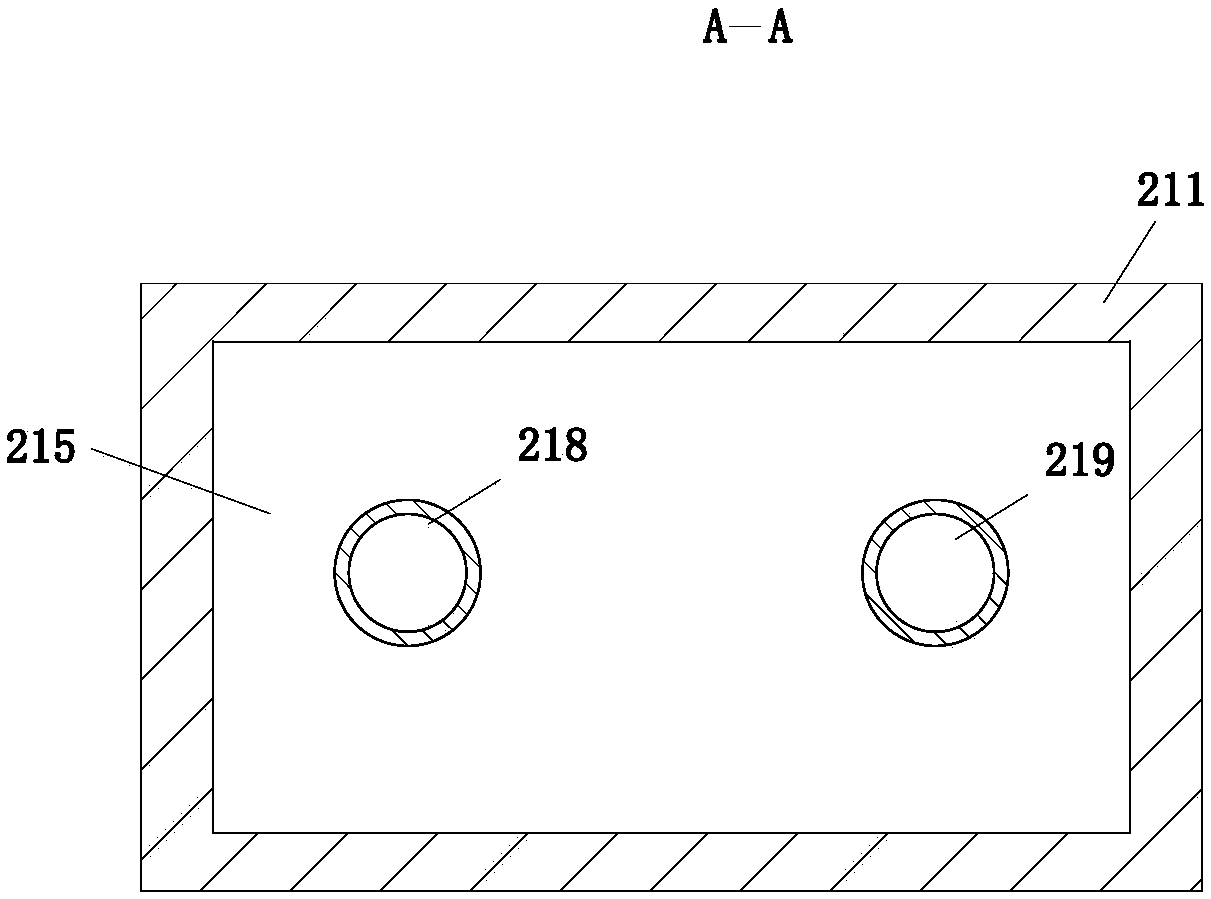

[0030] As an embodiment of the present invention, the No. 1 recovery tank 31 includes a No. 1 side plate 311 and a No. 1 bottom plate 312; the No. 1 side plate 311 is installed on the No. 1 bottom plate 312; the No. 1 side plate 311 The inner surface of the right side plate 13 is provided with a blowing device 313; the blowing device 313 is used to blow the No. 1 brush unit 22;

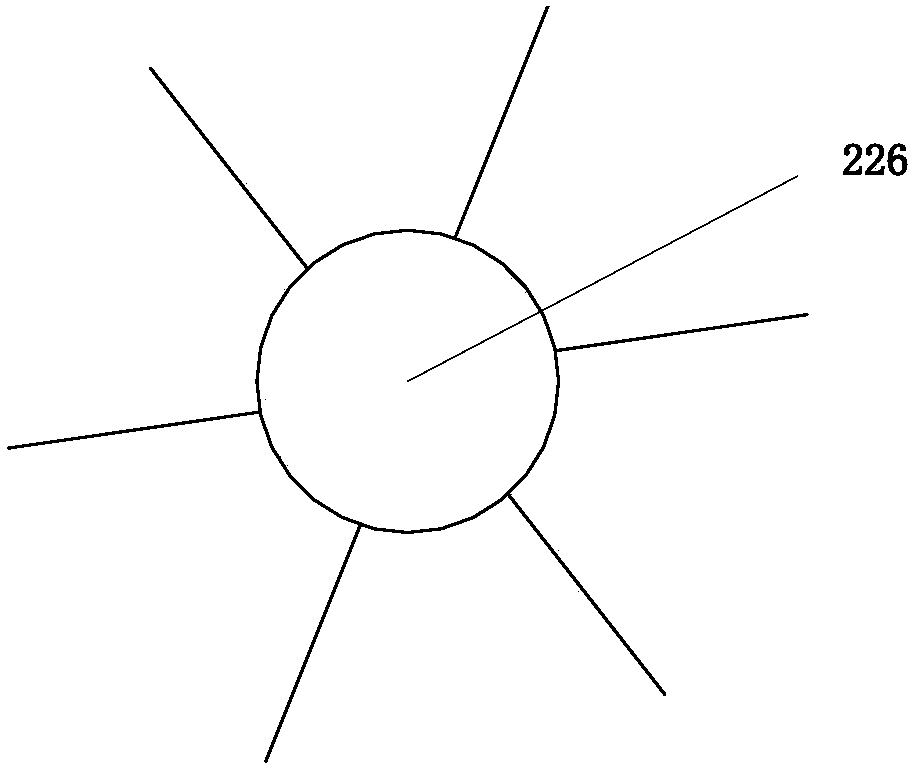

[0031] When the primary plate 221 and the secondary plate 222 in the No. 1 hairbrush unit 22 were attached together, the distance between the brush head 226 and the secondary plate 222 became larger, and the hairbrush 225 became softer; Under the action of device 313, the feathers and hair residues in the gaps of the brushes 225 fall into the No. 1 recovery tank 31; the working mode of the No. 2 brush unit 23 is consistent with that of the No. 1 brush unit 22; Recovery tank 31 and No. 2 recovery tank 32 are used to accelerate No. 1 brush unit 22 and No. 2 brush unit 23 to the processing efficiency of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com