Multifunctional membrane filtering system

A membrane filtration and multi-functional technology, applied in membrane, ultrafiltration, membrane technology and other directions, can solve the problems of complicated equipment pipeline, complicated operation and high cost, and achieve the effect of compact equipment structure, convenient user operation and reduced equipment manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

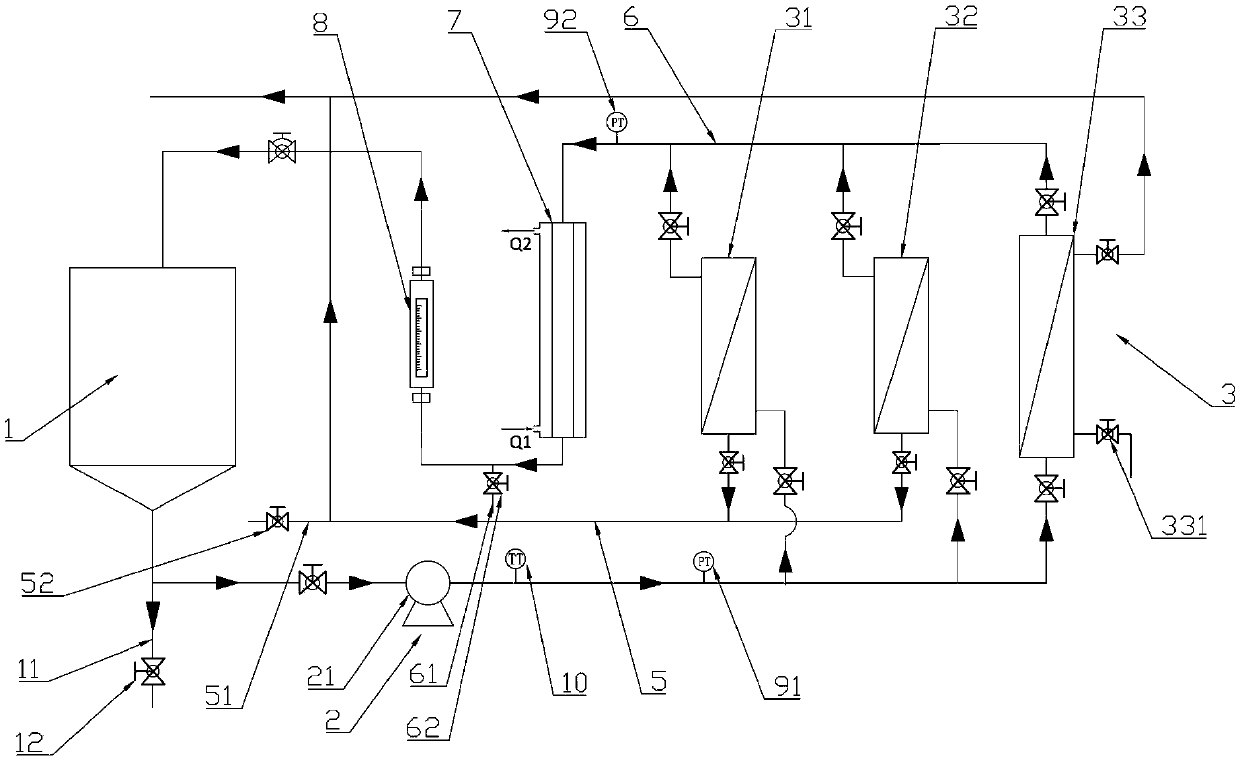

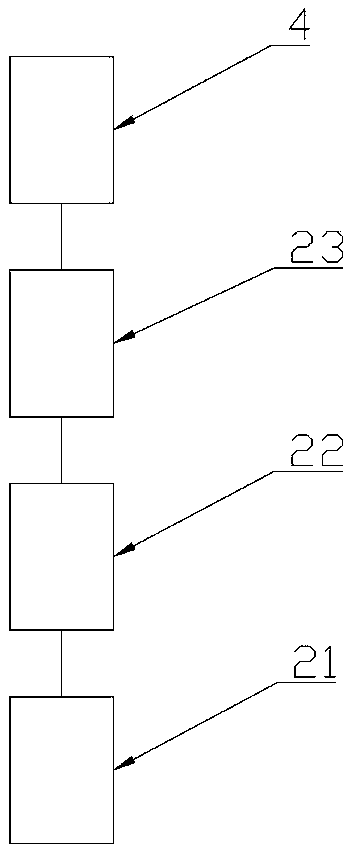

[0022] like figure 1 As shown, a multifunctional membrane filtration system proposed in this embodiment includes a stock solution tank 1, a power module 2, a membrane filtration module 3, a control module 4 and pipelines. The stock solution to be filtered containing different molecular weight components is accommodated in the stock solution tank 1, the stock solution tank 1 is connected with a first emptying pipeline 11, and the first emptying pipeline 11 is provided with a first emptying valve 12, which is opened when the filtration is stopped The first emptying valve 12 can discharge the residual liquid in the raw liquid tank 1 . like figure 2 As shown, the power module 2 includes a centrifugal pump 21, a drive motor 22 and a frequency converter 23. The water inlet of the centrifugal pump 21 is connected to the stock solution tank 1 through a pipeline, and a control valve is arranged on the water inlet pipeline of the centrifugal pump 21. The centrifugal pump 21 and the T...

Embodiment 2

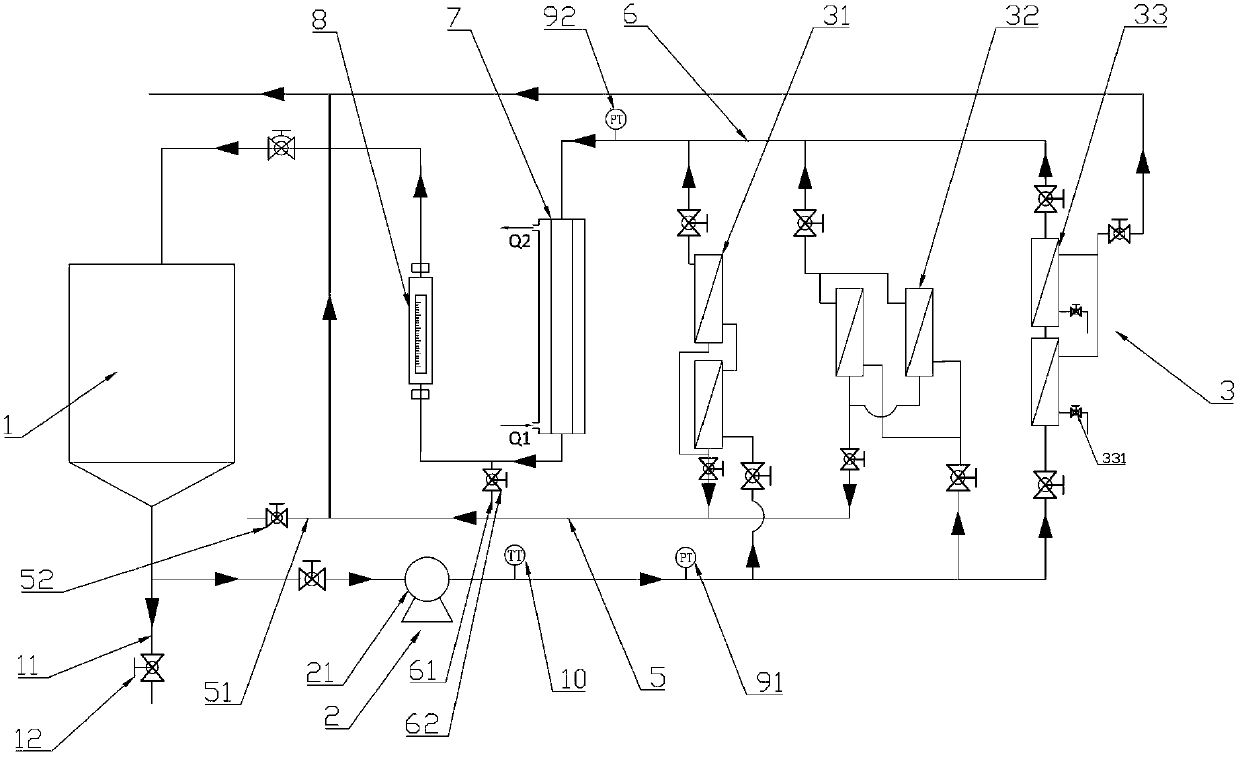

[0027] like image 3As shown, a multifunctional membrane filtration system proposed in this embodiment includes a stock solution tank 1, a power module 2, a membrane filtration module 3, a control module 4 and pipelines. The stock solution to be filtered containing different molecular weight components is accommodated in the stock solution tank 1, the stock solution tank 1 is connected with a first emptying pipeline 11, and the first emptying pipeline 11 is provided with a first emptying valve 12, which is opened when the filtration is stopped The first emptying valve 12 can discharge the residual liquid in the raw liquid tank 1 . The power module 2 includes a centrifugal pump 21, a drive motor 22 and a frequency converter 23. The water inlet of the centrifugal pump 21 is connected to the stock solution tank 1 through a pipeline. A control valve is arranged on the water inlet pipeline of the centrifugal pump 21. The centrifugal pump 21 and the drive motor 22 Electrically conn...

Embodiment 3

[0031] like Figure 4 , a multi-functional membrane filtration system proposed in this example, with the long-term use of the membrane module, when the water yield of the membrane decreases or the use time is long, the membrane needs to be chemically cleaned to remove the pollution on the membrane in time substances to prevent the formation of stubborn scale on the membrane. The prepared acid washing liquid or alkaline washing liquid can be directly added to the raw material 2 to clean the membrane modules online, and the control module 4 controls the opening or closing of the control valve at the water inlet of each membrane module group to select the membrane module to be cleaned The cleaning liquid is returned to the raw material tank 2 through the permeate collection line 5 for circular cleaning, and the rotational speed of the centrifugal pump 21 is controlled by the control module 4 or the first coiled membrane module group 31 and the second coiled membrane module group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com