A kind of jacketed reactor for alkaline hydrolysis of waste tnt

A casing reactor, alkaline hydrolysis technology, applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve the problem that the reactor cannot run continuously and threaten operation Personnel safety, difficult control of reactor temperature, etc., to achieve the effect of facilitating processing, strengthening heat transfer effect, and achieving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings and embodiments.

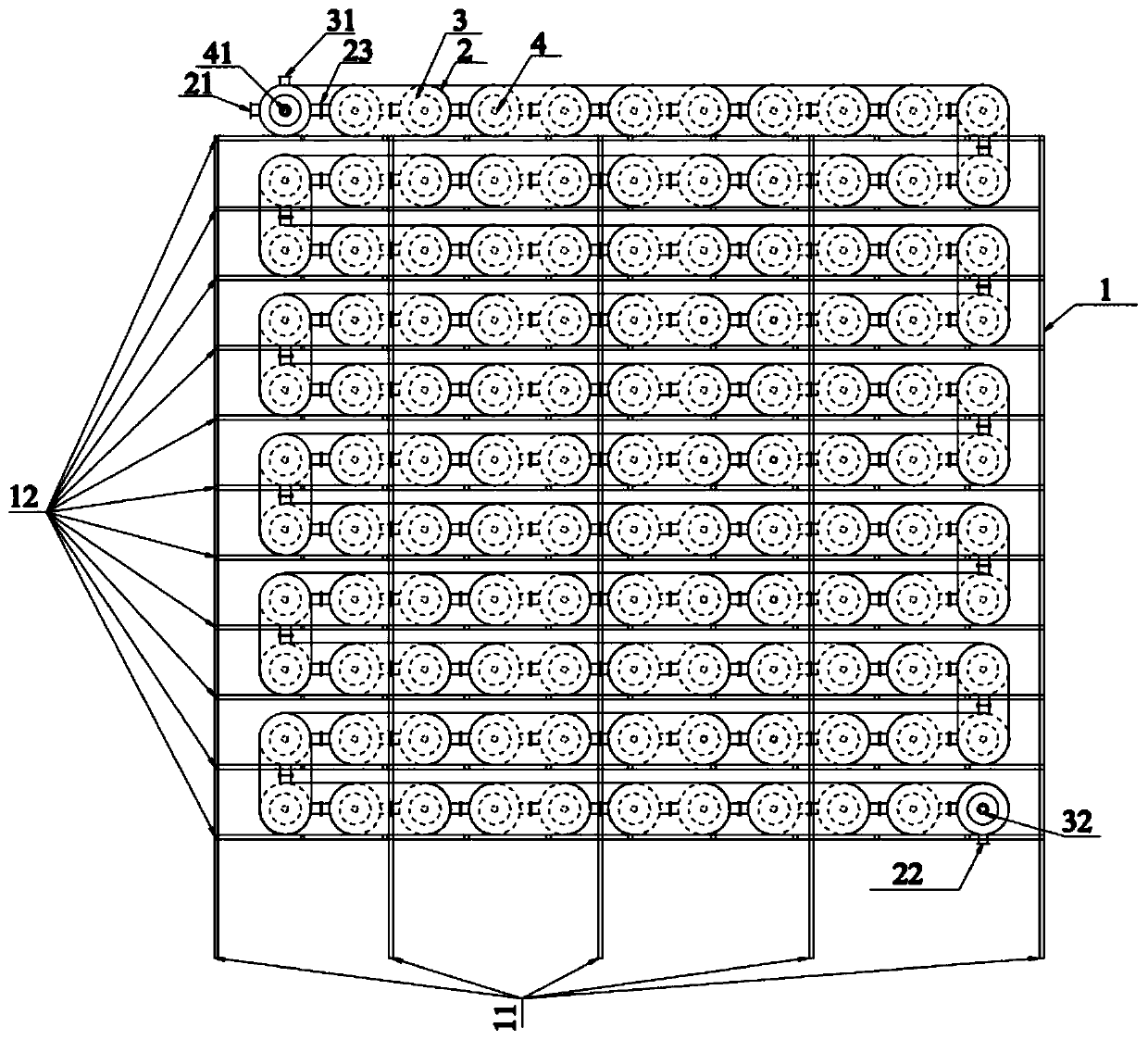

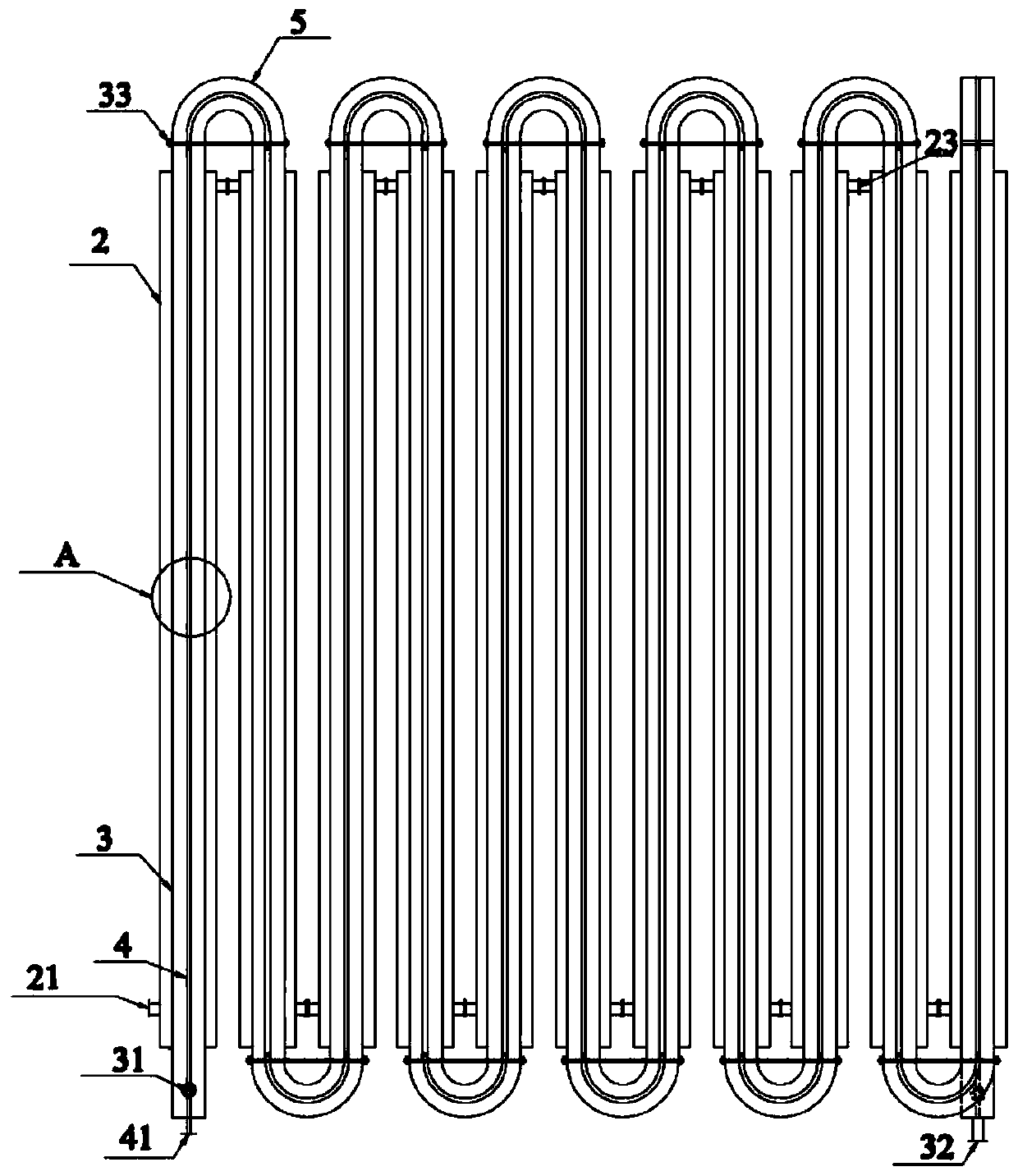

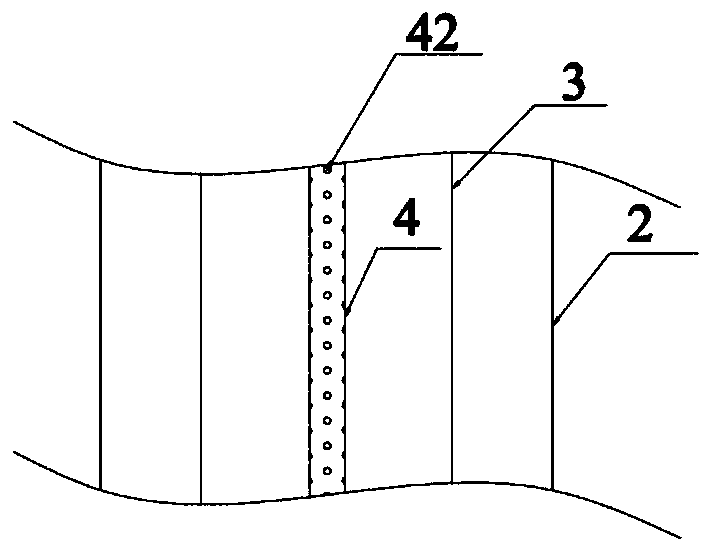

[0029] Such as figure 1 , figure 2 , image 3 As shown, a tube-in-tube reactor for the alkaline hydrolysis of scrapped TNT includes a tube-in-tube reactor installed on a support frame 1. The tube-in-tube reactor includes 121 unit-in-tube reactors, each unit sleeve The tube reactor includes an insulation tube 2, an alkali hydrolysis reaction tube 3 is provided in the insulation tube 2, an alkali hydrolysis reaction tube 3 is nested with an alkali liquid injection tube 4, and the alkali liquid injection tube 4 and the alkali hydrolysis reaction tube 3 are coaxially arranged, The insulation pipe 2 between the two adjacent unit sleeve reactors is connected by an insulation pipe flange 23, and the flow direction of the insulation water is the same as the flow direction of the reaction liquid; the lye injection pipe 4 of the previous unit sleeve reactor and the next unit sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com