Method for enhancing hydrolytic acidification performance of printing and dyeing waste water

A technology for hydrolyzing acidification, printing and dyeing wastewater, applied in chemical instruments and methods, textile industry wastewater treatment, biological water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

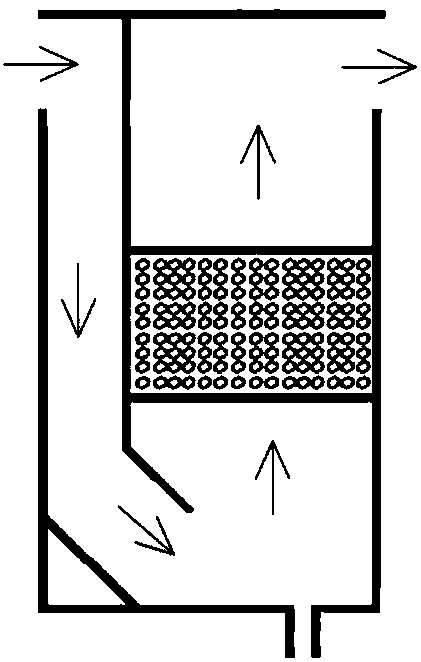

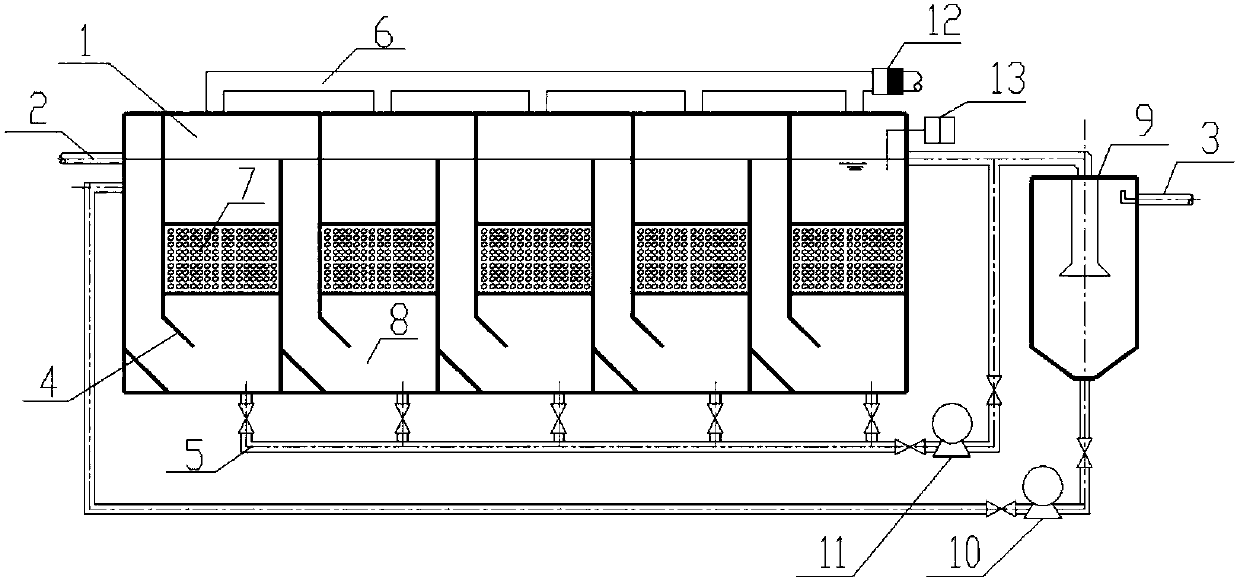

[0032] figure 2 Shown is the schematic diagram of the anaerobic baffle reactor for the treatment of printing and dyeing wastewater in this embodiment, wherein 1, the main body of the reactor; 2, the water inlet; 3, the water outlet; 4, the folding plate between the compartments; 5, the sludge discharge pipe 6. Air duct; 7. Packing layer; 8. Suspended sludge layer; 9. Sedimentation tank; 10. Anaerobic sludge return pump; 11. Sludge pump; 12. Gas flow meter;

[0033] As can be seen from the figure, the specification of the reactor 1 in this embodiment is 10m×3m×2m in length×width×height, and the effective volume is 60m 3 , and made of glass fiber reinforced plastic; including 5 compartments, each compartment includes an upflow chamber and a downflow chamber, the upflow chamber and the downflow chamber are separated by a baffle, and the end of each baffle is A bending angle is provided; as a preference, the width ratio of the upper flow chamber and the lower flow chamber of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com