In-situ compounded carbon quantum dot - titanium dioxide nano materials with titanium dioxide nanotube array, and preparation method thereof

A nanotube array and titanium dioxide technology, which is applied in the field of titanium dioxide nanotube array in-situ composite carbon quantum dots-titania nanomaterials, can solve the problems of reusable performance and photocatalyst recovery problems, and achieve excellent photocatalytic performance, Effect of low cost and improved photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

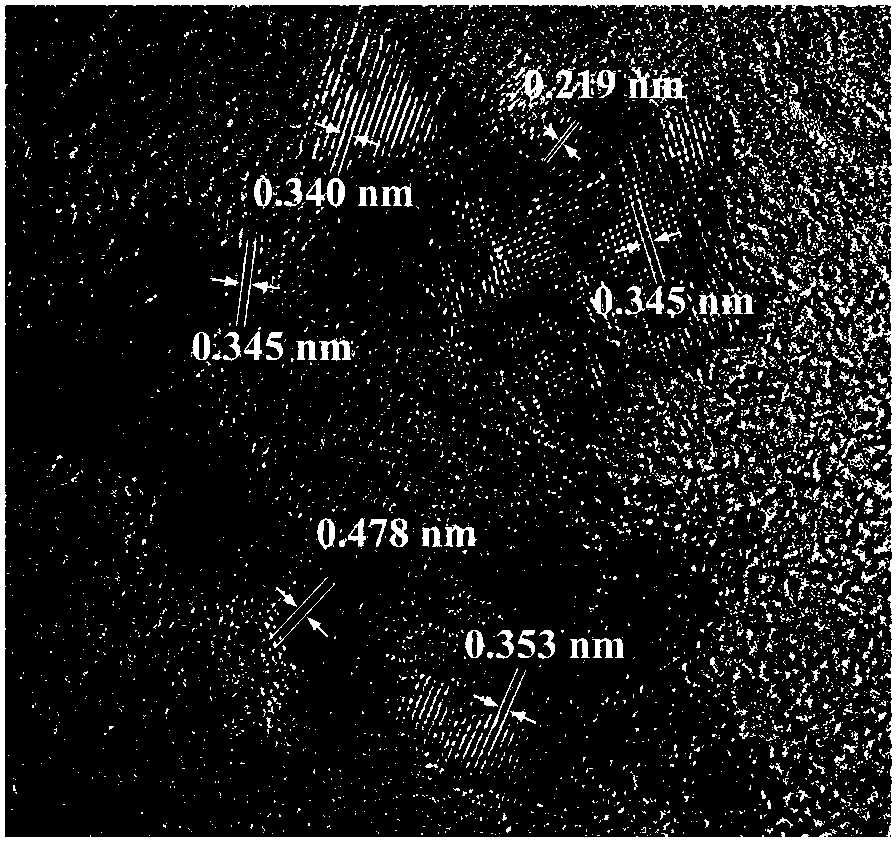

[0026] A method for preparing a titania nanotube array in-situ composite carbon quantum dot-titania nanomaterial, comprising the following steps:

[0027] 1) Titanium foils (purity 99.9%, thickness 0.3mm) were ultrasonically washed with acetone (analytical grade), ethanol (analytical grade) and deionized water for 30 min respectively, and after natural drying, two pieces of titanium foils of the same size were used as The anode and cathode use a mixed aqueous solution of 0.1mol / L NaF and 0.5mol / L NaHSO4 as the electrolyte, apply a voltage of 15V through a DC power supply, and react for 360min by anodic oxidation. After the anode reaction, the titanium foil whose surface is an amorphous titanium dioxide nanotube array is obtained, cleaned with deionized water, air-dried, and set aside.

[0028] 2) Dissolve 1.5g of anhydrous citric acid (purity 99.5%), 0.2ml of triethanolamine (analytical pure) and 10ml of butyl titanate (analytical pure) in 60ml of ethanol (analytical pure), fu...

Embodiment 2

[0038] A method for preparing a titania nanotube array in-situ composite carbon quantum dot-titania nanomaterial, comprising the following steps:

[0039] 1) The titanium foil (purity 99.9%, thickness 0.3mm) was ultrasonically washed with acetone (analytical grade), ethanol (analytical grade) and deionized water for 40 minutes, and after natural drying, a titanium foil of the same size (6cm×2cm) was taken. The foil is used as anode and cathode respectively, and the mixed aqueous solution of NaF with a concentration of 0.1mol / L and NaHSO4 with a concentration of 0.5mol / L is used as an electrolyte, and a voltage of 20V is applied through a DC power supply, and the reaction is performed by anodic oxidation for 180min. After the anode reaction, the titanium foil whose surface is an amorphous titanium dioxide nanotube array is obtained, cleaned with deionized water, air-dried, and set aside.

[0040] 2) Dissolve 1g of anhydrous citric acid (purity 99.5%), 0.2ml triethanolamine (ana...

Embodiment 3

[0044] A method for preparing a titania nanotube array in-situ composite carbon quantum dot-titania nanomaterial, comprising the following steps:

[0045] 1) Titanium foil (purity 99.9%, thickness 0.3mm) was ultrasonically washed with acetone (analytical grade), ethanol (analytical grade) and deionized water for 60 minutes, and after natural drying, a titanium foil of the same size (4cm×1cm) was taken. The foil is used as anode and cathode respectively, and the mixed aqueous solution of NaF with a concentration of 0.1mol / L and NaHSO4 with a concentration of 0.5mol / L is used as an electrolyte, and a voltage of 25V is applied through a DC power supply, and the reaction is performed by anodic oxidation for 360min. After the anode reaction, the titanium foil whose surface is an amorphous titanium dioxide nanotube array is obtained, cleaned with deionized water, air-dried, and set aside.

[0046] 2) Dissolve 2.5g of anhydrous citric acid (purity 99.5%), 0.4ml triethanolamine (analy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com