Water cooled steam turbine unit dead steam waste heat recovery heat supply system

A technology for heating systems and steam turbine units, which is applied in heat recovery systems, steam recovery, steam engine installations, etc., and can solve problems such as excessive back pressure rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A power plant is installed with two 300MW units, and the exhaust steam of one of the steam turbines is recycled.

[0019] The steam turbine unit is water-cooled.

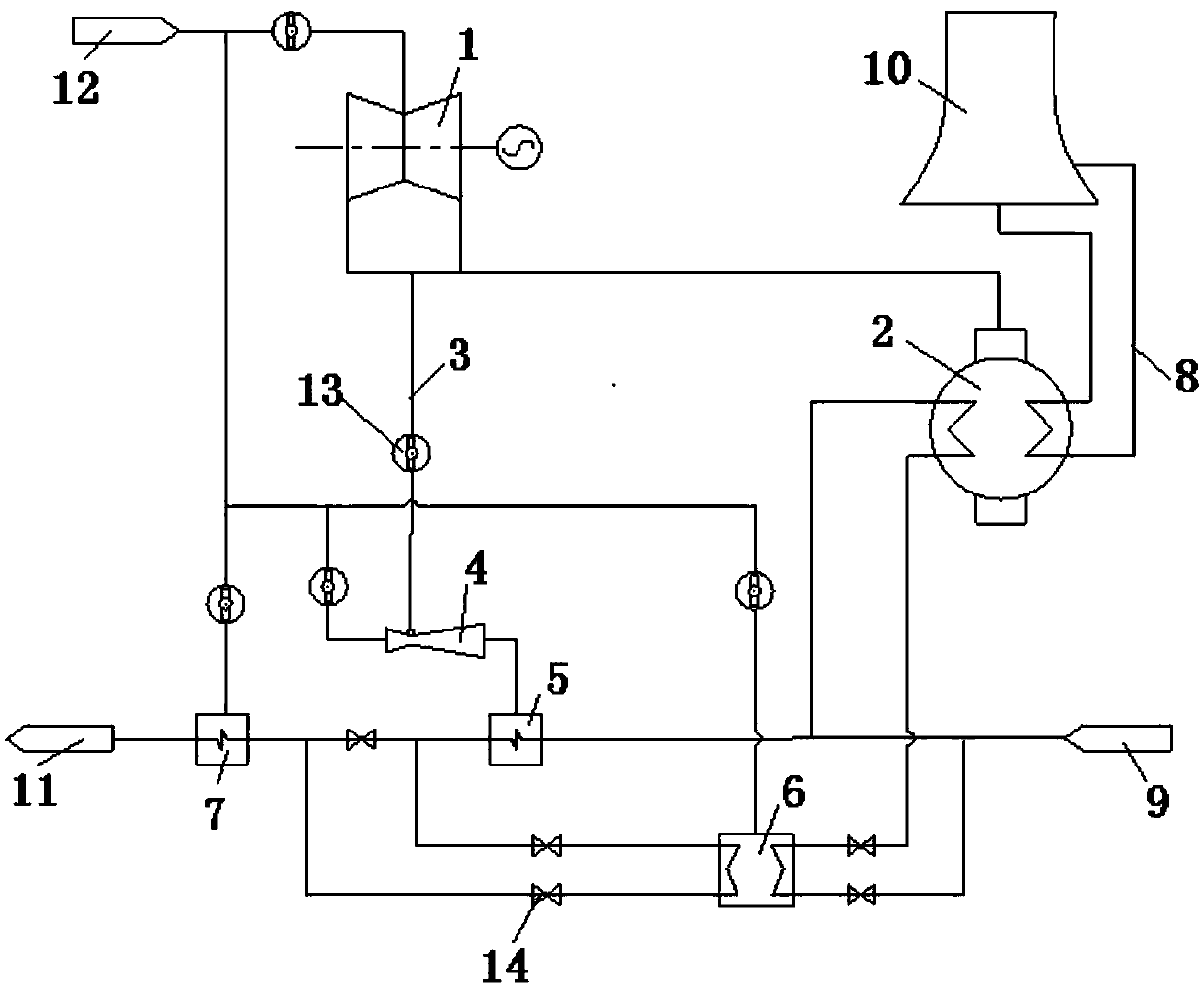

[0020] Thermal power plant exhaust steam recovery heating system, including steam turbine and corresponding condenser, exhaust steam extraction system, steam generator exhaust steam recovery and utilization heating system, absorption or compression heat pump heating system;

[0021] Set the operating back pressure of the steam turbine at 10.5KPa.a. The corresponding saturation temperature is 46.8°C. The exhaust steam is boosted to 21KPa.a by the steam booster (the exhaust temperature of the steam booster is 165°C, and the saturation temperature corresponding to 21KPa.a is 61.1°C). Middle exhaust steam parameter 0.3MPa.a, 233°C.

[0022] Use the exhaust steam extraction system to open holes in the steam turbine condenser or the exhaust steam pipe of the steam turbine to extract the exhaust steam of the stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com