Broadband laser cladding molten pool contour curve and modeling method thereof

A laser cladding and contour curve technology, applied in the field of surface engineering, can solve the problem that the width and area cannot uniquely determine the geometry of the molten pool, and achieve the effect of high accuracy, strong versatility and improved quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

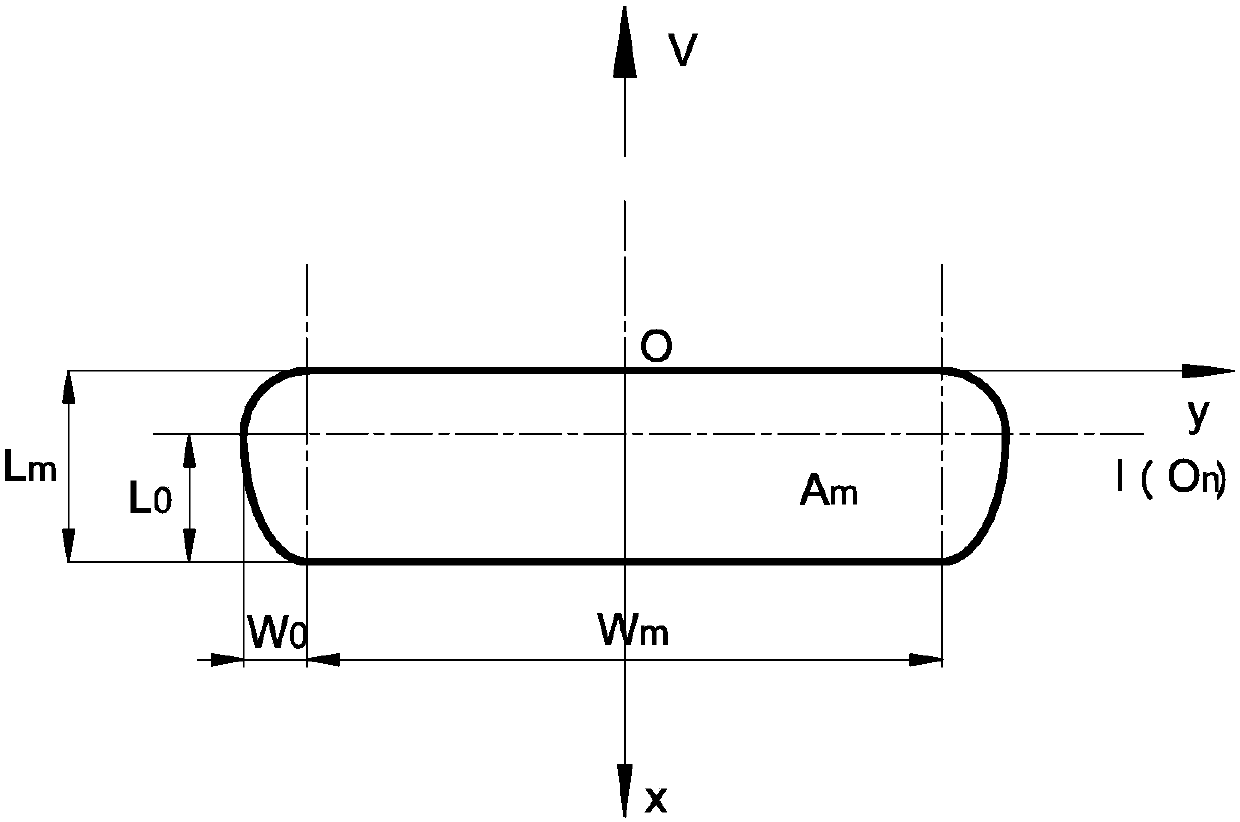

[0028] like figure 1 As shown, a broadband laser cladding melt pool profile curve, on the plane of the broadband laser cladding surface and perpendicular to the laser emission direction, the melt pool profile curve equation is,

[0029]

[0030] Among them, the XOY coordinate system is a Cartesian coordinate system established with the midpoint of the molten pool front as the origin O and the cladding scanning direction as the negative direction of the x-axis. y is the ordinate of the molten pool profile curve in the XOY coordinate system, and x is the horizontal Coordinates, W m is the center width of molten pool, W 0 is the edge width of molten pool, L m is the total length of molten pool in cladding direction, L 0 is the distance from the center of the molten pool to the solidification edge in the cladding direction;

[0031] The maximum valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com