A method for surface texture analysis of carbon fiber composite materials based on gabor transform based on spectrum method

A composite material and surface texture technology, applied in image analysis, image data processing, image enhancement, etc., can solve the problem of the large influence of the three-dimensional measurement value of surface roughness, achieve the compression of the overall dynamic range, eliminate multiplicative noise, increase The effect of contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in detail below in conjunction with specific embodiments.

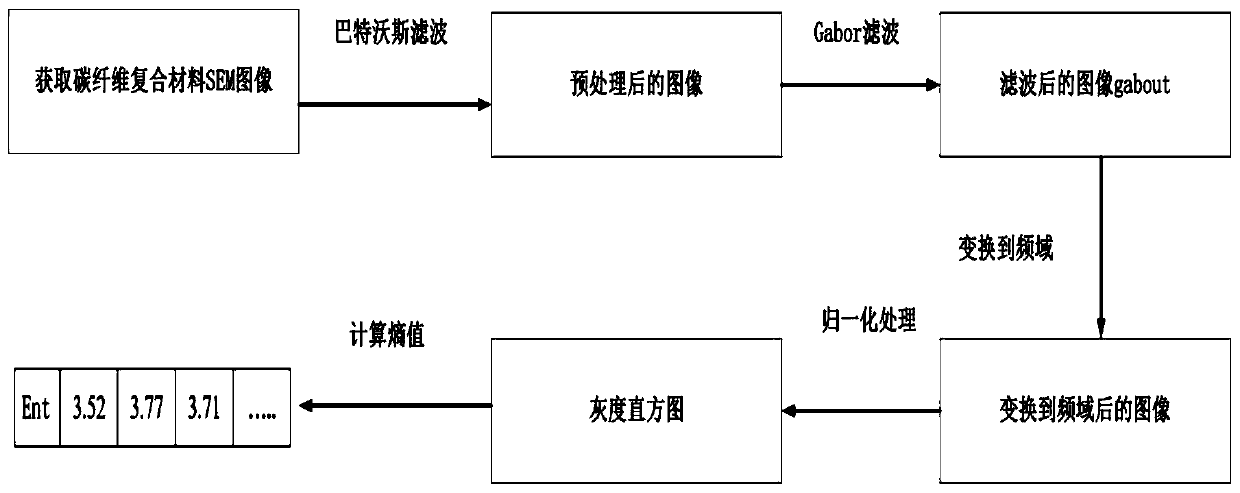

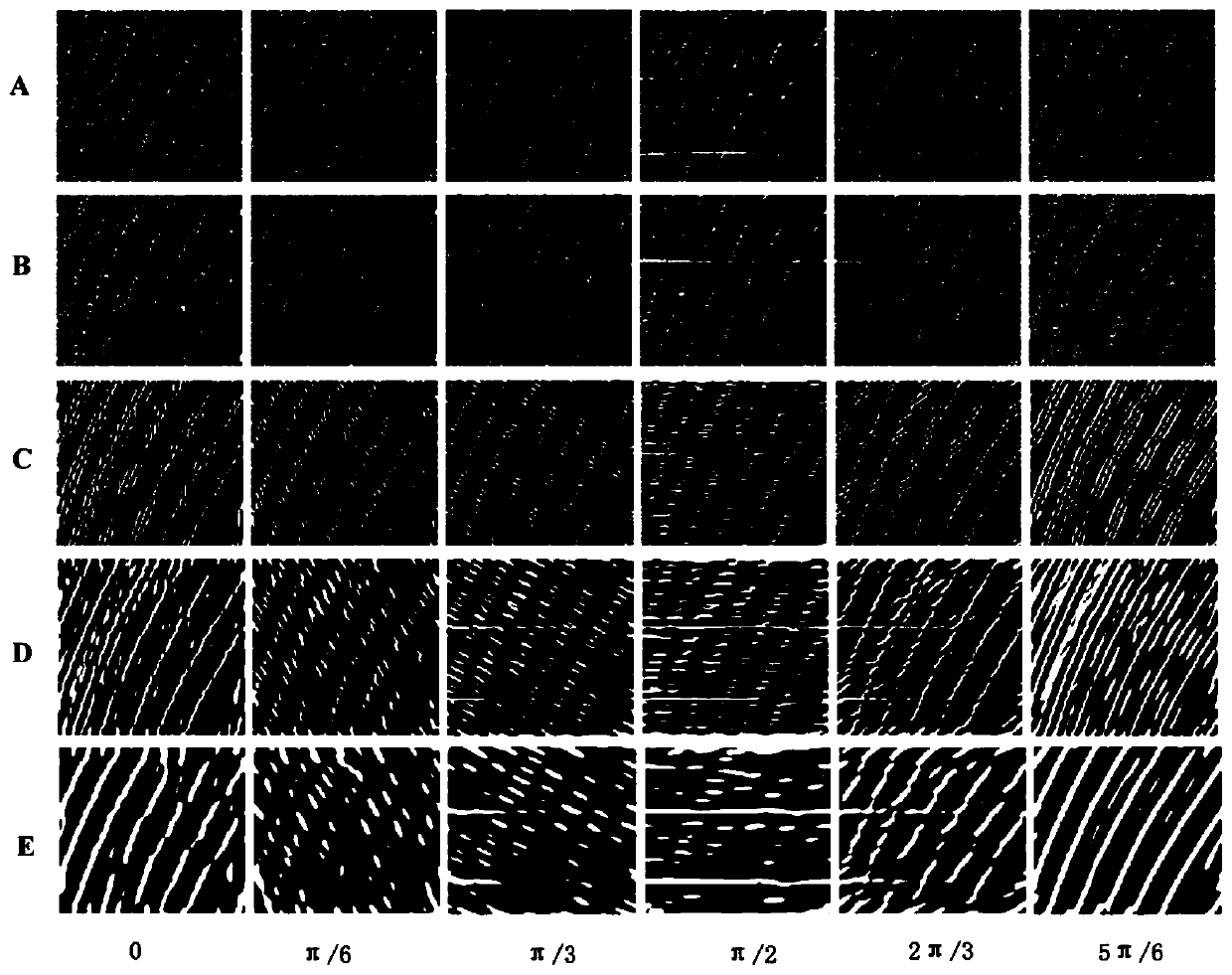

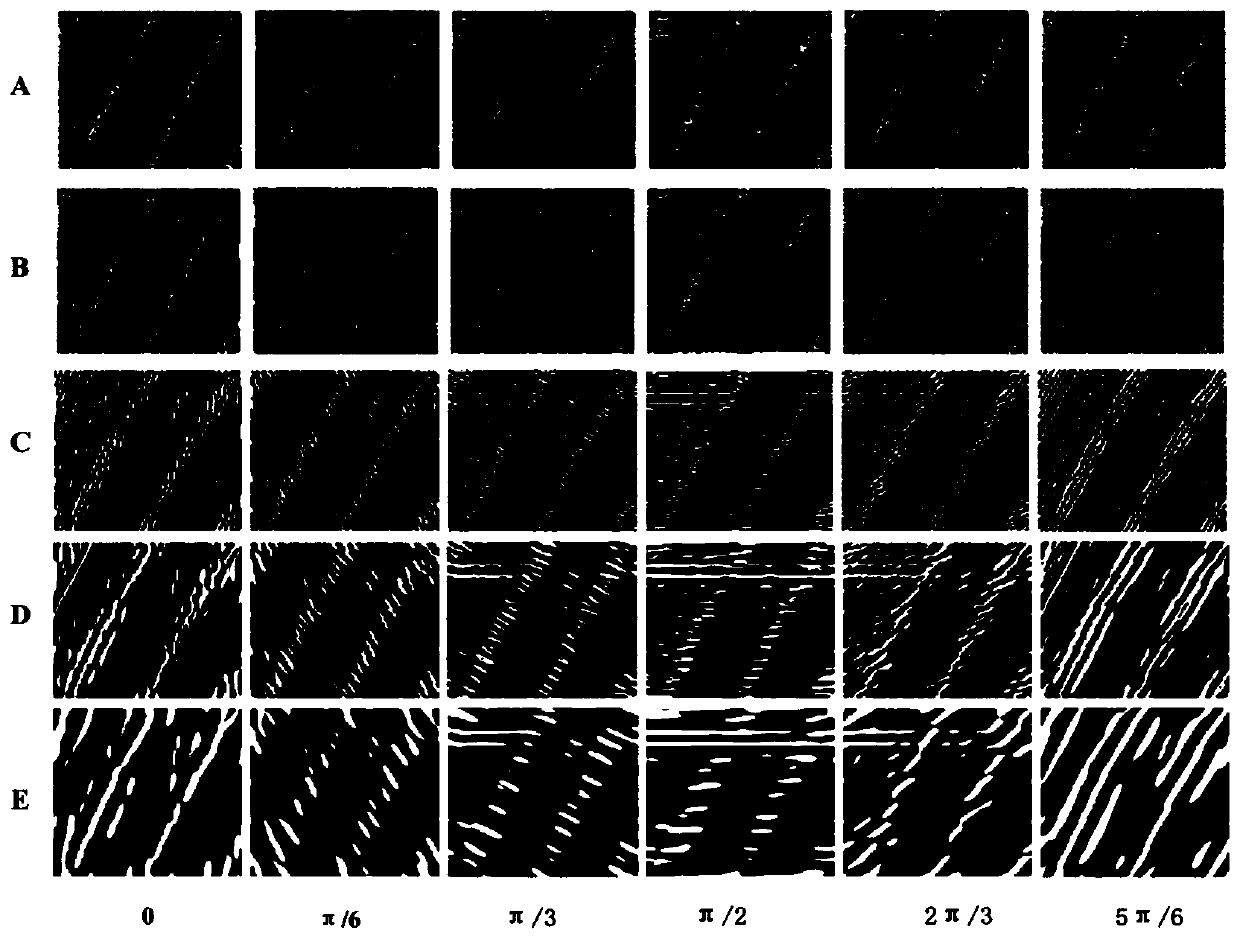

[0064] refer to figure 1 , 2 , 3, 4, 5, 6, a Gabor transformation based on spectrum method realizes the surface texture analysis method of carbon fiber composite material, comprising the following steps:

[0065] Step A, using a scanning electron microscope to obtain SEM images of carbon fiber composite materials, and grouping the images, the process is as follows:

[0066] A1. Group the images according to the magnification, which is divided into 200 times magnification and 500 times magnification;

[0067] A2. Group the images according to the scanning direction of the electron microscope, and divide them into ten scanning directions: 0°, 36°, 72°, 108°, 144°, 180°, 216°, 252°, 288°, and 324°;

[0068] A3. Select a magnification of 200 times and 500 for each scanning direction of the electron microscope as the experimental image.

[0069] Step B, the surface image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com