Single-optical-fiber scanning device

A single optical fiber and device technology, which is applied in the field of imaging optical fiber devices and scanning, can solve the problems of difficult size, size limitation of controllable vibration devices, and difficult assembly process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

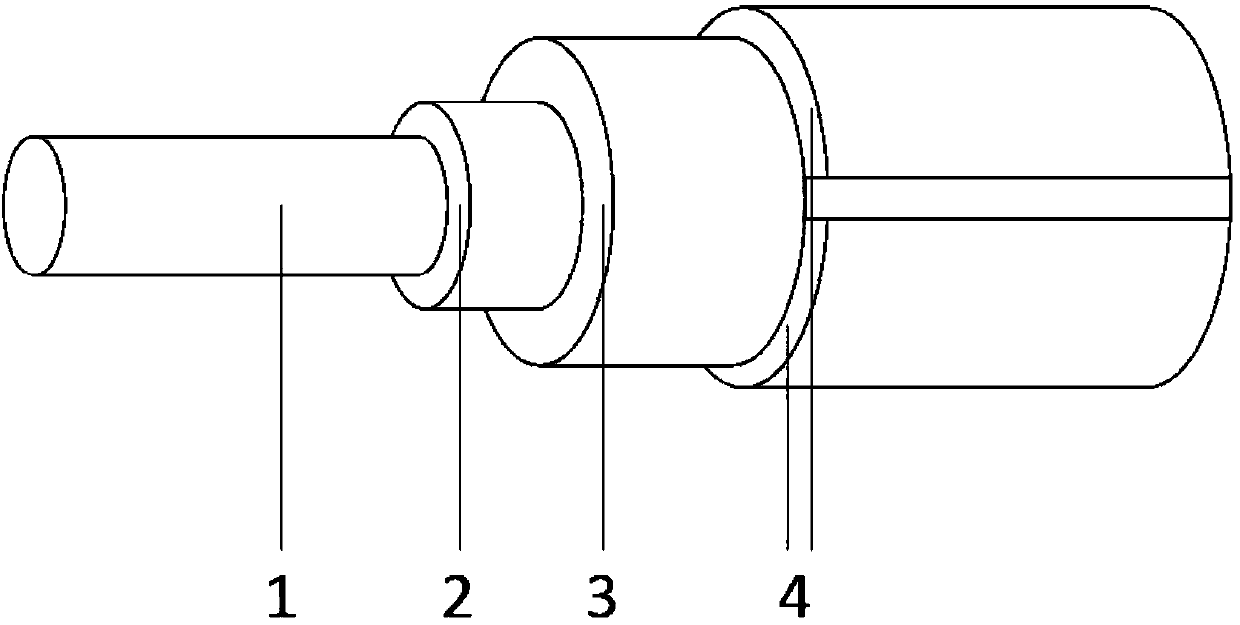

[0016] Attached below figure 2 A vibratable optical fiber described in the present invention and its usage are further described in detail.

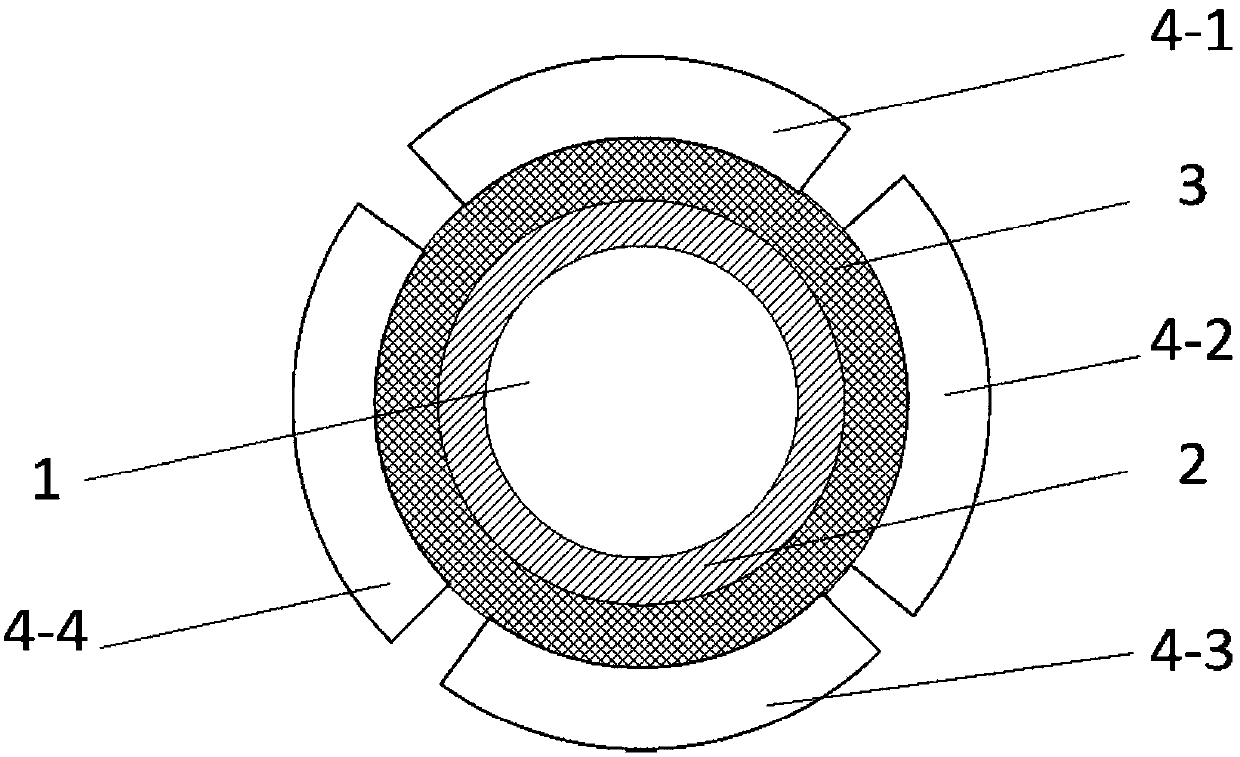

[0017] A kind of vibrating optical fiber, the specific structure is as follows: the optical fiber 1 based on the glass core is used as the output end of the scanning light, the outer layer of the optical fiber 1 is wrapped with a layer of gold electrode 2, and lead zirconate titanate is prepared on the gold electrode 2 For the film 3, 4 equal parts of gold electrodes 4-1, 4-2, 4-3, 4-4 are also prepared on the lead zirconate titanate film 3. The gold electrode 2 , the lead zirconate titanate film 3 and the gold electrode 4 form a structure similar to a sandwich, and the gold electrode 4 is insulated from the gold electrode 2 .

[0018] During operation, 20V sinusoidal voltage and -20V sinusoidal voltage are respectively applied to electrodes 4-1 and 4-3, and opposite electrodes 4-2 and 4-4 are respectively vacant, and gold electrode 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com