Lithium ion battery hazard assessment method

A lithium-ion battery and dangerous technology, applied in the field of quantitative assessment of the safety of the working environment in which the battery is located, can solve problems such as difficulty in giving battery safety specifications, and achieve the effect of scientific fuzzy evaluation methods and accurate safety boundaries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

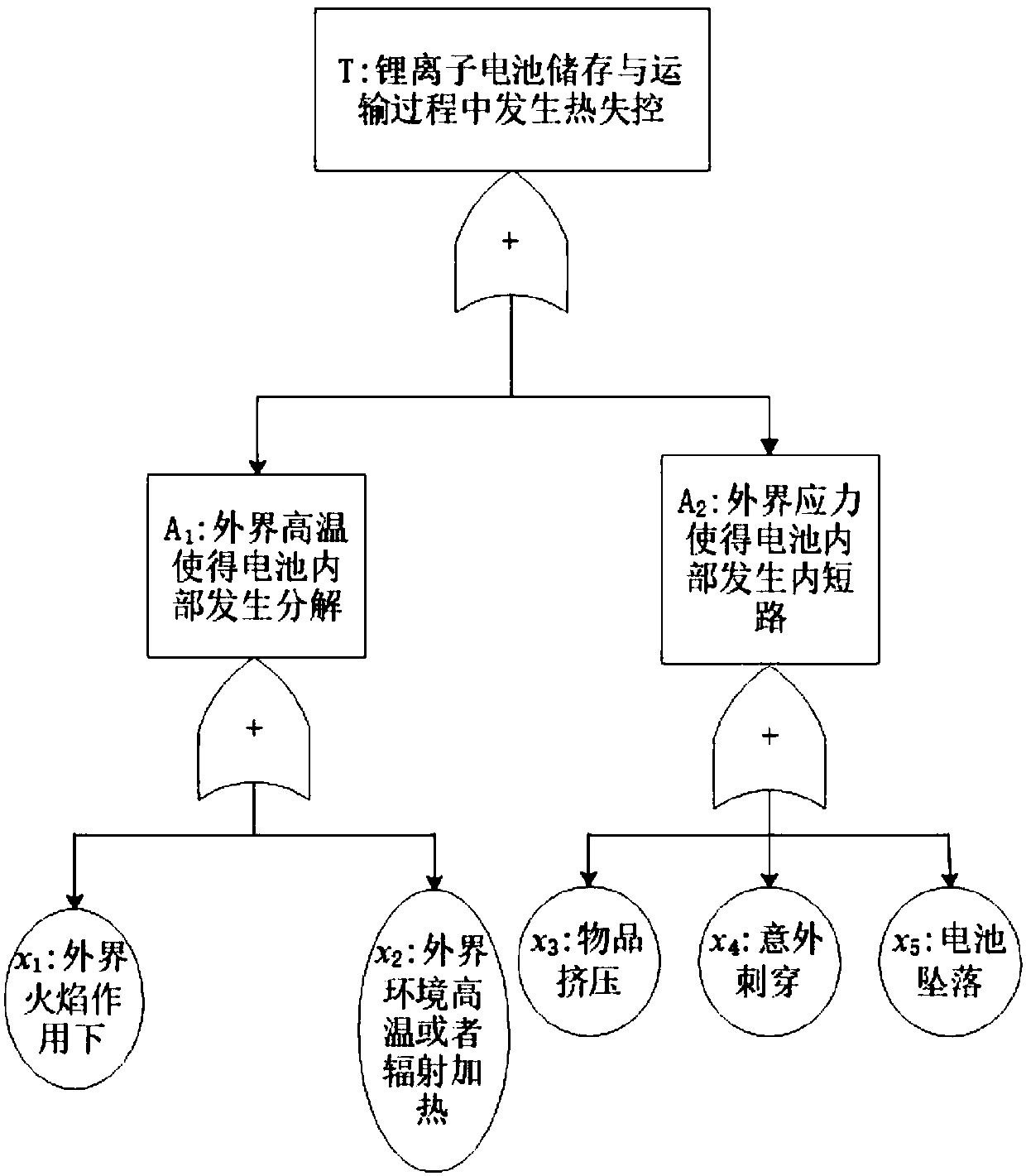

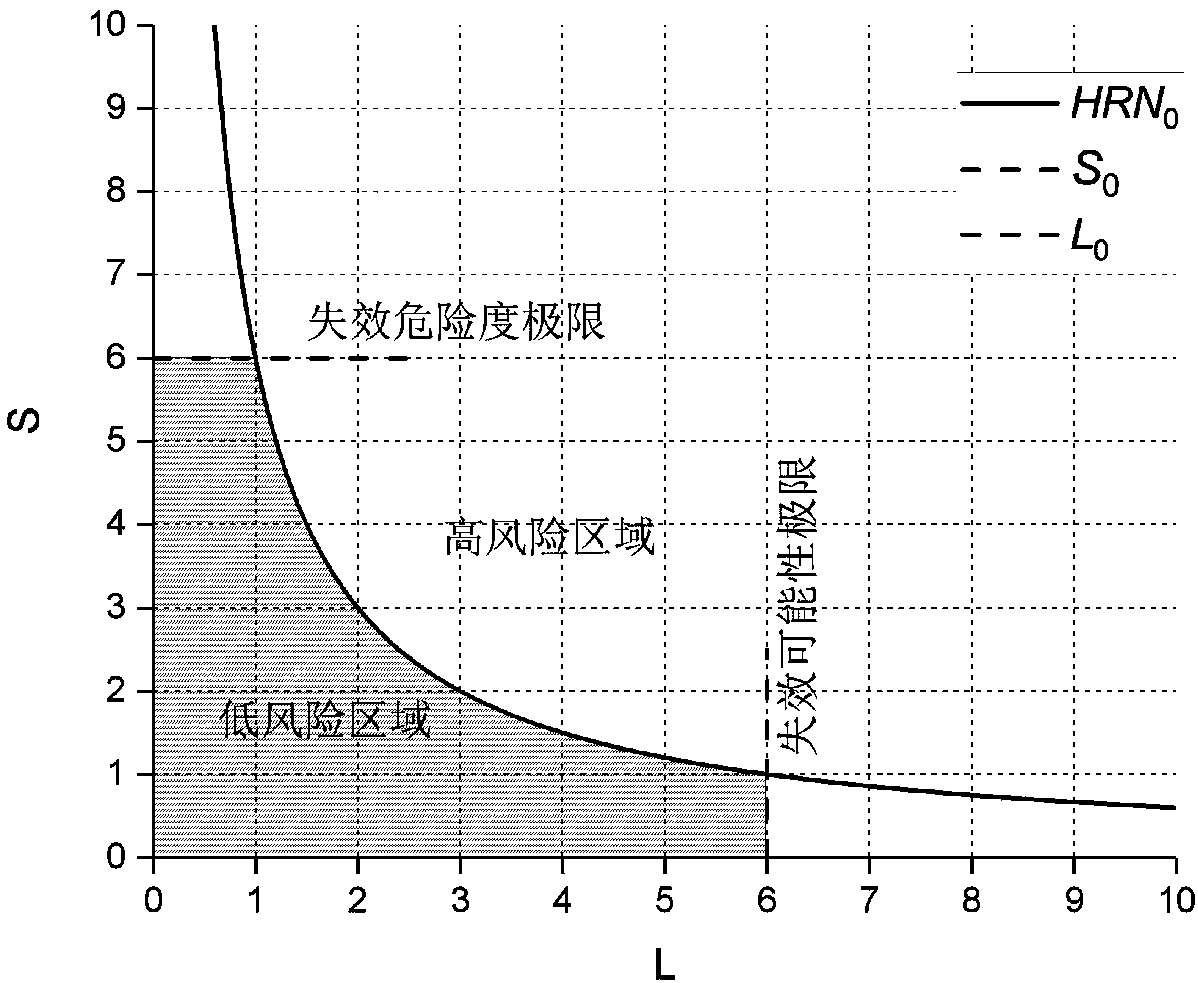

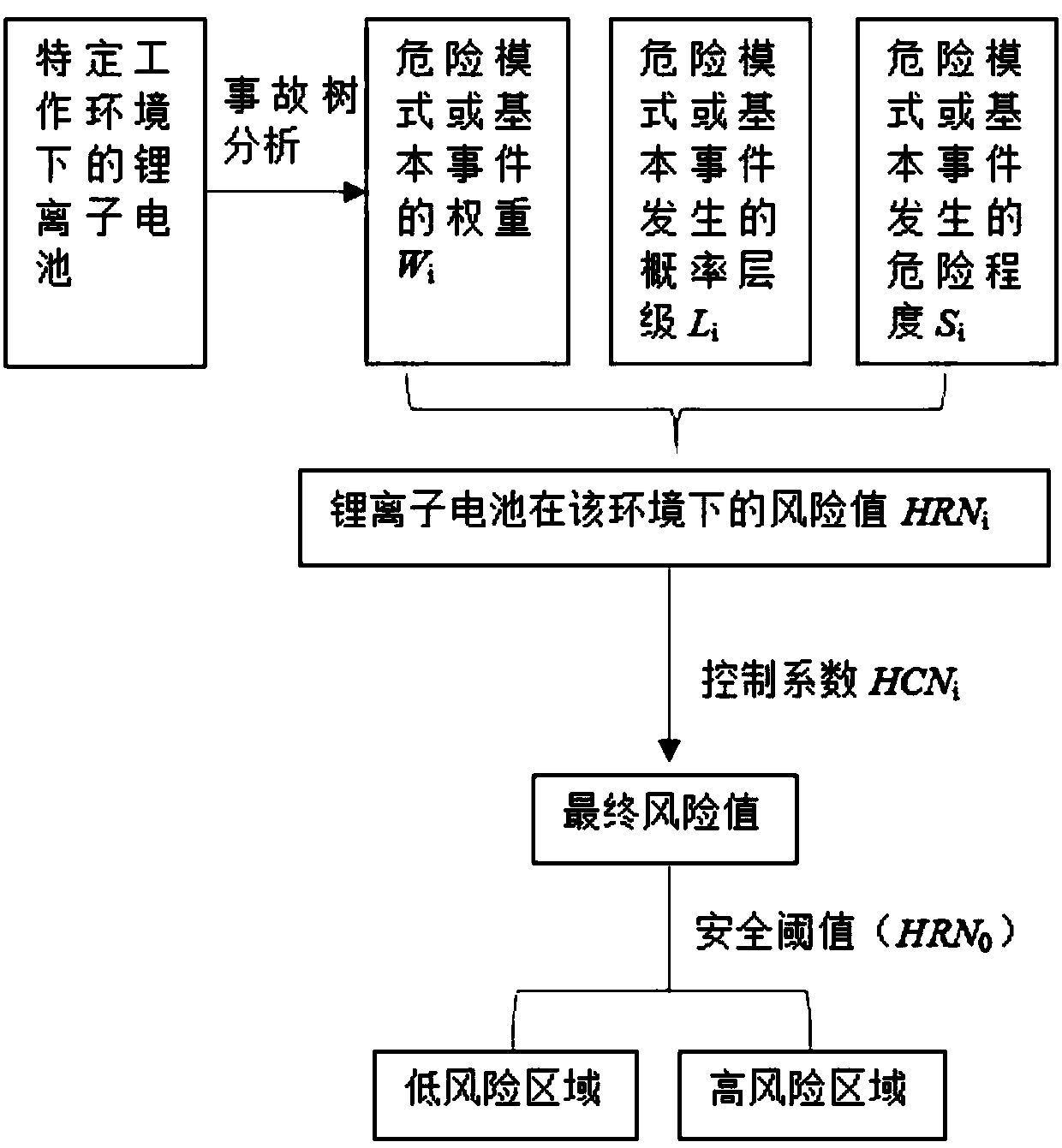

[0059] Implementation case 1: During the storage and transportation of lithium-ion batteries, the risk index of battery failure (S 1 , S 2 ) is assumed to be 5, in the failure mode, the thermal mode weight (W 1 ) accounted for 40%, while the mechanical mode (W 2 ) accounted for 60%. The degree of possibility of occurrence of thermal failure mode (L 1 ) is assumed to be 6, the degree of possibility of occurrence of mechanical failure mode (L 2 ) is assumed to be 5. At this time, the risk index of battery storage and transportation is:

[0060] HRN=L 1 ×S 1 ×W 1 +L 2 ×S 2 ×W 2 =27 (9)

[0061] If a temperature sensor is added to the protection system to detect the temperature, and a thermal management system is used to prevent the battery from overheating due to external heat, the risk control index (HCN 1 ) is assumed to be 0.6, and then a series of shock absorbing devices are used to reduce the impact of mechanical failure during battery storage and transportation...

Embodiment example 2

[0063] Implementation case 2: During the operation of pure electric vehicle batteries, the main failure modes that lead to battery failure are thermal mode (high temperature, flame), electrical mode (overcharge, overdischarge, internal short circuit), mechanical mode (acupuncture, extrusion, collision). These three modes cause the risk index of battery failure to be S1=7, S2=6, S3=5 respectively, and the corresponding weights are W 1 =30%, W 2 =60%, W 3 = 10%. The degree of possibility of occurrence of thermal failure mode (L 1 ) is assumed to be 4, the degree of possibility of occurrence of electrical failure mode (L 2 ) is assumed to be 6, the degree of possibility of occurrence of mechanical failure mode (L 3 ) is assumed to be 5. At this time, the risk index when the electric vehicle is running is:

[0064] HRN=L 1 ×S 1 ×W 1 +L 2 ×S 2 ×W 2 +L 3 ×S 3 ×W 3 =32.5 (11)

[0065] In the electric vehicle system, it is often necessary to install many protective de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com