Novel thermistor array chip and preparation method of same

A thermistor, a new type of technology, applied in the field of new thermistor chip and its preparation, can solve the problems of difficult to reduce the size of the application module, occupy a large space, unfavorable integration, etc., to improve reliability and consistency, Ease of implementation, improved installation efficiency and installation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

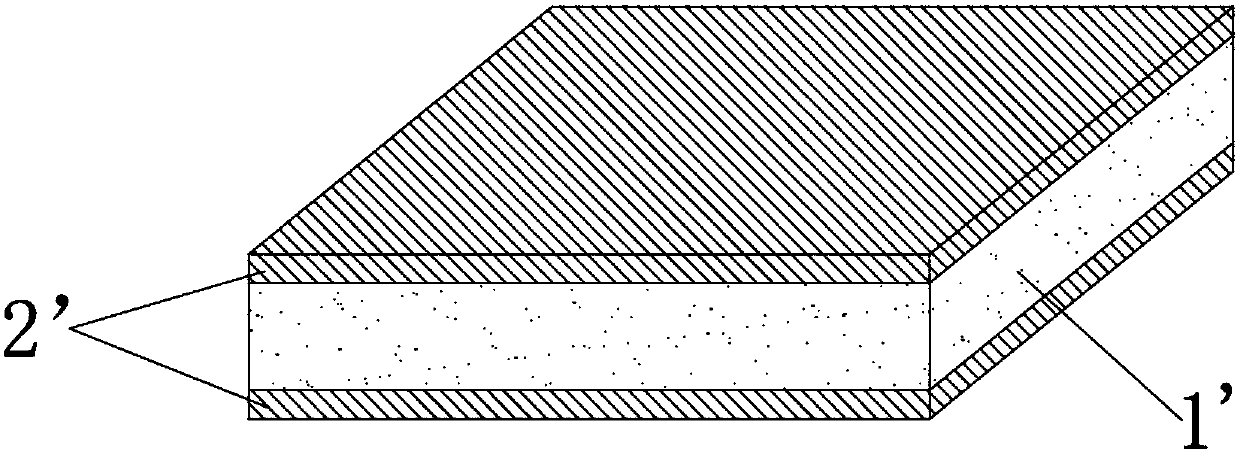

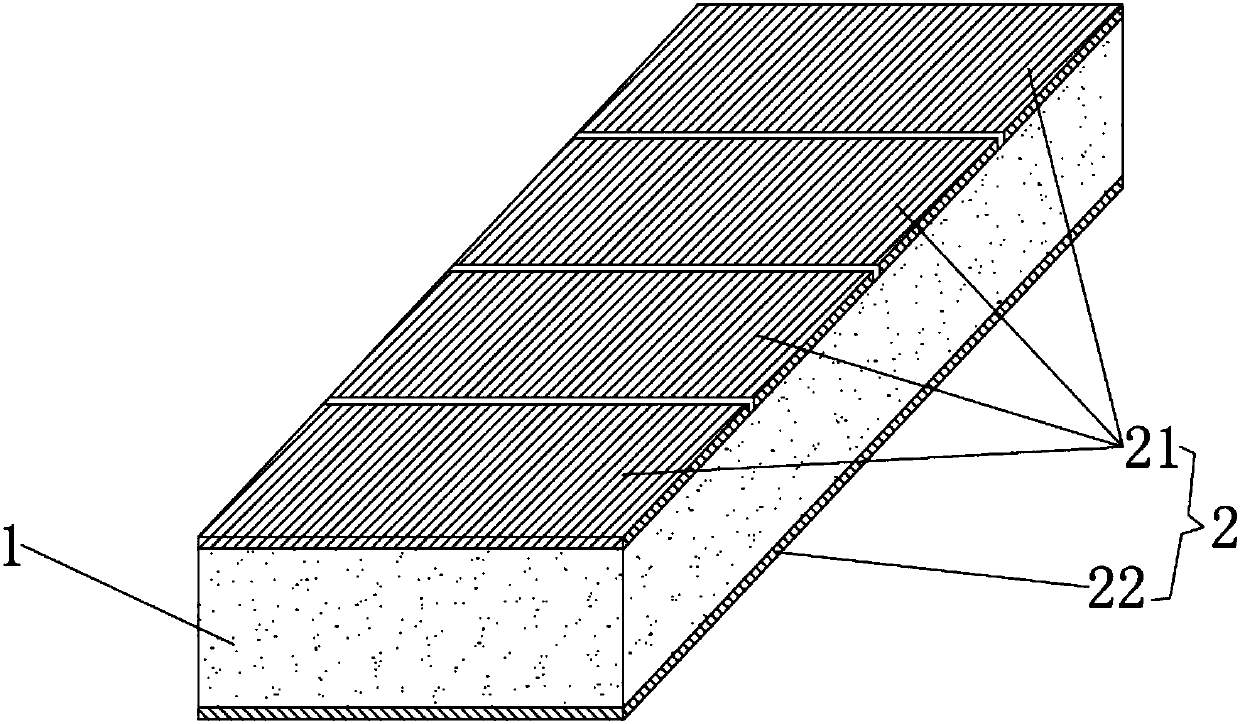

[0033] see image 3 , which is a structural diagram of the novel thermistor array chip of the present invention. The novel thermistor array chip includes a thermal ceramic chip 1 and a metal electrode 2 arranged on the surface of the thermal ceramic chip 1 .

[0034] Specifically, the heat-sensitive tile 1 is rectangular, with a thickness of 200-2000 μm, and its material is NTC heat-sensitive ceramic material.

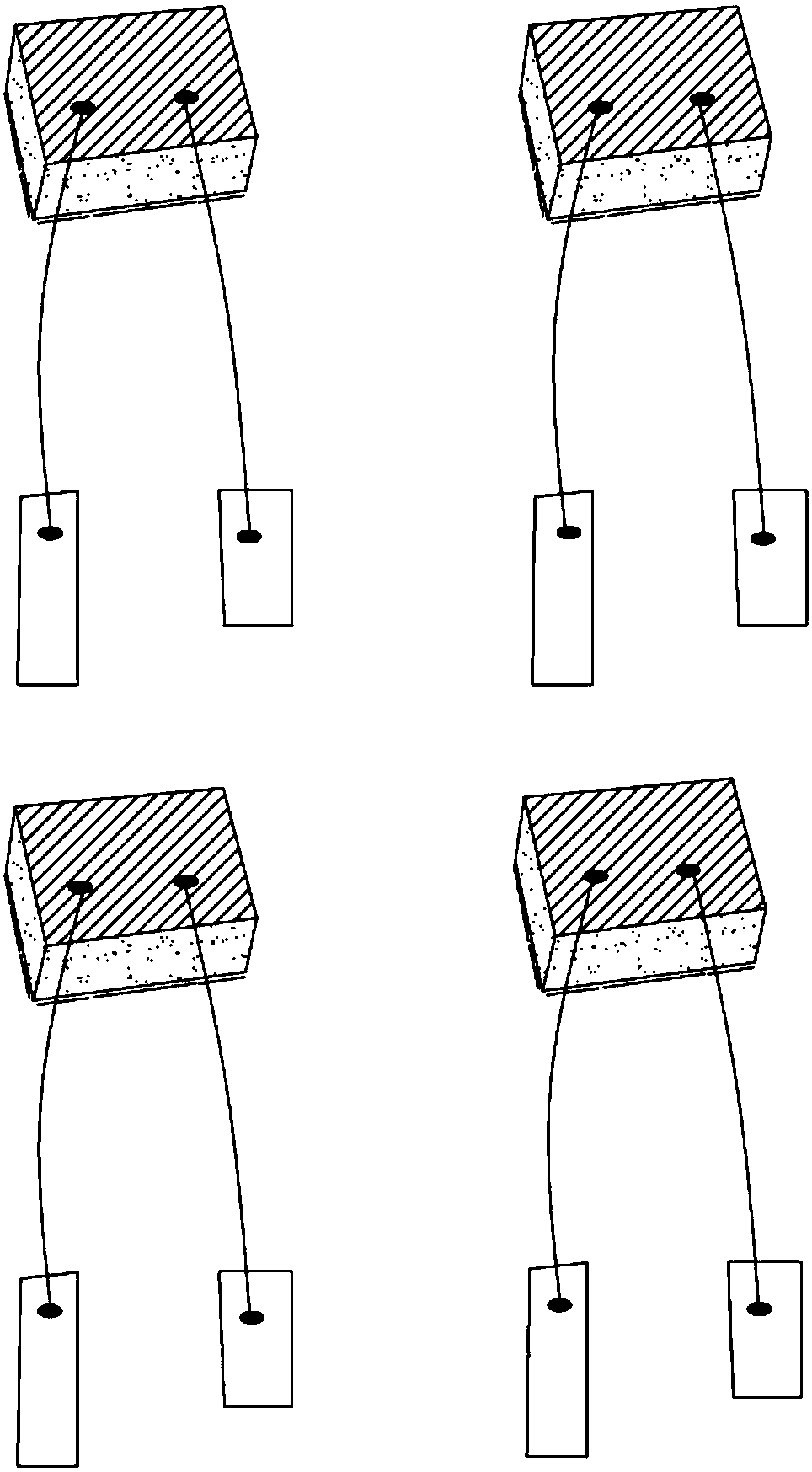

[0035] The metal electrode 2 includes at least two top electrodes 21 , preferably four top electrodes 21 in total, and one bottom electrode 22 .

[0036] The four top electrodes 21 are arranged side by side and at intervals on the upper surface of the heat-sensitive ceramic chip 1, each top electrode 21 is a rectangular layered structure, and its pair of sides is respectively connected to two sides of the heat-sensitive ceramic chip 1. The long sides are flush.

[0037] The bottom electrode 22 is a layered structure, which completely covers the lower surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com