Circular lifting type solar energy charging pile

A solar energy, lift-type technology, applied in current collectors, electric vehicles, electrical components, etc., can solve problems such as simple structure, and achieve the effects of convenient locking and unlocking operations, stable and precise connection and coordination, and simple overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

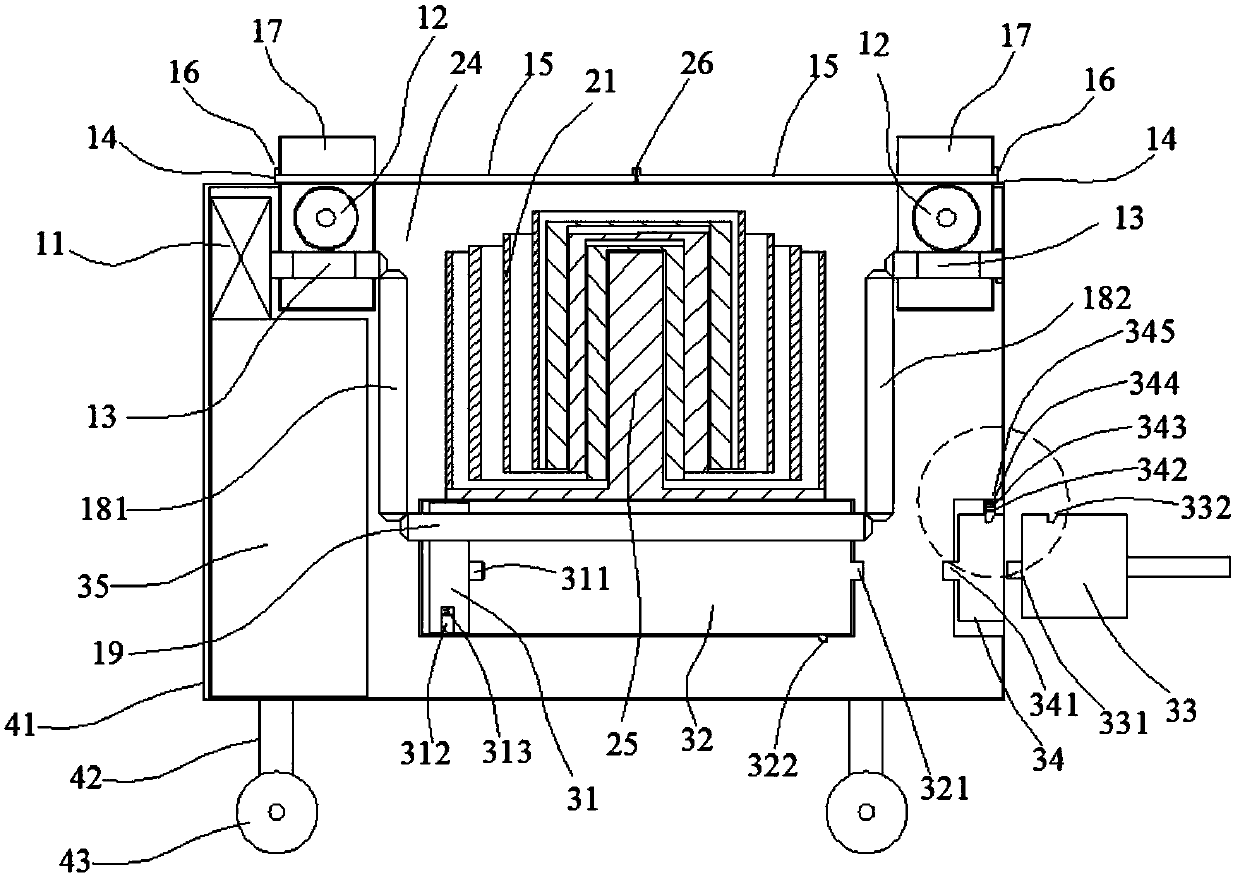

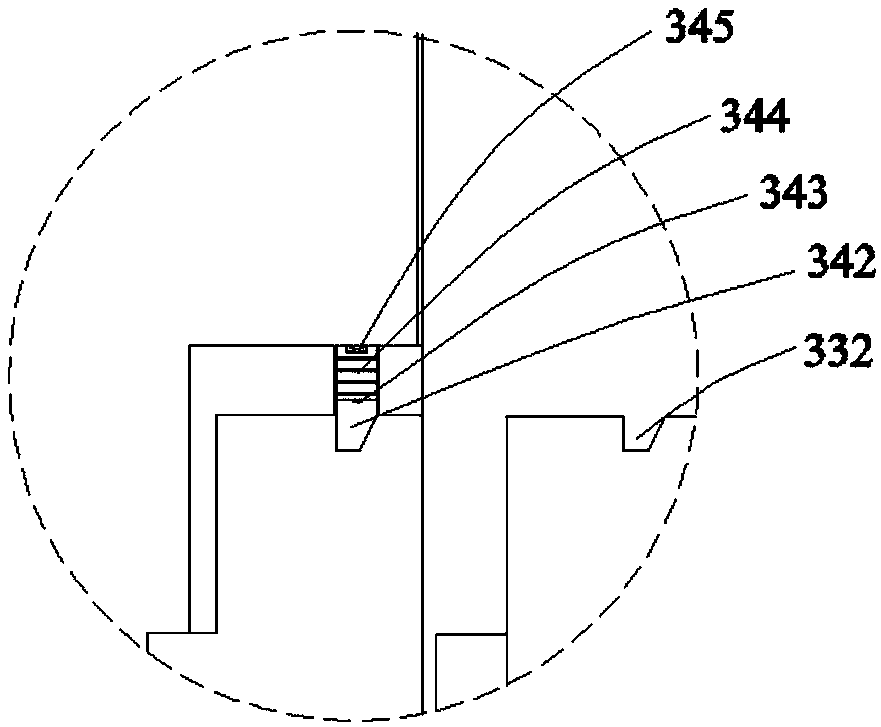

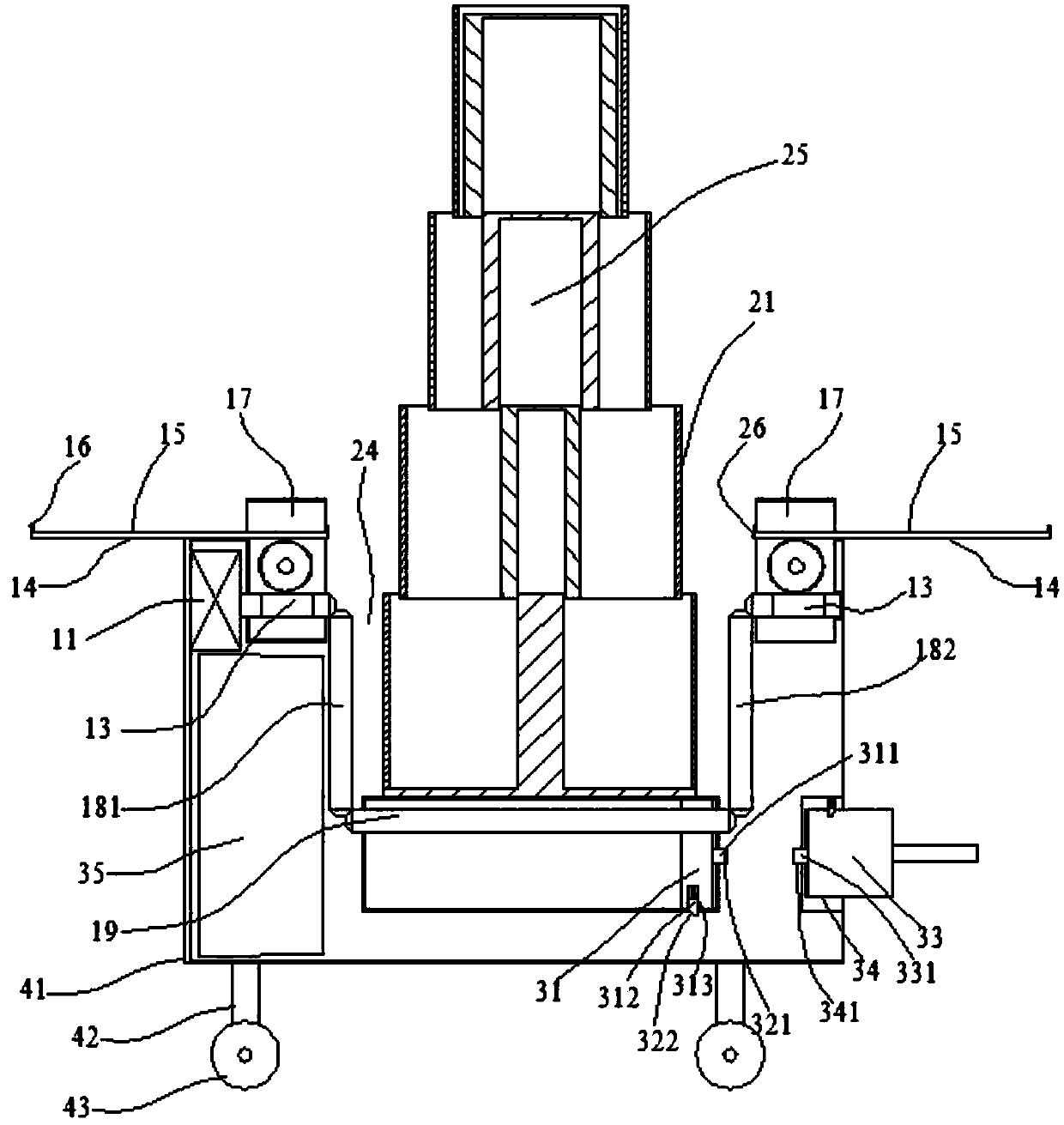

[0033] Such as Figure 1-4 As mentioned above, this embodiment provides a circular lifting solar charging pile, which includes a transmission system 1 located inside the housing 41, a solar panel lifting system 2 and an electric power system 3; the transmission system 1 includes two symmetrical worms 13. One end of the left worm 13 is driven and connected to the motor 11, and the other end is connected to the upper end of the vertical linkage rod 181 through the bevel gear drive, and the lower end of the linkage rod 181 is connected to the left end of the horizontal screw rod 19 through the bevel gear drive, and the right end of the screw rod 19 passes through the cone The tooth drive is connected to the lower end of the linkage rod 182, and the upper end of the linkage rod 182 is connected to the right worm 13 through a bevel gear drive; The plate 21 stretches out with the rise of the hydraulic cylinder 25 and is distributed in steps. The lower end of the outer circumference ...

Embodiment 2

[0035] Such as Figure 1-4As mentioned above, this embodiment provides a circular lifting solar charging pile, which includes a transmission system 1 located inside the housing 41, a solar panel lifting system 2 and an electric power system 3; the transmission system 1 includes two symmetrical worms 13. One end of the left worm 13 is driven and connected to the motor 11, and the other end is connected to the upper end of the vertical linkage rod 181 through the bevel gear drive, and the lower end of the linkage rod 181 is connected to the left end of the horizontal screw rod 19 through the bevel gear drive, and the right end of the screw rod 19 passes through the cone The tooth drive is connected to the lower end of the linkage rod 182, and the upper end of the linkage rod 182 is connected to the right worm 13 through a bevel gear drive. The top of the worm 13 is driven to connect to the worm gear 12, and the top of the worm gear 12 is driven to connect to the rack 14 in the ho...

Embodiment 3

[0037] Such as Figure 1-4 As mentioned above, this embodiment provides a circular lifting solar charging pile, which includes a transmission system 1 located inside the housing 41, a solar panel lifting system 2 and an electric power system 3; the transmission system 1 includes two symmetrical worms 13. One end of the left worm 13 is driven and connected to the motor 11, and the other end is connected to the upper end of the vertical linkage rod 181 through the bevel gear drive, and the lower end of the linkage rod 181 is connected to the left end of the horizontal screw rod 19 through the bevel gear drive, and the right end of the screw rod 19 passes through the cone The lower end of the linkage rod 182 is connected to the tooth drive, and the upper end of the linkage rod 182 is connected to the right worm 13 through a bevel gear drive. , two protective plates 15 are combined to cover the cavity 24, the left and right ends of the protective plate 15 are provided with baffles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com