Multi-station automatic grafting device

An automatic grafting, multi-station technology, applied in grafting and other directions, can solve the problems of unsecured survival rate, easy damage to plants, strong limitations, etc., so as to achieve the goal of not easily harming plants, avoiding manual grafting operations, and eliminating friction. squeezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiment of the present invention will be explained in detail below in conjunction with the accompanying drawings. The examples given are only for the purpose of illustration, and cannot be interpreted as limiting the present invention. The accompanying drawings are only for reference and description, and do not constitute the scope of patent protection of the present invention. limitations, since many changes may be made in the invention without departing from the spirit and scope of the invention.

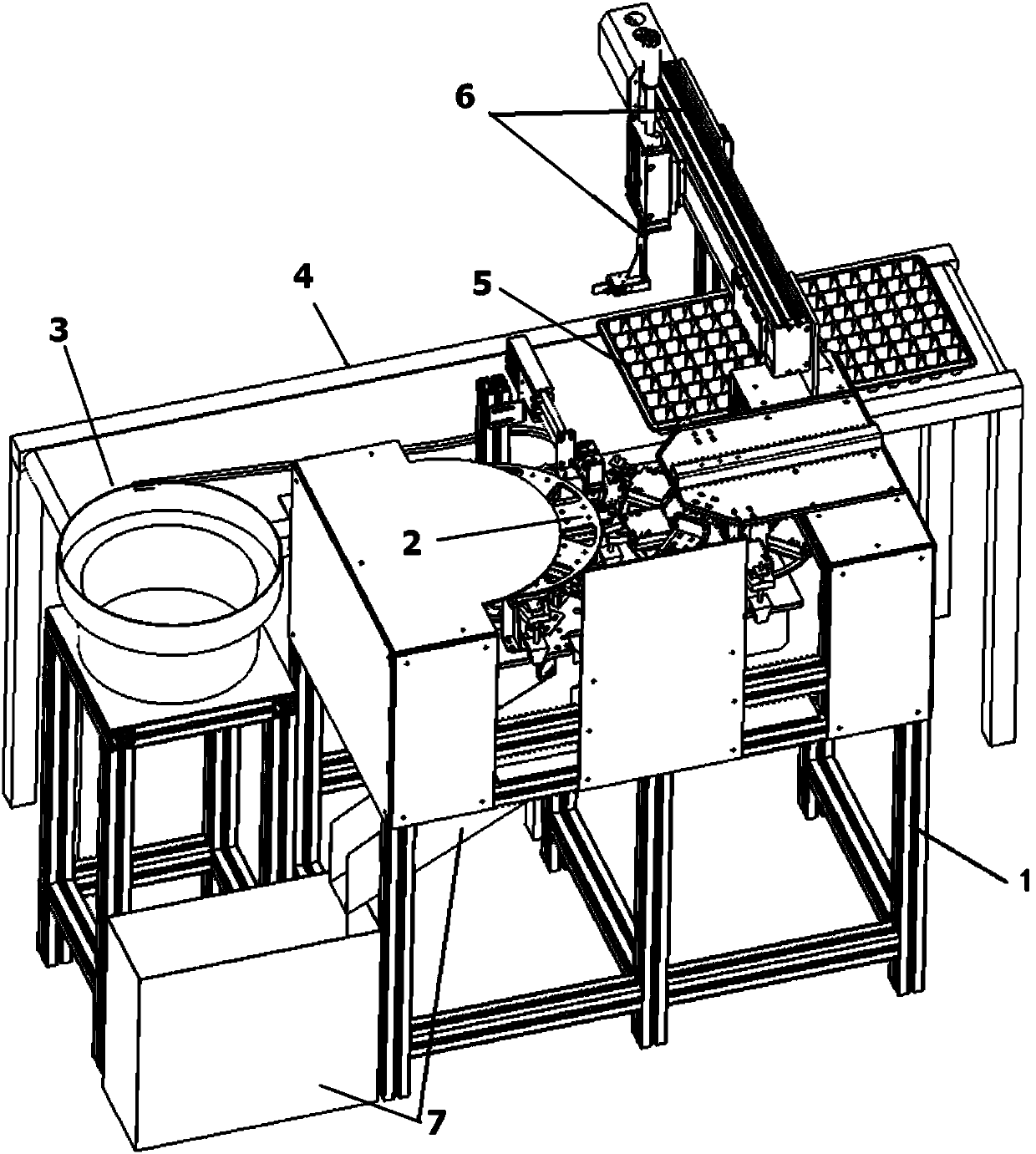

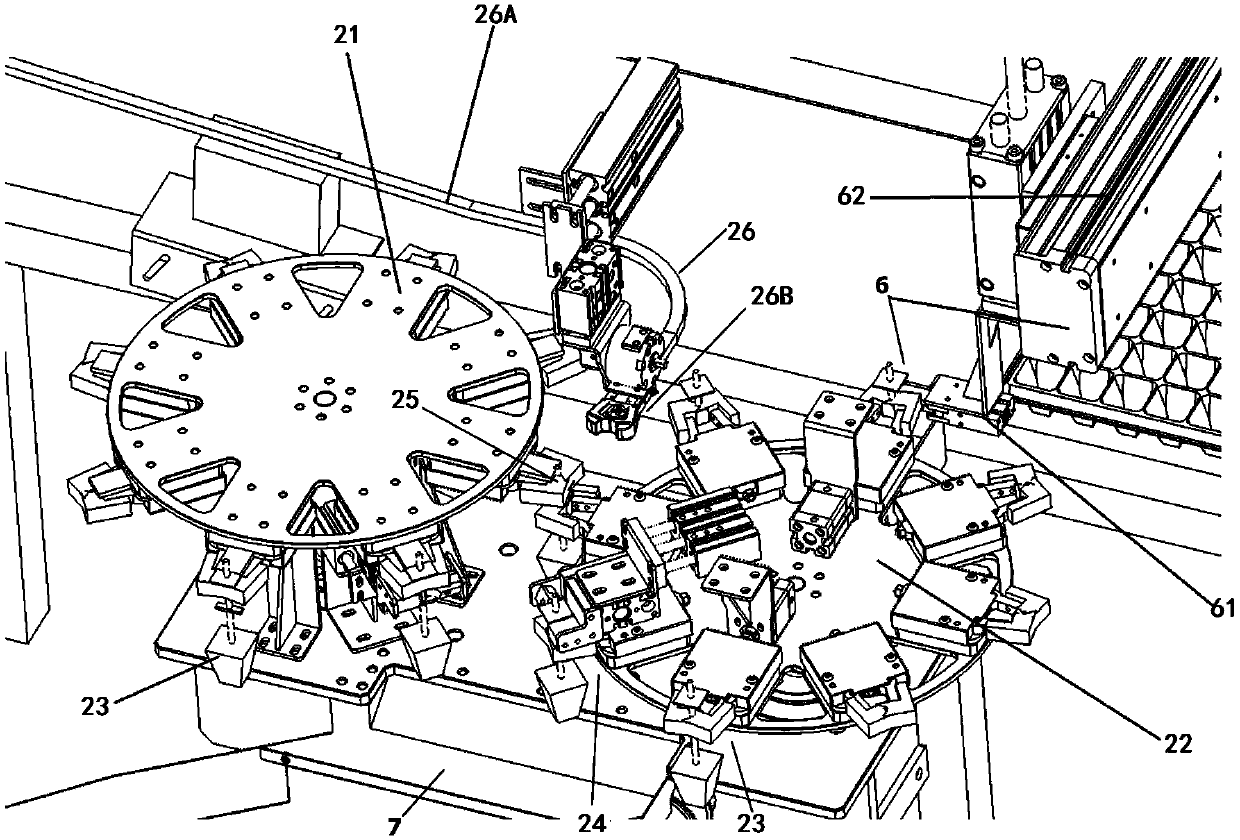

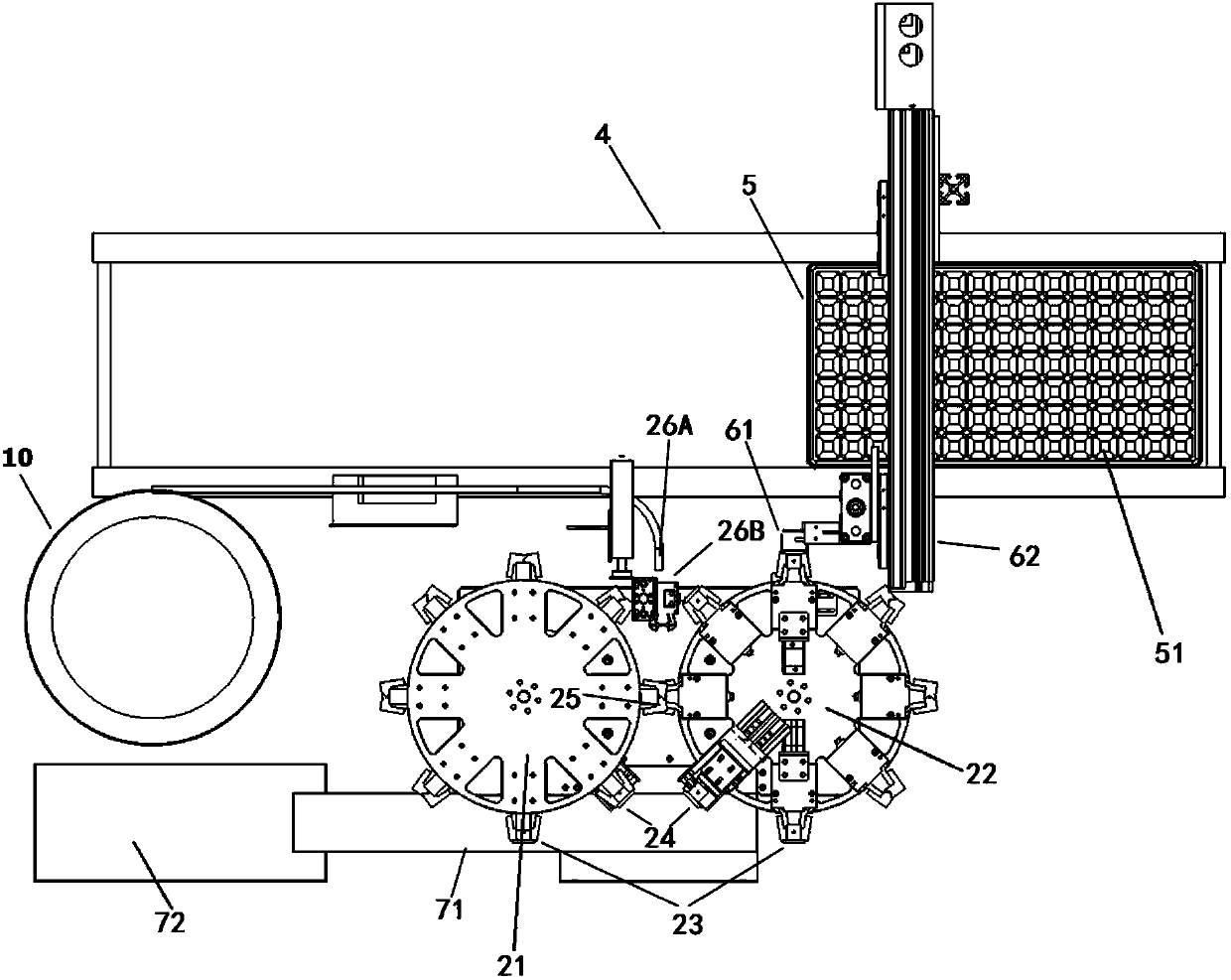

[0020] A front perspective view of a multi-station automatic grafting device provided in an embodiment of the present invention, as shown in figure 1 As shown, in this embodiment, the described multi-station automatic grafting equipment is provided with a base frame 1, and is also provided with a grafting host 2, a vibrating conveying tray 3, Conveyor line 4 and finished product tray 5 , as well as a blanking assembly 6 that straddles the finished product tray 5 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com