apical modification cu 2 ZnO nanorod heterojunction of o and its preparation method and application

A nanorod, heterojunction technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of long time consumption, high reaction temperature, complex preparation process, etc., and achieve short time consumption. , the effect of few reaction steps and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

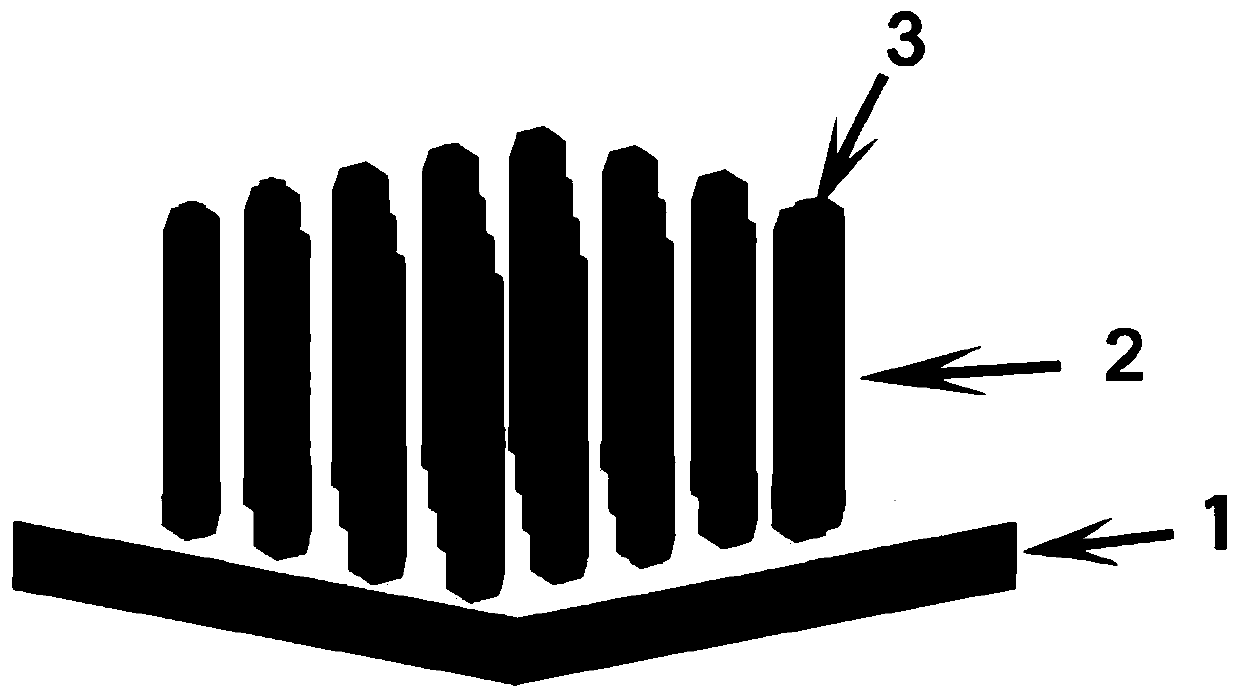

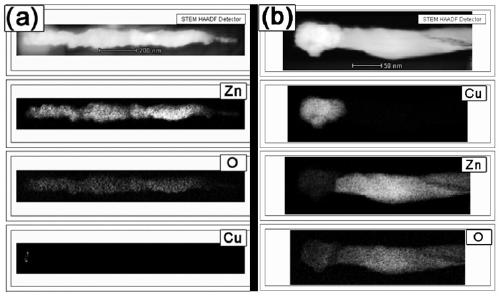

[0039] The top modified Cu of the present invention 2 The preparation method of the ZnO nanorod heterojunction of O comprises the following steps:

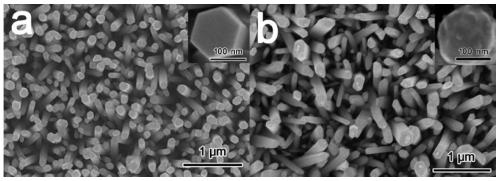

[0040] A) Prepare 0.001mol L -1 Zn(NO 3 )·6H 2 O, 0.1mol L -1 KCl aqueous solution, the constant temperature of the solution was controlled at 70 °C, with FTO conductive glass as the substrate, platinum sheet as the counter electrode, and a saturated calomel electrode as the reference electrode, the constant potential deposition method was adopted, the applied potential was -1.0V, and the deposition time was controlled as After 150min, the ZnO nanorod arrays grown on the surface of FTO were obtained. The ZnO nanorods obtained above were thoroughly washed with water three times to remove residual ions on the surface and dried. The SEM image is as follows figure 1 As shown in a, the ZnO nanorods in the figure have a hexagonal prism structure with a diameter of 80-150 nm.

[0041] B) The preparation concentration is 0.001mol L ...

Embodiment 2

[0044] The top modified Cu of the present invention 2 The preparation method of the ZnO nanorod heterojunction of O comprises the following steps:

[0045] A) Prepare 0.05mol·L -1 ZnCl 2 , 0.05mol·L -1 Ethylenediamine aqueous solution, the constant temperature of the solution is controlled at 85°C, the FTO conductive glass is used as the substrate, the platinum sheet is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode. The constant potential deposition method is adopted, and the applied potential is -1.1V to control the deposition. The time is 90 minutes, and the ZnO nanorod array grown on the surface of FTO is obtained. The ZnO nanorods obtained above are thoroughly washed with water three times to remove residual ions on the surface, and dried.

[0046] B) The preparation concentration is 0.0001mol L -1 CuCl 2 Aqueous solution, adding methanol with a mass fraction of 5%, adjusting the pH of the solution to 9.0 with Na...

Embodiment 3

[0049] The top modified Cu of the present invention 2 The preparation method of the ZnO nanorod heterojunction of O comprises the following steps:

[0050] A) Prepare 0.03mol·L -1 Zn(CH 3 COO) 2 , 0.03mol·L -1 Hexamethylenetetramine aqueous solution, the constant temperature of the solution is controlled at 80°C, the FTO conductive glass is used as the substrate, the platinum sheet is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode. The constant potential deposition method is adopted, and the applied potential is -1.045 V, the deposition time is controlled to be 60min to obtain ZnO nanorod arrays grown on the surface of FTO, the ZnO nanorods obtained above are thoroughly washed with water three times to remove residual ions on the surface, and dried.

[0051] B) The preparation concentration is 0.001mol L -1 CuSO 4 Aqueous solution, adding methanol with a mass fraction of 5%, adjusting the pH of the solution to 9.0 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com