a kind of nimoo 4 Z-based heterojunction photocatalyst and its preparation and application

A photocatalyst and heterojunction technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of limited catalyst application and serious photogenerated carrier recombination and other problems, to achieve excellent photocatalytic hydrogen evolution performance, biomass reforming hydrogen production performance, high atomic utilization rate, and the effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation process of the present invention is as follows:

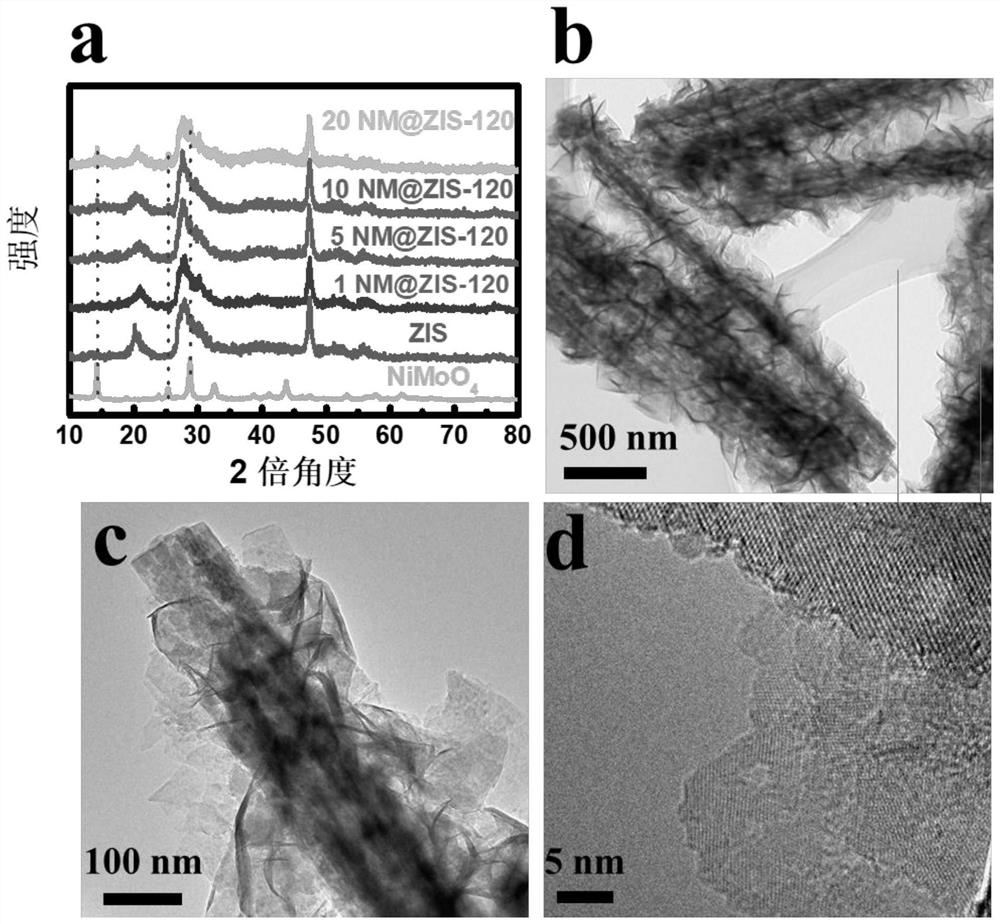

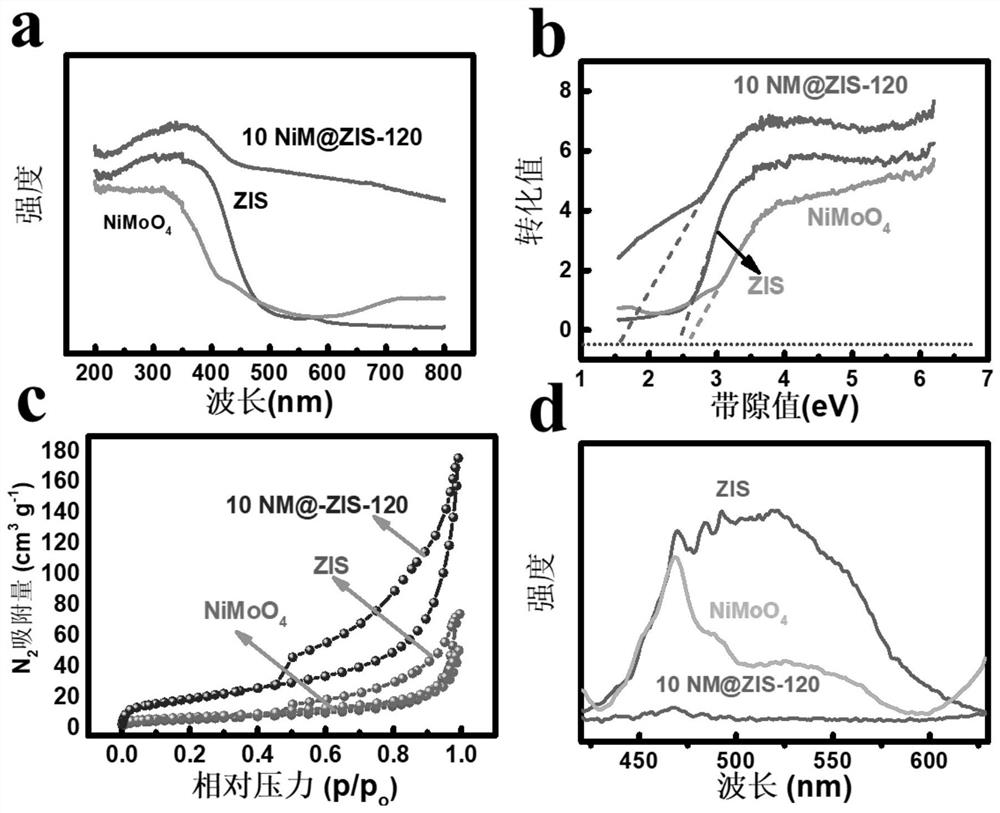

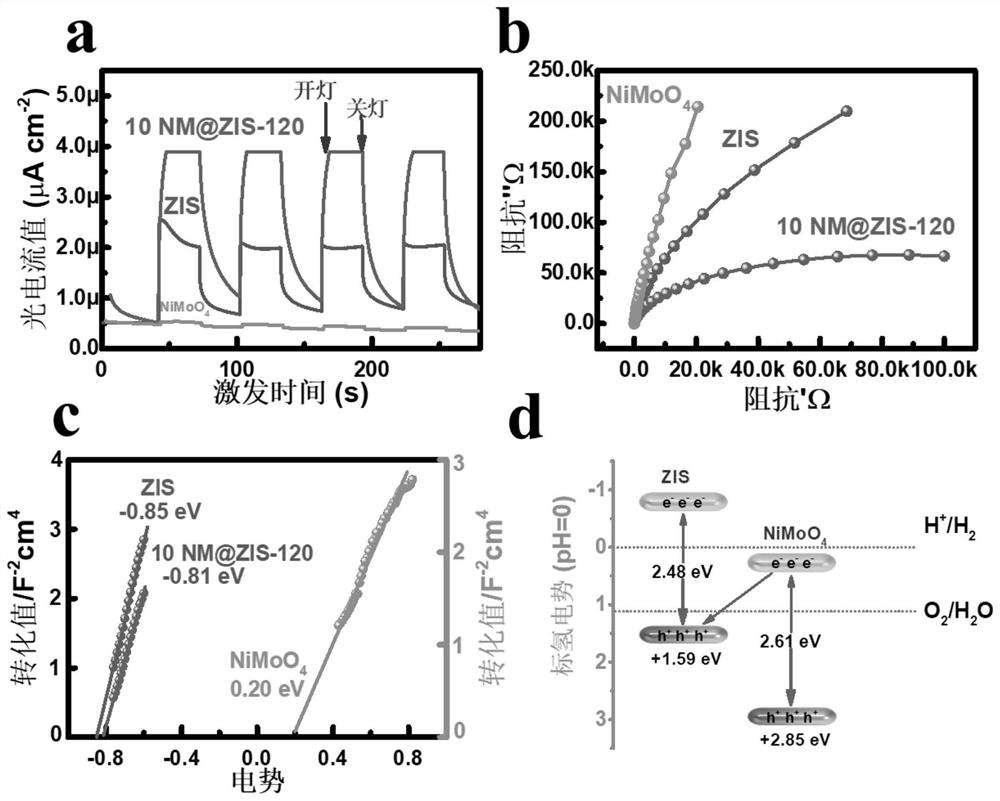

[0046] Synthesis of NiMoO by hydrothermal process and calcination process 4 , the NiMoO 4 (8.46-169.2g) was added to 40ml of ethylene glycol solvent and sonicated for 10min, then the zinc source, indium chloride tetrahydrate, and thioacetamide were dissolved in the above ethylene glycol solution at a mass ratio of 272:1172:600 , stirred evenly for 20 minutes and transferred to a high-pressure reactor, kept at 80-120°C for 2 hours, cooled naturally to room temperature, and the obtained product was centrifugally washed with absolute ethanol, and vacuum-dried to obtain different Mo-doped Ni-loaded ZIS-wrapped NM system photocatalysts. named x NM@ZIS-y (x: NiMoO 4 Added mass percent; y: reaction temperature).

[0047] Test Conditions:

[0048] Using triethanolamine as a sacrificial agent: 10mg catalyst + 100mL triethanolamine aqueous solution (10ml triethanolamine + 90ml water), under a 300W xenon lamp wi...

Embodiment 1

[0053] Dissolve 0.25g of ammonium molybdate tetrahydrate in 30mL of deionized aqueous solution, stir evenly, add 0.2 g of nickel nitrate tetrahydrate, ultrasonicate for 10 minutes, then transfer to a high-pressure reactor, keep warm at 180°C for 10 hours, and cool naturally to room temperature. Washed with deionized water and absolute ethanol three times respectively, and vacuum dried to obtain NiMoO 4 hydrate, and finally raise the temperature from room temperature to 450°C at a heating rate of 5°C / min and hold it for 2 hours to obtain NiMoO 4 . 8.46mg NiMoO 4 Disperse in 40mL of ethylene glycol and sonicate for 10min; dissolve 272mg of anhydrous zinc chloride, 1172mg of indium chloride tetrahydrate, and 600mg of thioacetamide in the above ethylene glycol solution, stir evenly for 30min and transfer to a high-pressure reactor , kept at 120°C for 2 h, cooled naturally to room temperature, and the obtained product was centrifuged and washed three times with absolute ethanol, ...

Embodiment 2

[0055] Dissolve 0.25g of ammonium molybdate tetrahydrate in 30mL of deionized aqueous solution, stir evenly, add 0.2 g of nickel nitrate tetrahydrate, ultrasonicate for 10 minutes, then transfer to a high-pressure reactor, keep warm at 180°C for 10 hours, and cool naturally to room temperature. Washed with deionized water and absolute ethanol three times respectively, and vacuum dried to obtain NiMoO 4 hydrate, and finally raise the temperature from room temperature to 450°C at a heating rate of 5°C / min and hold it for 2 hours to obtain NiMoO 4 . 42.3mg NiMoO 4 Disperse in 40mL of ethylene glycol and sonicate for 10min; dissolve 272mg of anhydrous zinc chloride, 1172mg of indium chloride tetrahydrate, and 600mg of thioacetamide in the above ethylene glycol solution, stir evenly for 30min and transfer to a high-pressure reactor , kept at 120°C for 2 h, cooled naturally to room temperature, and the obtained product was centrifuged and washed three times with absolute ethanol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com