An anti-tangle wire drawing machine

A wire drawing machine and frame technology, which is applied in the field of plastic processing, can solve the problems of wire winding of the roller, overload damage of the first motor, etc., and achieve the effects of avoiding waste, reducing losses and facilitating cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

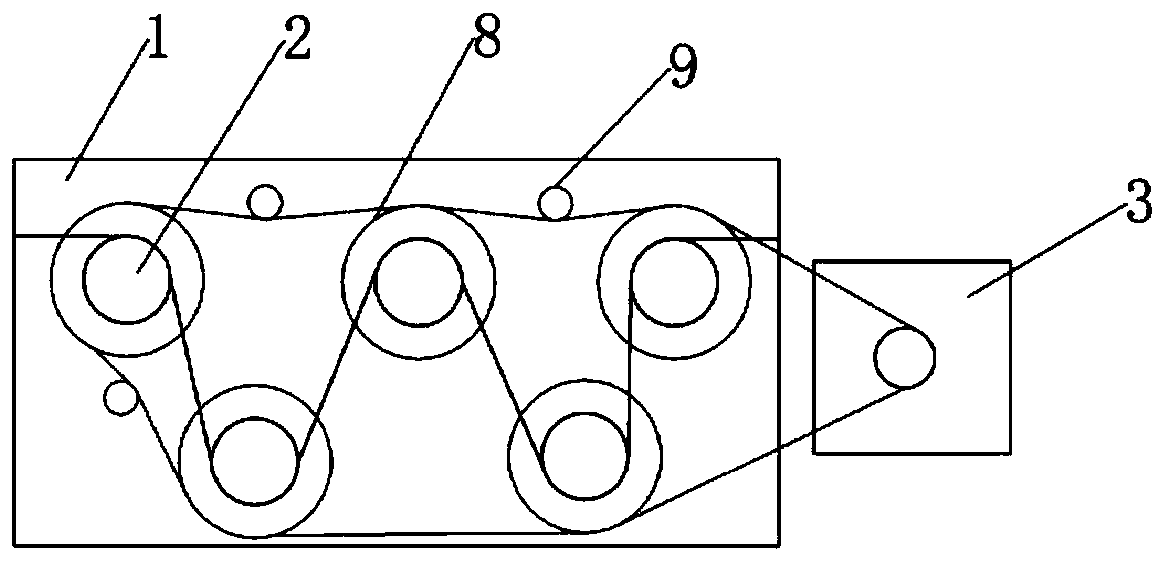

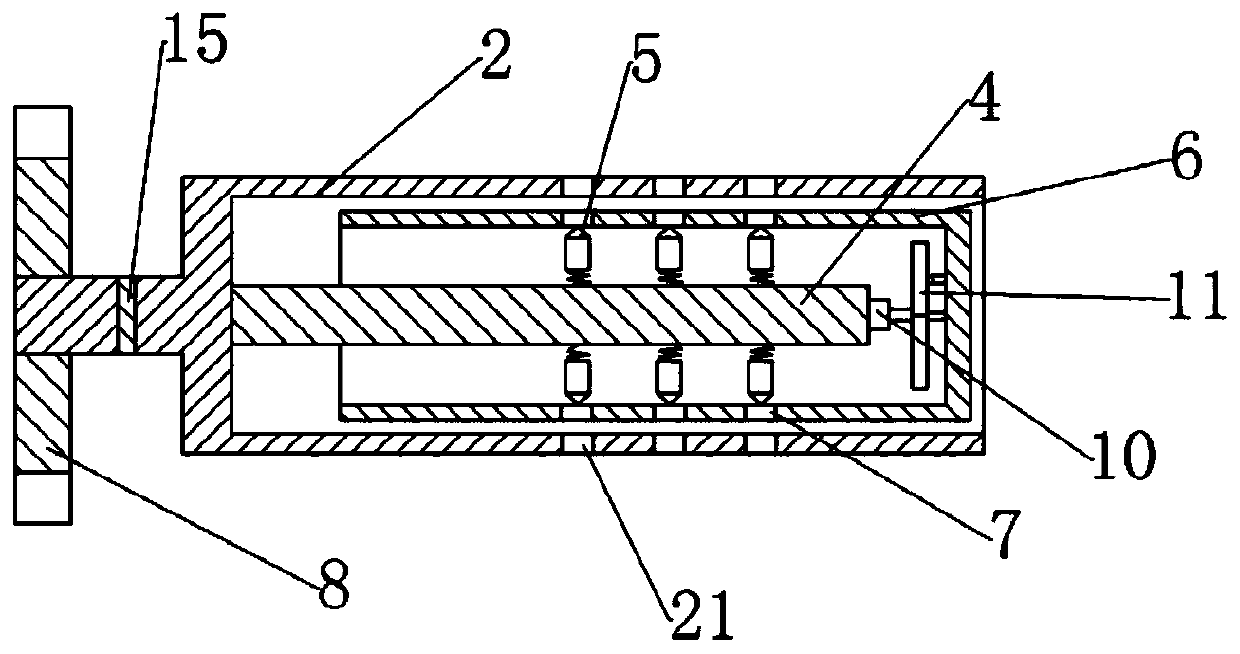

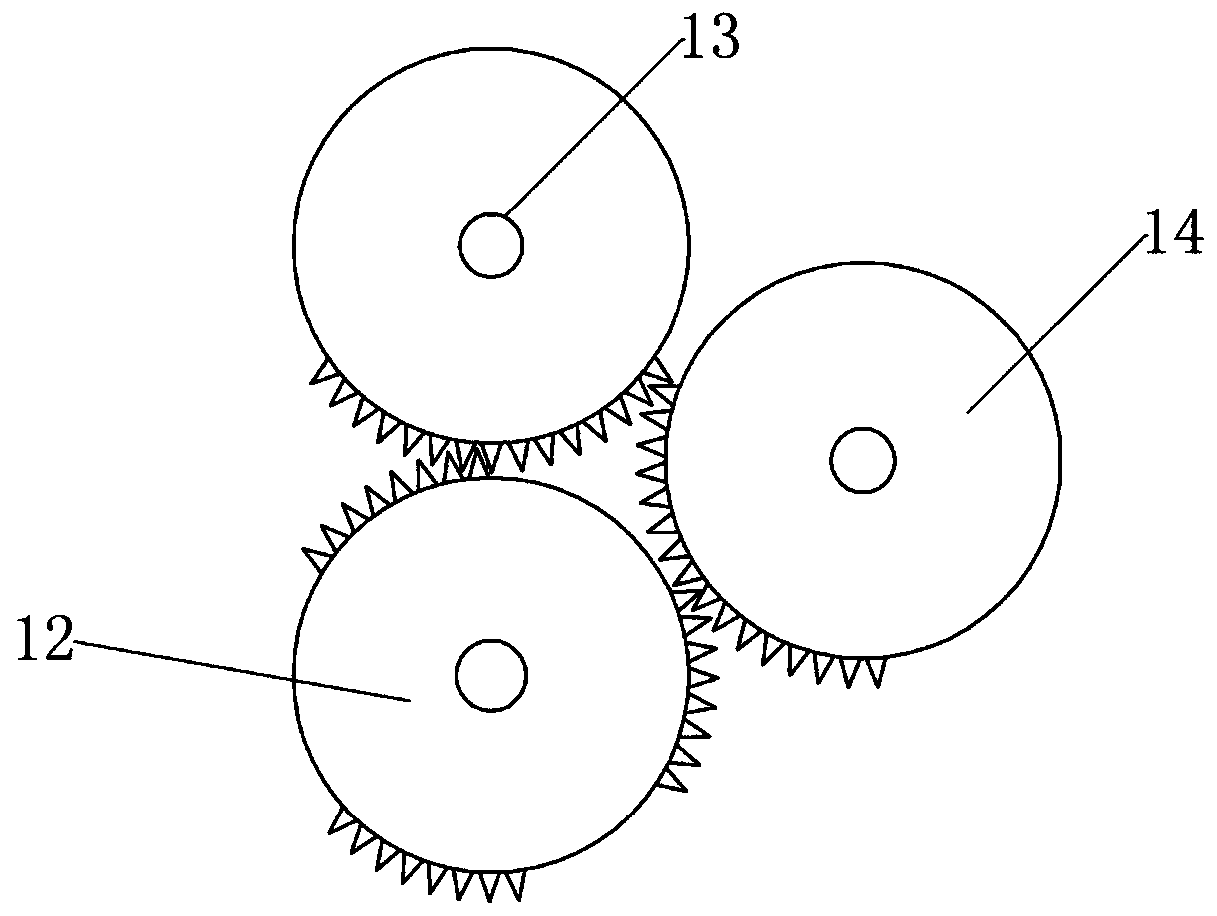

[0021] The reference signs in the drawings of the description include: frame 1, roller 2, first through hole 21, first motor 3, knife holder 4, cutting blade 5, limit sleeve 6, second through hole 7, sprocket 8. Tension pulley 9, second motor 10, gear set 11, first gear 12, second gear 13, third gear 14, torque limiter 15.

[0022] Such as Figure 1 to Figure 2 Shown: a wire drawing machine for anti-winding, including a frame 1, a transmission shaft, a roller 2 and a first motor 3, the rollers 2 are interlaced on the frame 1, and the rollers 2 are parallel to each other, and the rollers 2 and the frame 1 are connected by rolling bearings; a sprocket 8 is installed on the output shaft of the first motor 3, and a sprocket 8 is also installed on the transmission shaft. The first motor is connected with the transmission shaft through a transmission chain, and the transmission shaft passes through st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com