Process for improving mobility of Nixing ceramic dry powder blank material

A Nixing pottery and fluidity technology, which is applied in the technical field of improving the fluidity of Nixing pottery dry powder billet, to achieve the effect of enhancing dispersion, regular shape, reducing distortion and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

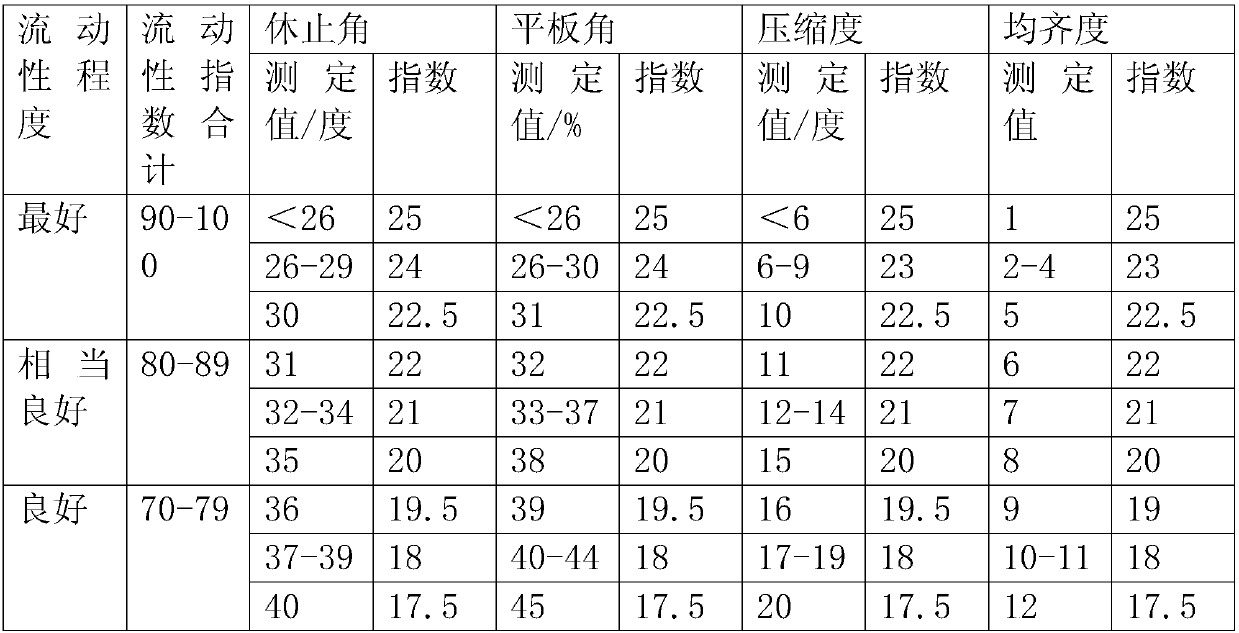

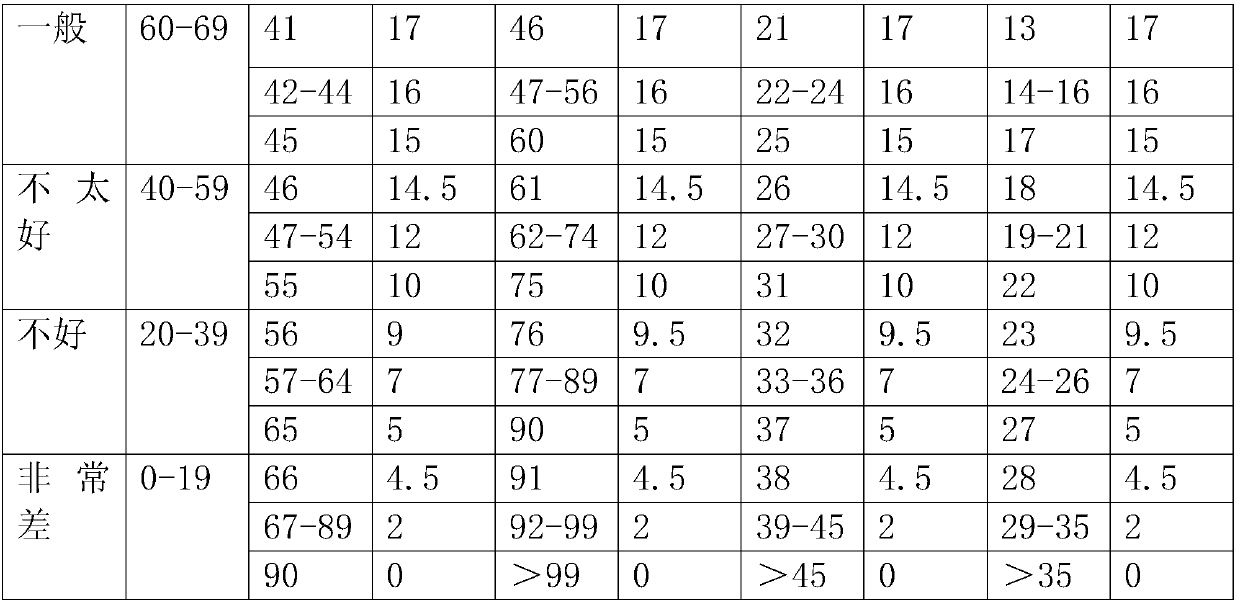

Image

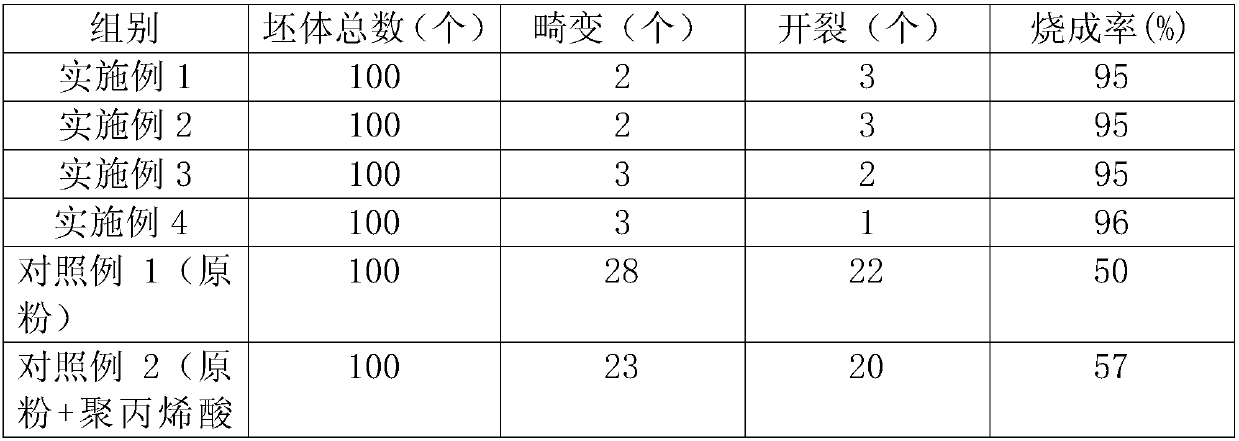

Examples

Embodiment 1

[0017] 1) Take east mud and west mud and mix them at a weight ratio of 4:6 to obtain Nixing pottery mud, add 0.1% of its weight SiC particles, mix and grind to 200 mesh, first place it at 500MHz for 20min, and then put it at 100GHz Down processing 1min, obtains potter's clay powder;

[0018] 2) After mixing 0.5% sodium polyacrylate by weight into the pottery clay powder, send it into a dry granulator for humidification and granulation to obtain a powder with a moisture content of 12%;

[0019] 3) Dry the powder until the water content is 6%.

Embodiment 2

[0021] 1) Take east mud and west mud and mix them at a weight ratio of 6:4 to obtain Nixing pottery mud, add 0.5% of its weight SiC particles, mix and grind to 300 mesh, first place it at 1000MHz for 25min, then place it at 200GHz Down processing 3min, obtains potter's clay powder;

[0022] 2) After mixing 1% sodium polyacrylate by weight into the pottery clay powder, send it into a dry granulator for humidification and granulation to obtain a powder with a moisture content of 15%;

[0023] 3) Dry the powder until the moisture content is 7%.

Embodiment 3

[0025] 1) Take east mud and west mud and mix them at a weight ratio of 5:5 to obtain Nixing pottery mud, add 0.25% of its weight SiC particles, mix and grind to 250 mesh, first place it at 800MHz for 22min, then place it at 150GHz Down processing 2min, obtains potter's clay powder;

[0026] 2) After mixing 0.8% sodium polyacrylate by weight into the pottery clay powder, send it into a dry granulator for humidification and granulation to obtain a powder with a moisture content of 14%;

[0027] 3) Dry the powder until the water content is 6.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com