Fabric processing system

A processing system and cloth technology, applied in the field of cloth processing, can solve the problems of low processing efficiency, affecting the toughness of the cloth, and taking a long time to achieve the effect of improving the overall efficiency, increasing the deformation function, and improving the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

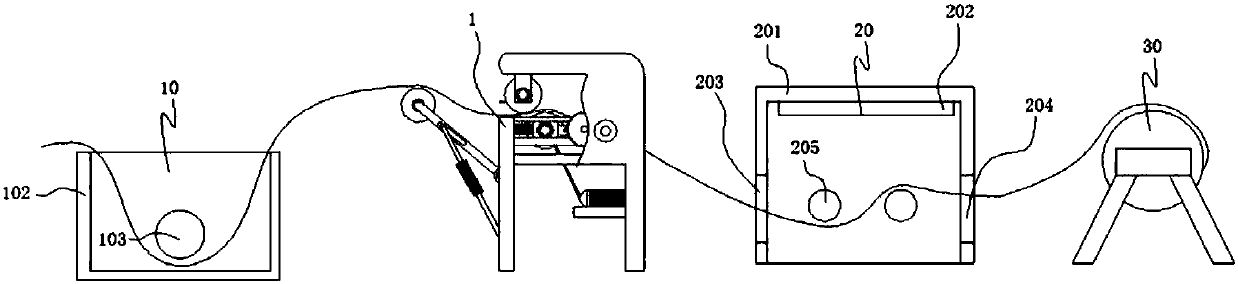

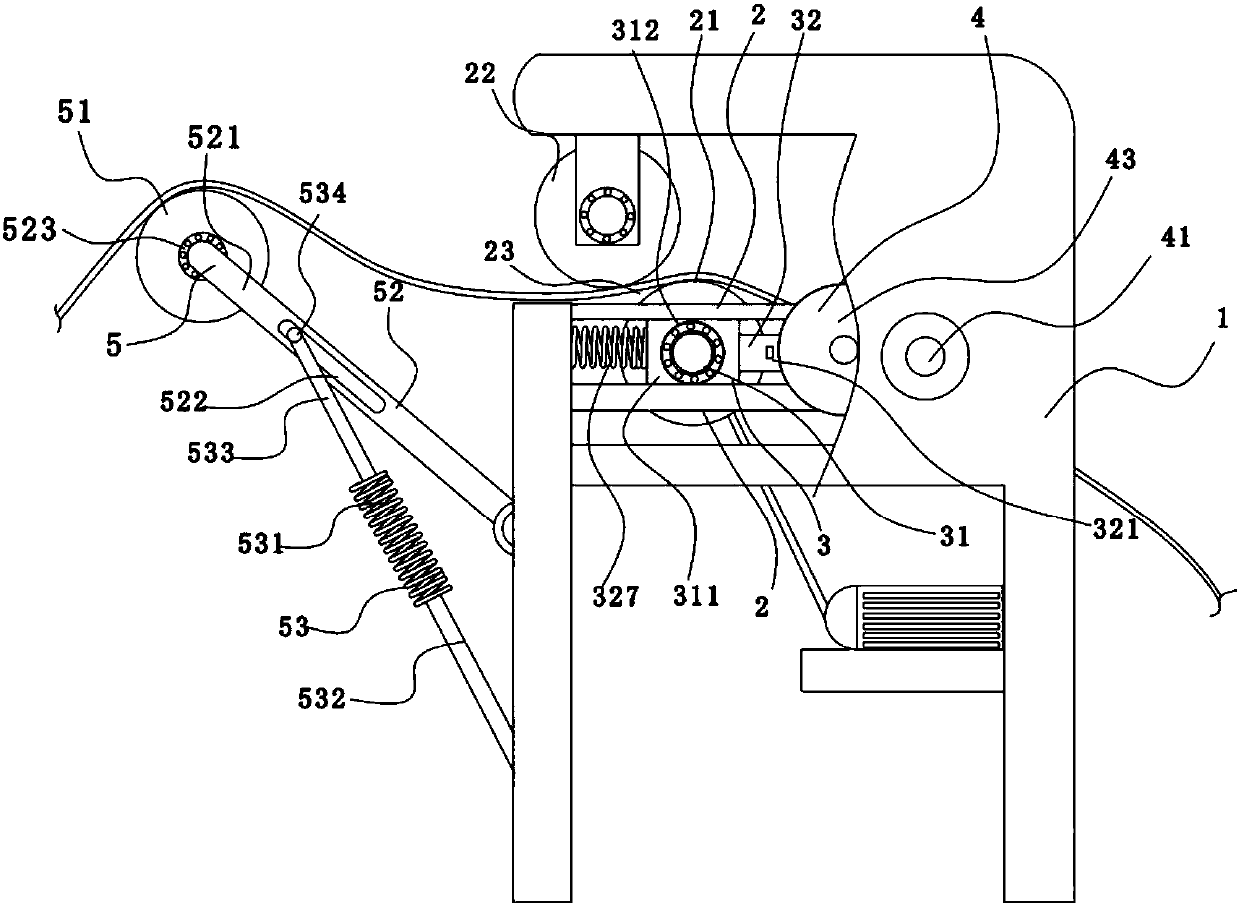

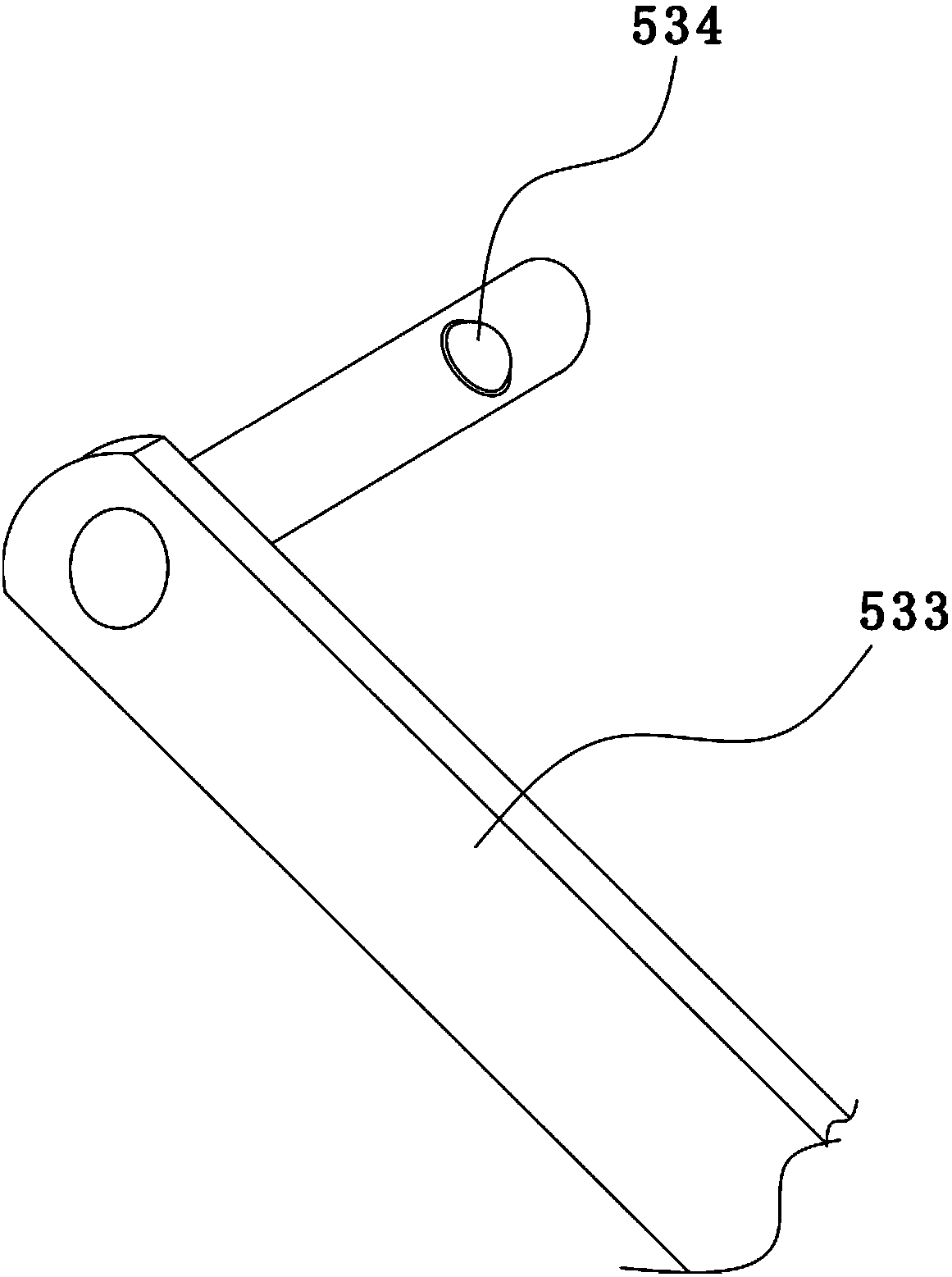

[0021] Such as Figure 1-5 As shown, a cloth processing system includes a dyeing device 10, a dehydration device for squeezing the dyed cloth, a drying device 20 for drying the dehydrated cloth, and a receiving device 30; The dehydration device is located between the dyeing device 10 and the drying device 20; specifically, the dyeing device 10 includes a dyeing pool 102 and a dipping roller 103, the dyeing pool 102 is a stainless steel tank with an upper opening, and the dipping roller 103 is a metal cylinder directly purchased on the market, the dipping roller 103 is rotatably arranged in the dyeing pool 102, and the left and right ends of the dipping roller 103 can be drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com