Metal interconnect structure and fabrication method thereof

A technology of metal interconnection structure and fabrication method, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as affecting yield, short circuit of aluminum lining, and unclean etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

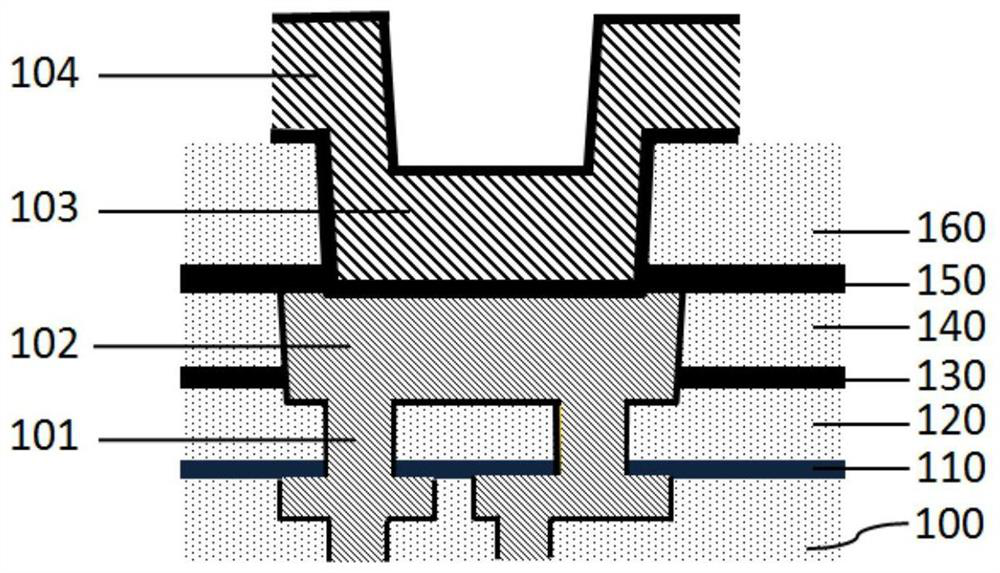

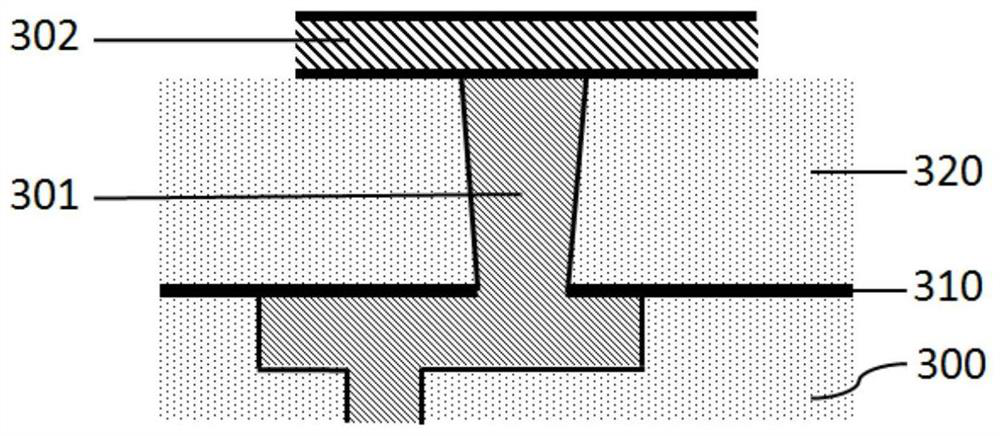

[0041] As described in the background technology, the existing metal interconnection structure manufacturing method has a cumbersome process flow. At the same time, because aluminum is used as a pad, its critical dimension is relatively large, and the thickness of aluminum deposition is also relatively thick. Whisker-shaped defects on the surface of the aluminum pad ( whiskerdefect) will also be exacerbated. When the size of the whisker-shaped defect is large enough, it will cause a short circuit of the adjacent aluminum pad, and in the subsequent metallization pattern etching process, the etching will not be clean and affect the yield.

[0042] Considering that metal aluminum can also be used as a metal connection, and exhibits excellent performance under a certain line width, the aluminum liner layer can be used as both a liner and a top metal layer in a metal interconnection structure.

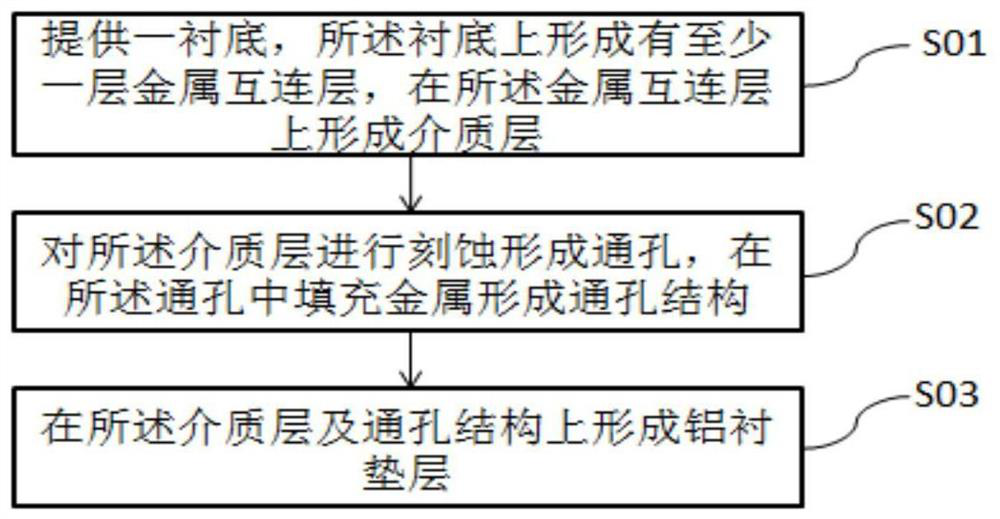

[0043] The invention provides a method for manufacturing a metal interconnection structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com