Self-aligning dual mesa device structure making method

A technology of device structure and fabrication method, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of affecting the consistency between chips, reducing the process yield, wasting chip area, etc., and achieving accurate diameter and size Controllable, improve tape-out efficiency and reduce device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined invention objectives, the specific implementation manners of the present invention will be described below in conjunction with examples of the invention.

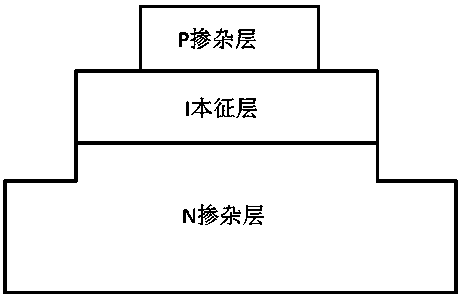

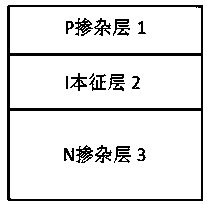

[0032] Select PIN structure GaN material, such as figure 2 shown. An implementation mode corresponding to the fabrication method of the self-aligned double-mesa device structure of the present invention is as follows:

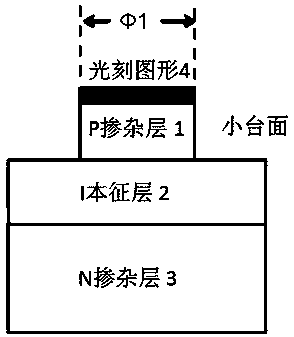

[0033] Step 1, prepare a small mesa photolithographic pattern 4 on the P-doped layer, such as image 3 shown.

[0034] The photoresist used in the implementation is AZ4620, and the photoresist spin-coating condition is: 2000 revolutions, 30 seconds. After pre-baking at 100°C for 150 seconds, photolithographic exposure for 40 seconds, and developing with a developer for 2 minutes, a small mesa photolithographic pattern 4 is formed. The obtained photolithographic pattern 4 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com