Automotive carpet foaming production line

A technology for automotive carpets and production lines, which is applied to household components, household appliances, and other household appliances. It can solve the problems of uneven material, low production efficiency, and large energy consumption, and achieve uniform density and ensure quality and consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

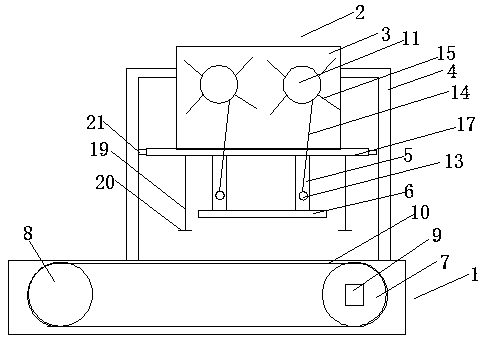

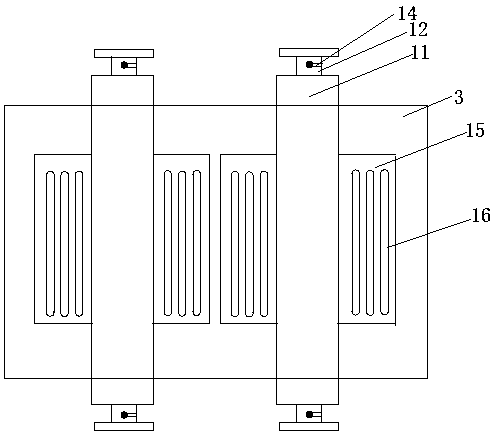

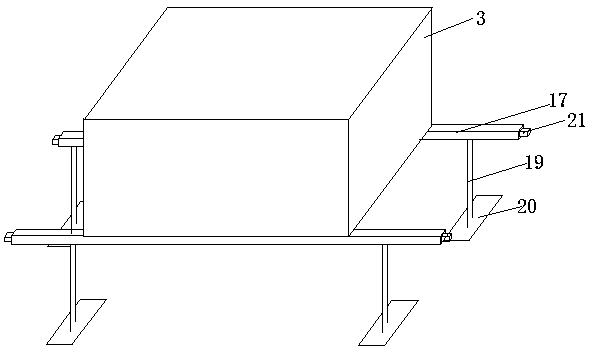

[0014] Attached below Figure 1-3 The structure, principle and working process of the present invention will be further described with specific embodiments, but the protection scope of the present invention is not limited thereto.

[0015] A foaming production line for automobile carpets, comprising a lower conveying device 1 and an upper foaming device 2, the foaming device 2 comprising a holding furnace 3, supports 4 positioned on both sides of the holding furnace 3, connected to the holding The injection cavity 5 at the bottom of the furnace 3 and the automobile carpet foam mold 6 connected to the bottom of the injection cavity 5, the injection cavity 5 is telescopic, and the injection cavity 5 is connected with a motor; the transmission device 1 Including the driving wheel 7 at the right end, the driven wheel 8 at the left end and the chain 10 connecting the driving wheel 7 and the driven wheel 8, the total motor 9 is connected to the driving wheel 7; this device can reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com