Laser welding and combined molding device and method of well seat of large-size plastic inspection well

A plastic inspection well and combined molding technology, which is applied in the field of large-scale plastic inspection well forming and processing, can solve the problems of high design and manufacturing cost of large-scale plastic inspection well well seat molds, and achieve convenient and flexible equipment operation, uniform welding seam and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

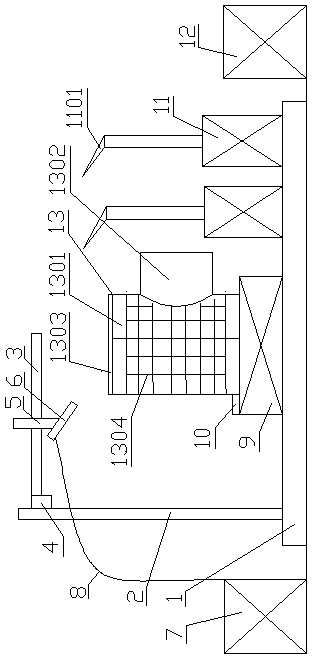

[0034] A laser welding combined forming method for a large plastic inspection well seat, the laser welding combined forming steps are as follows:

[0035] ①. The well base 1303 and each side panel 1301 of the large plastic inspection well base 13 are respectively processed by injection molding, and the absorbing layer is sprayed on the welding surface of the well base 1303 and each single side panel 1301. The absorbing layer is black Paints or coatings with an absorbing layer thickness of 0.5-5 microns;

[0036] ②. Set the trajectory and speed of the laser spot output by the laser output controller 6, that is, the linear motion welding trajectory of the spot at the welding surface of each single-side panel 1301, the slope surface of the combined single-side panel and the bottom plate 1303 of the well base The rotary motion welding is completed by the cooperation of the rotary table 9, and the working parameters of the semiconductor laser 7 are set, as well as the contact press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com