Detector for lead-acid storage battery pole plate

A technology of lead-acid batteries and detectors, applied in electromagnetic measuring devices, electric/magnetic thickness measuring, instruments, etc., can solve the problems of complicated data processing and inability to monitor the quality of polar plates on-line, and achieve simple devices, continuous inspection and monitoring The effect of plate quality, significant economic benefits and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

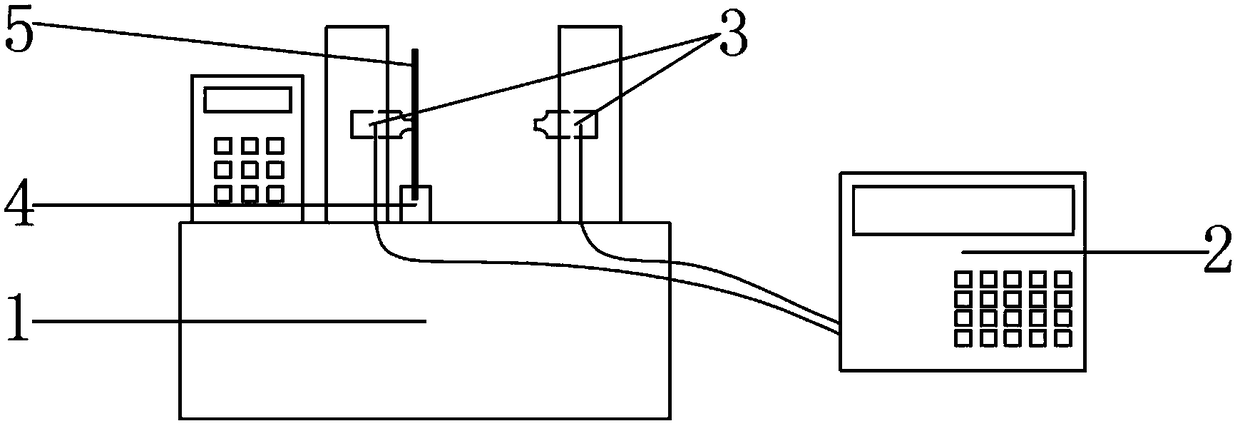

[0030] Please check figure 1 and 3 , a kind of lead-acid storage battery polar plate tester of the present embodiment, comprises pressure testing machine 1, impedance tester 2, probe 3 and data collection and processing device;

[0031] The pressure testing machine 1 includes a column and a supporting device 4 arranged on the operating platform, and the supporting device 4 is used to place the pole plate 5 to be tested; the column is provided with a pressure sensor and a probe 3, and the probe 3 points to the direction of the electrode plate 5 to be tested, and is used to collect the distance between the probes 3 and the pressure value;

[0032] The impedance tester 2 is connected to the probe 3 through a wire, and is used to collect a DC resistance value or an AC impedance value;

[0033] The data collection and processing device is connected with the pressure testing machine 1 and the impedance testing machine 2, and is used to collect the data of the two, and perform vari...

Embodiment 2

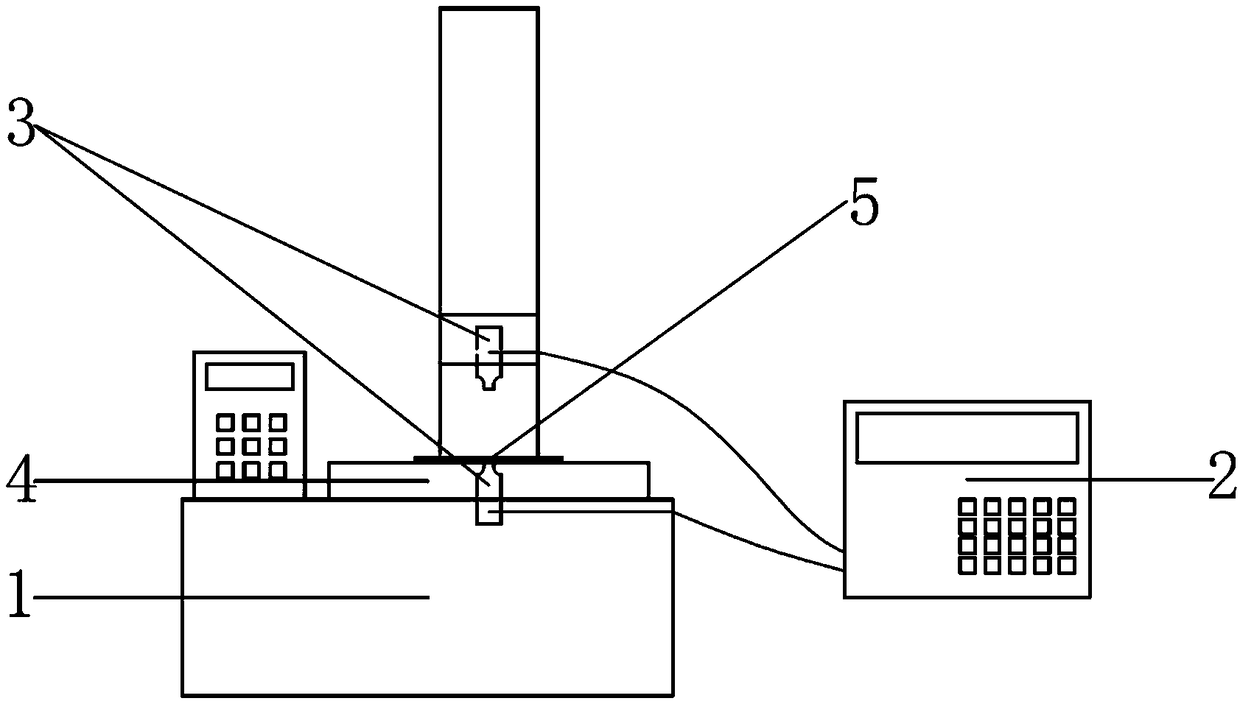

[0064] Please check figure 2 , the difference between embodiment 2 and embodiment 1 is:

[0065] In this embodiment, a single-column pressure testing machine 1 and an insulation resistance tester 2 are used.

[0066] The pressure testing machine 1 is driven by the motor to rotate the movable end on the column, and the tested specimen is loaded through the movable end, which has enough space for the test stroke, and the servo system with high speed regulation accuracy and stable performance can be used to complete the sample test. Compression and other mechanical properties tests. The base of the pressure testing machine 1 of the present embodiment is the operation platform, and the base is static, and the vertical lifting and pressurization mode is moved unilaterally to realize single or continuous pressurization. Its pressure range is 0-500N (or different range pressure sensors can be replaced according to actual needs), stroke 0-900mm, displacement rate adjustable range 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com