Cotton and wool fiber air conveying and collecting device

A collection device and air conveying technology, applied in conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of increased production cost, prolonged production and processing cycle, slow falling speed, etc., to reduce material loss and shorten the humidification cycle. , the effect of fast falling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail through embodiments in conjunction with the accompanying drawings.

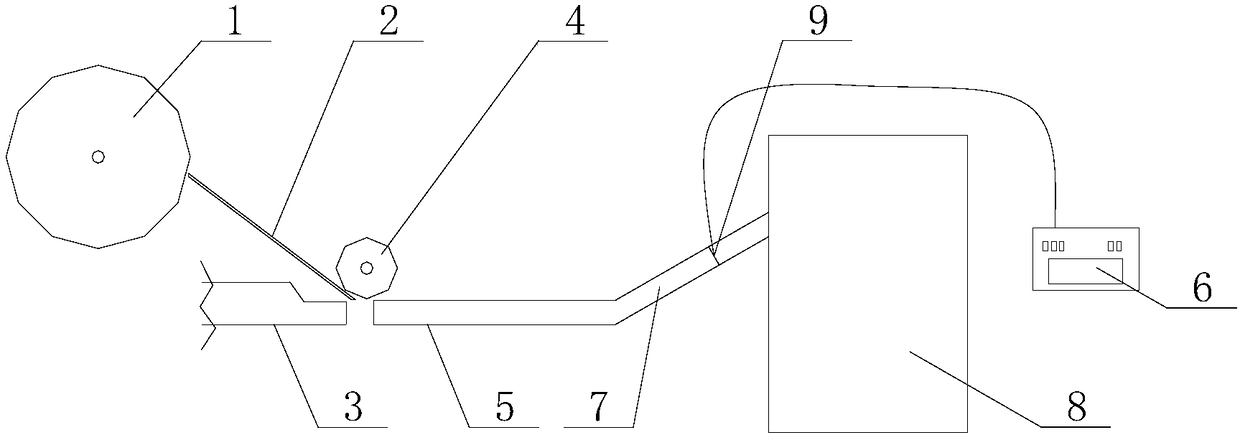

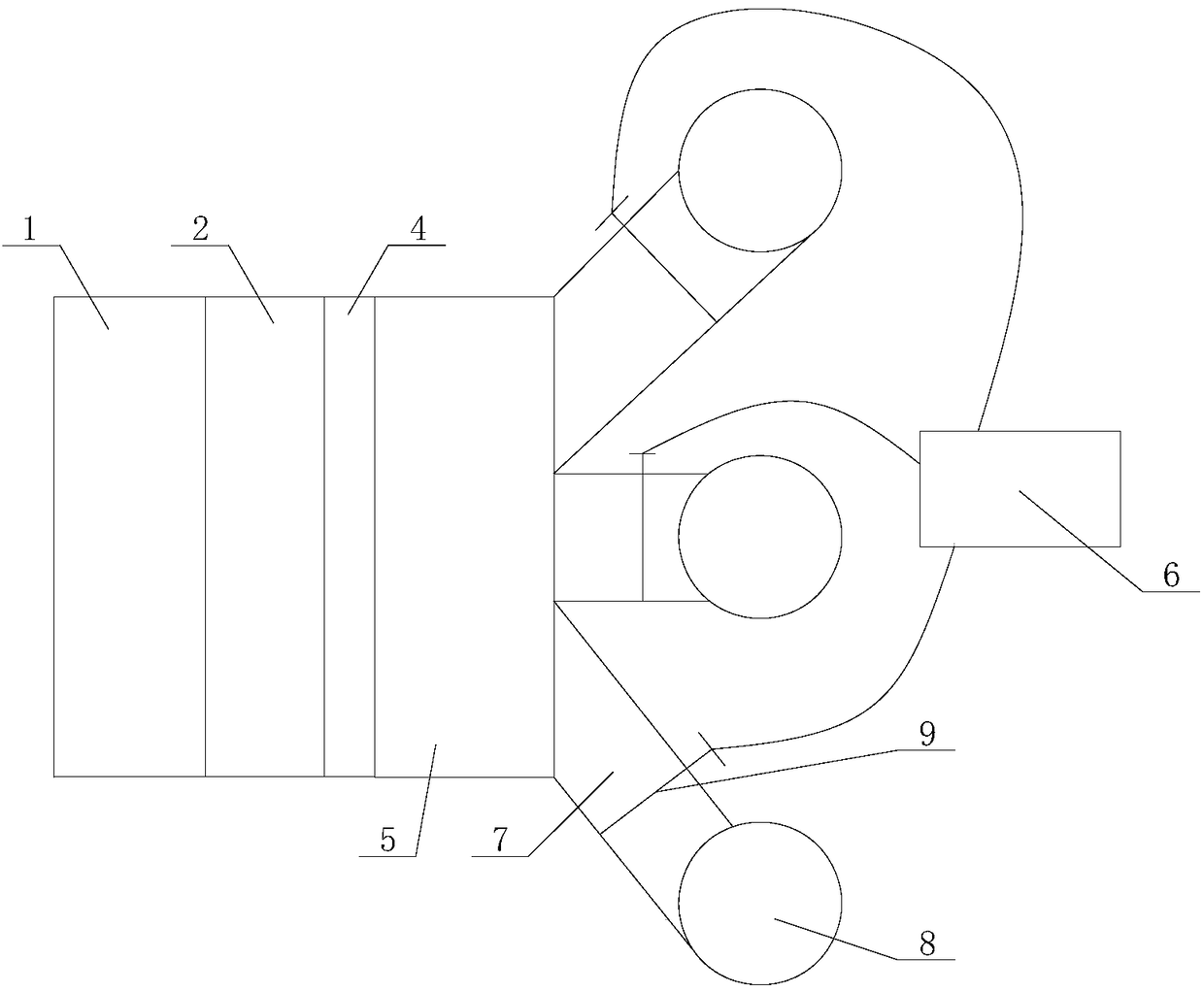

[0010] A wind-sent collection device for cotton and wool fibers, which includes a blowing pipe 3, a material guide roller 4, a material air-sending pipe 5, an intermittent shut-off device 6, three material distribution pipes 7, three barrel bins 8 and three shut-off valves 9. Below the bottom of the blanking plate 2 at the end of the carding machine 1, there are respectively provided blowing pipes 3 and material air delivery pipes 5 opposite to the nozzle along the material conveying direction; above the blowing pipe 3 and the material air delivery pipe 5 The top of the bottom of the blanking plate 2 is provided with a material guide roller 4; one end of the three distribution pipes 7 is connected with the material air delivery pipe 5; A shut-off valve 9 is arranged on the material pipe 7; the shut-off valve 9 is electrically connected with the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap