Low-temperature in-situ biaxial tensile mechanical property testing device

A technology of biaxial stretching and testing device, which is used in measuring device, using stable tension/pressure to test the strength of materials, scientific instruments, etc., can solve the lack of effective research on the micro-mechanical behavior and damage mechanism of anisotropic materials, The problems of large mechanical structure and incompatibility with microscopic imaging equipment have achieved the effect of good application prospects, small footprint and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

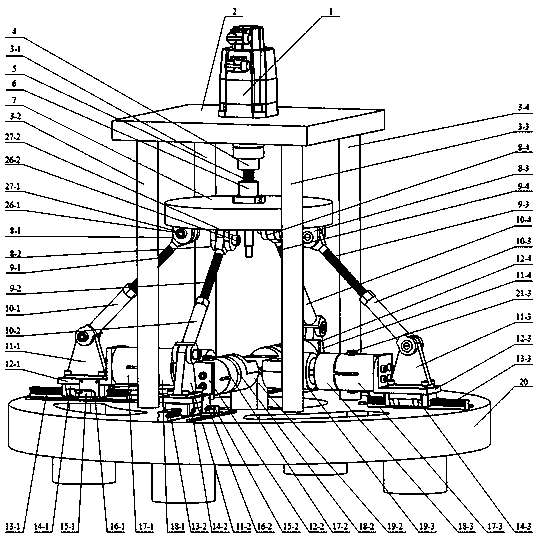

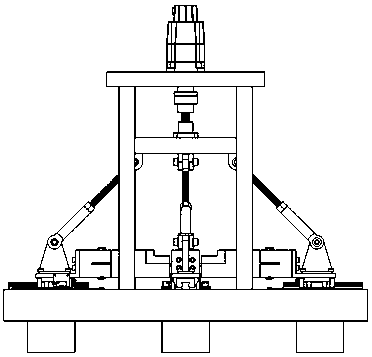

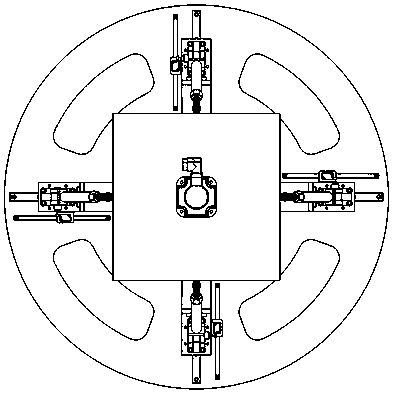

[0038] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0039] see Figure 1 to Figure 9 As shown, the low-temperature in-situ biaxial tensile mechanical performance testing device of the present invention adopts a vertical arrangement as a whole, including a drive unit, a transmission unit, a signal detection unit, a clamping unit and a temperature loading unit. The shaft loading power is provided by a stepping motor; the transmission unit is composed of four centrally symmetrical screw rods, moving guide rods, sliders and linear guide rails to transmit the power of the device. The signal detection unit includes a tension sensor, a linear grating displacement sensor and an optical microscope for in-situ observation, wherein the slider assembled on the linear guide rail drives the stretching connector, the tension sensor and the clamp body to move to achieve stretching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com