Method for determining mixing uniformity of powdery product of dry-process mixing

A mixing uniformity and measuring method technology, applied in the field of mixing uniformity measurement, can solve the problems of cumbersome detection steps, long measurement time and high detection cost, and achieve the effects of fast detection speed, high accuracy and low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] It is 80wt% to measure skimmed milk powder content, and the mixing uniformity of the milk powder after adopting the dry method mixing that lactose content is 20wt%, steps are as follows:

[0035]Take skimmed milk powder and lactose respectively, and adopt PFT powder fluidity measuring instrument (U.S. Brookfield Bo Le Fei Company) to measure the fluidity of both respectively, according to the fluidity function curve that draws, determine the component with little fluidity, The analysis of the fluidity function curve shows that the fluidity of lactose is less than that of skim milk powder, so lactose is used as a tracer;

[0036] 2) Determination of lactose D by Malvern laser diffraction particle size analyzer MS3000 V 10. The particle size values corresponding to Dv50 and Dv90 are determined to be 6 μm, 49 μm and 147 μm respectively, and the effective particle size range is determined to be 6 μm to 147 μm;

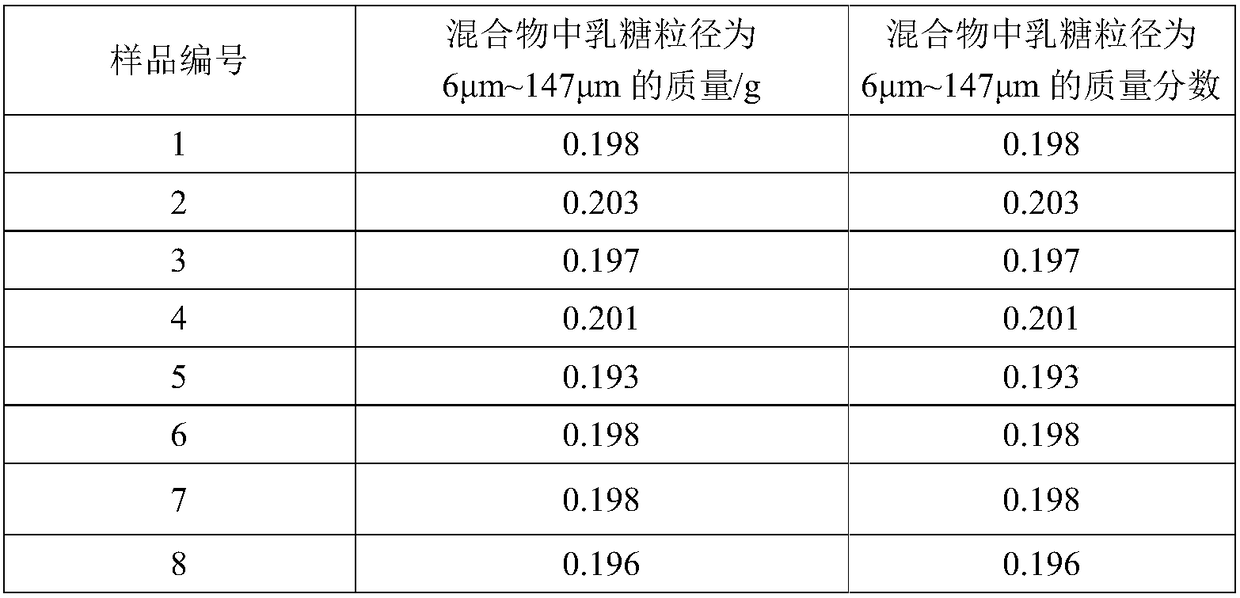

[0037] 3) Use the above-mentioned laser diffraction particl...

Embodiment 2

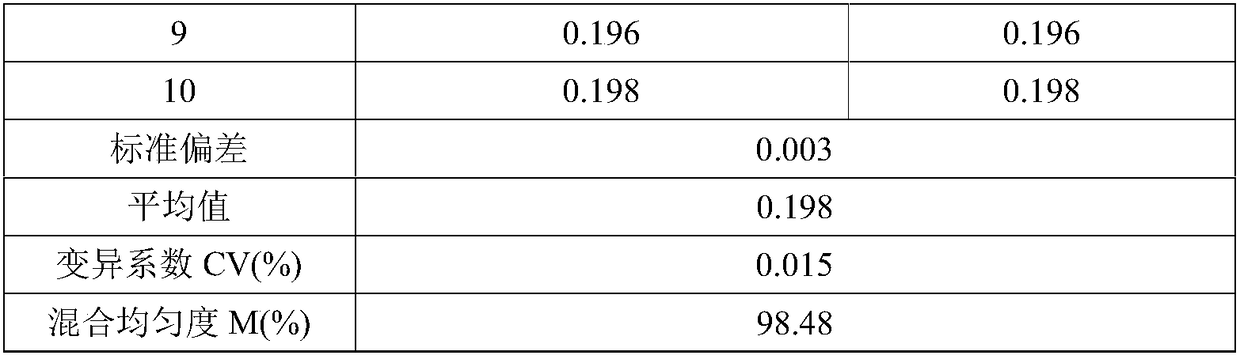

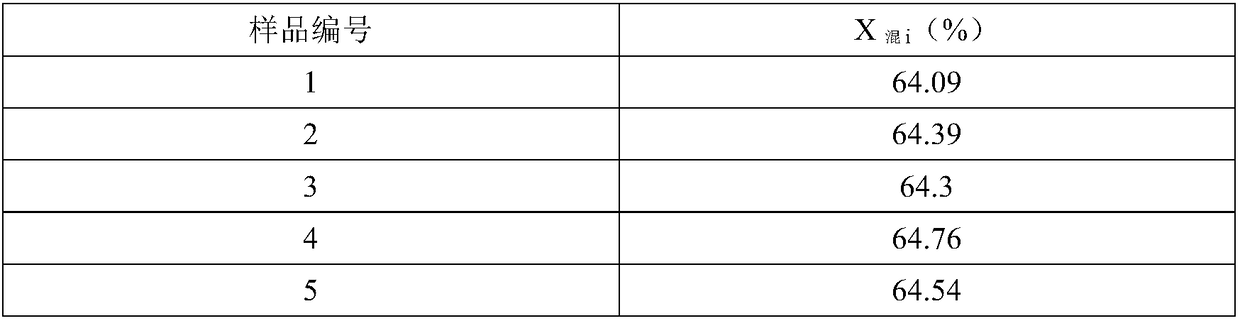

[0049] It is 50wt% to measure the whole milk powder content, the skimmed milk powder content is 30wt%, and the lactose content is the mixing uniformity of the milk powder after adopting the dry mixing of 20wt%, and the steps are as follows:

[0050] 1) Take whole milk powder, skimmed milk powder and lactose respectively, and adopt PFT powder fluidity tester (U.S. Brookfield Brookfield company) to measure the fluidity of the three respectively as in the method in embodiment 1, according to the obtained Mobility function curve, to determine the component with the least fluidity. After analyzing the fluidity function curve, it can be known that lactose has the least fluidity, so lactose is used as a tracer;

[0051] 2) Determination of lactose D by Malvern laser diffraction particle size analyzer MS3000 V 10. The particle size values corresponding to Dv50 and Dv90 are determined to be 6 μm, 49 μm and 147 μm respectively, and the effective particle size range is determined to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com