Method for processing PHOTOALIGNMENT LAYER in appropriate relative humidity range

A processing method and relative humidity technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem of inability to guarantee the alignment quality, and achieve the effect of good alignment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Effect of Relative Humidity on the Photoalignment Quality of Non-composite Azo Dye Films

[0028] In the glove box, place the name tetrasodium 5,5'-((1E,1'E)-(2,2'-disulfonic acid-[1,1'-biphenyl]-4,4'-bis base) bis(diazene-2,1-diyl)) bis(2-hydroxybenzoic acid) (hereinafter referred to as SD1) pure sulfate-based azo dyes dissolved in dimethylformamide solvent at a concentration of 1% Afterwards, the substrate was uniformly covered by spin coating, and the azo dye film covered on the substrate was soft baked at 100°C for 10 minutes, and then the film was placed in a sealed cabin and removed from the glove box, and then the sealed cabin was mixed with humidity The generator is connected to obtain the required relative humidity inside and after equilibrium, use 5mW / cm 2 Linearly polarized 365nm UV light irradiation.

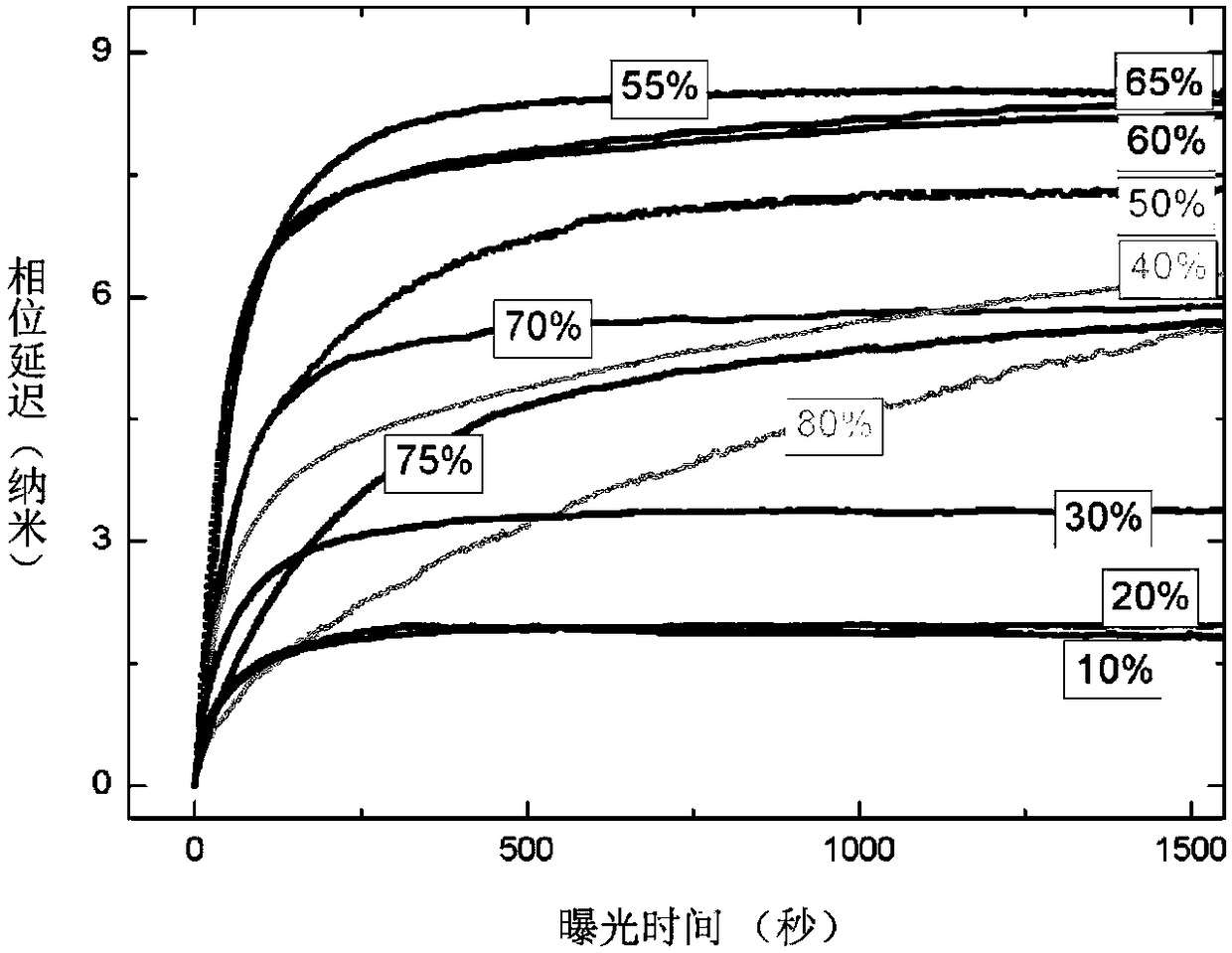

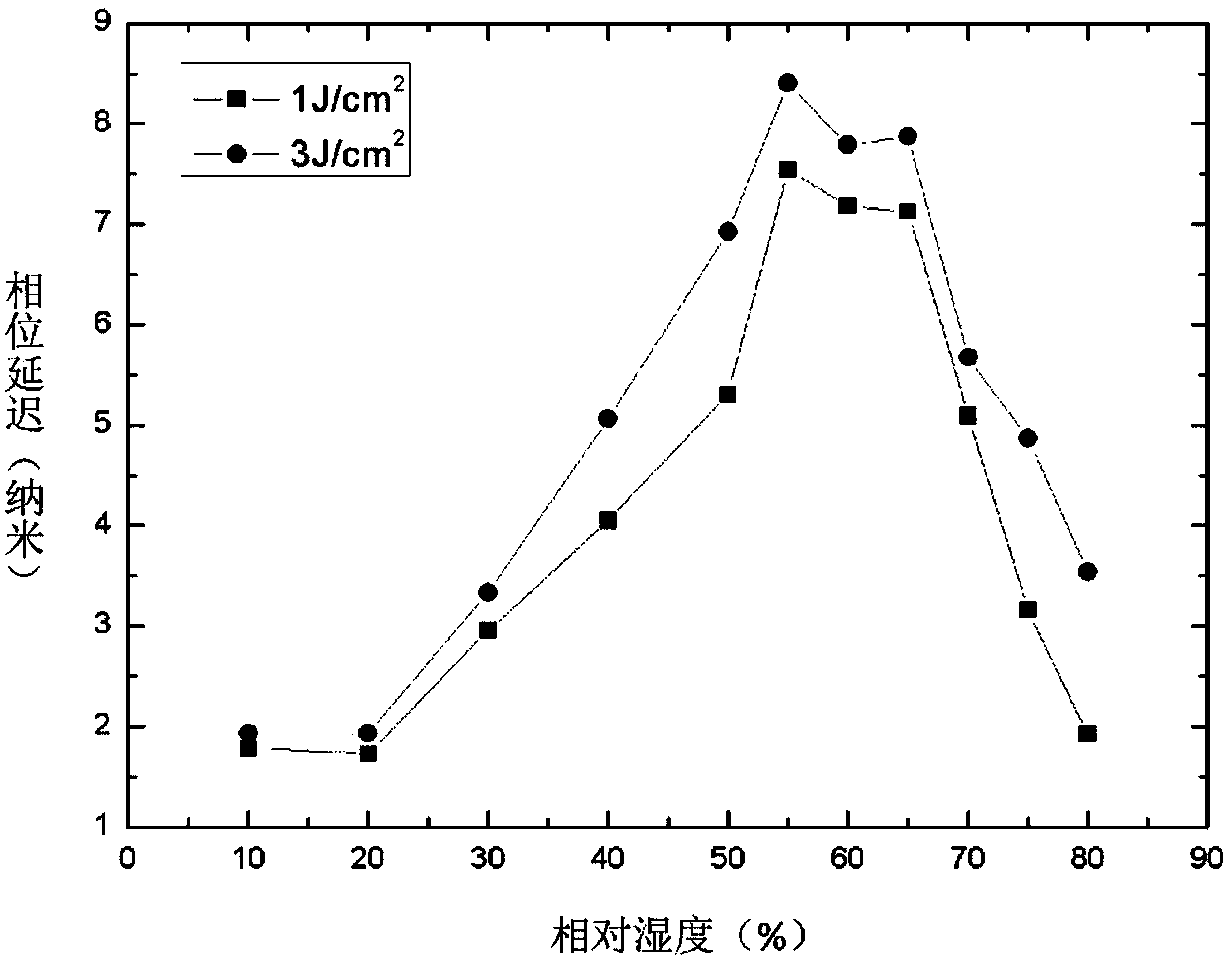

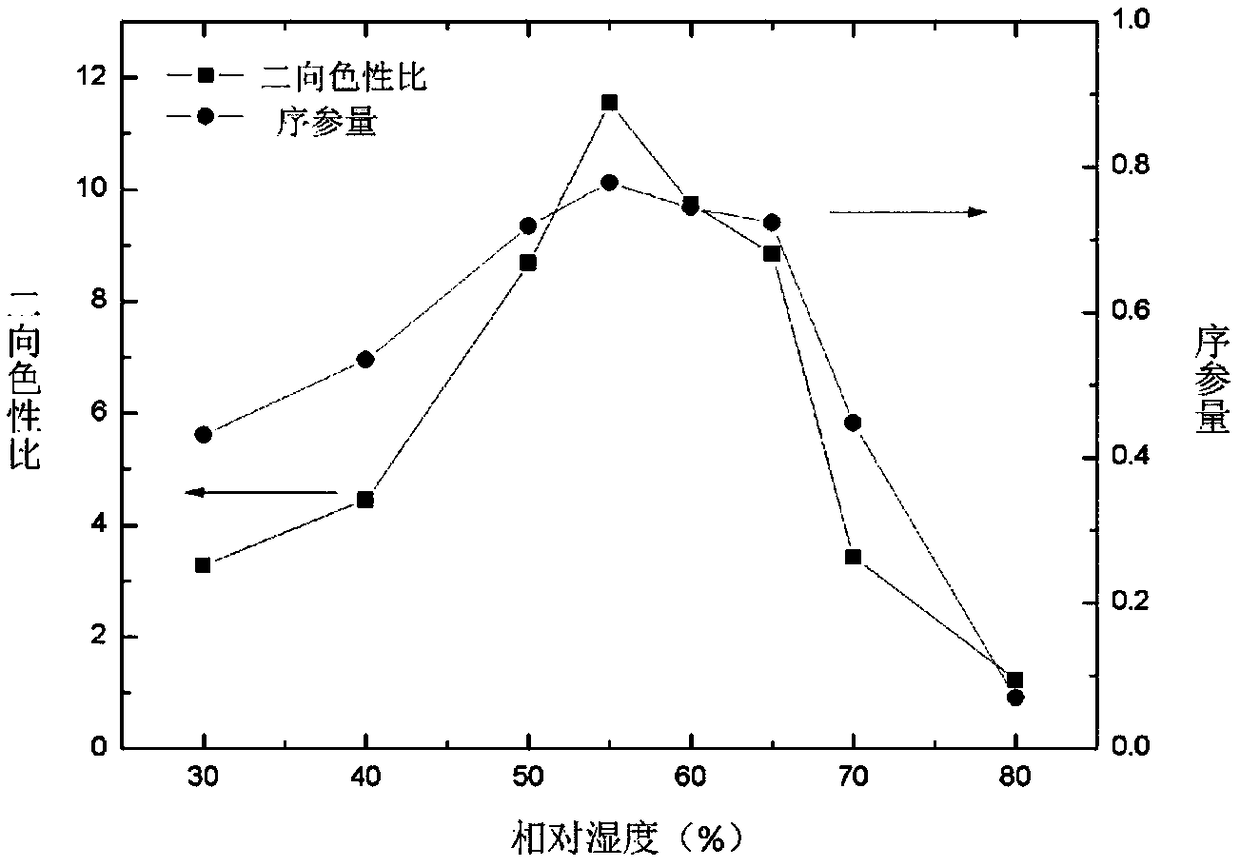

[0029] Under different relative humidity, use 5mW / cm 2 While irradiating with linearly polarized 365nm ultraviolet light, the phase retardation...

Embodiment 2

[0034] Embodiment 2 relative humidity is to the compound that the mixture of azo dye material, polymer monomer and photoinitiator forms The influence of the photoalignment quality of the object layer

[0035] Azo dye SD1, polymer monomer 4-(3-acryloyloxypropoxy)-benzoic acid 2-methyl-1,4-phenyl ester, photoinitiator 1-hydroxy-cyclohexyl-benzene The base-ketone was dissolved in dimethylformamide solvent. Wherein the azo dye and the polymer monomer are mixed in a weight ratio of 1:1, and the respective weight percentages of the azo dye and the polymer monomer relative to the solvent are 1%. The weight percentage of the photoinitiator relative to the monomer is 20%. Afterwards, the azo dye complex film was evenly covered on the substrate by spin coating, and the substrate was put into a closed compartment and directly removed from the glove box. Then the airtight cabin is connected with a humidity generator to obtain the required relative humidity inside and after equilibri...

Embodiment 3

[0040] Embodiment 3 relative humidity is to the compound that the mixture of azo dyestuff material, polymer monomer and thermal initiator forms The influence of the photoalignment quality of the object layer

[0041] Azo dye SD1, polymer monomer 4-(3-acryloyloxypropoxy)-benzoic acid 2-methyl-1,4-phenyl ester, thermal initiator 2-cyano-2-propane Dodecyl trithiocarbonate dissolved in dimethylformamide solvent. Wherein the azo dye and the polymer monomer are mixed in a weight ratio of 1:1, and the respective weight percentages of the azo dye and the polymer monomer relative to the solvent are 1%. The weight percent of the thermal initiator relative to the polymer monomer is 5%. Afterwards, the thermally polymerized azo dye complex film was uniformly covered on the substrate by spin coating, and the substrate was put into a closed compartment and directly removed from the glove box. Then the airtight cabin is connected with a humidity generator to obtain the required relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com