Biomass liquid fuel equivalent filtration and mixing device

A liquid fuel, mixing device technology, applied in mixers, filtration separation, mixing methods, etc., can solve the problems of low mixing efficiency, filter plugging, low efficiency, etc., and achieve the effect of improving and preventing plugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

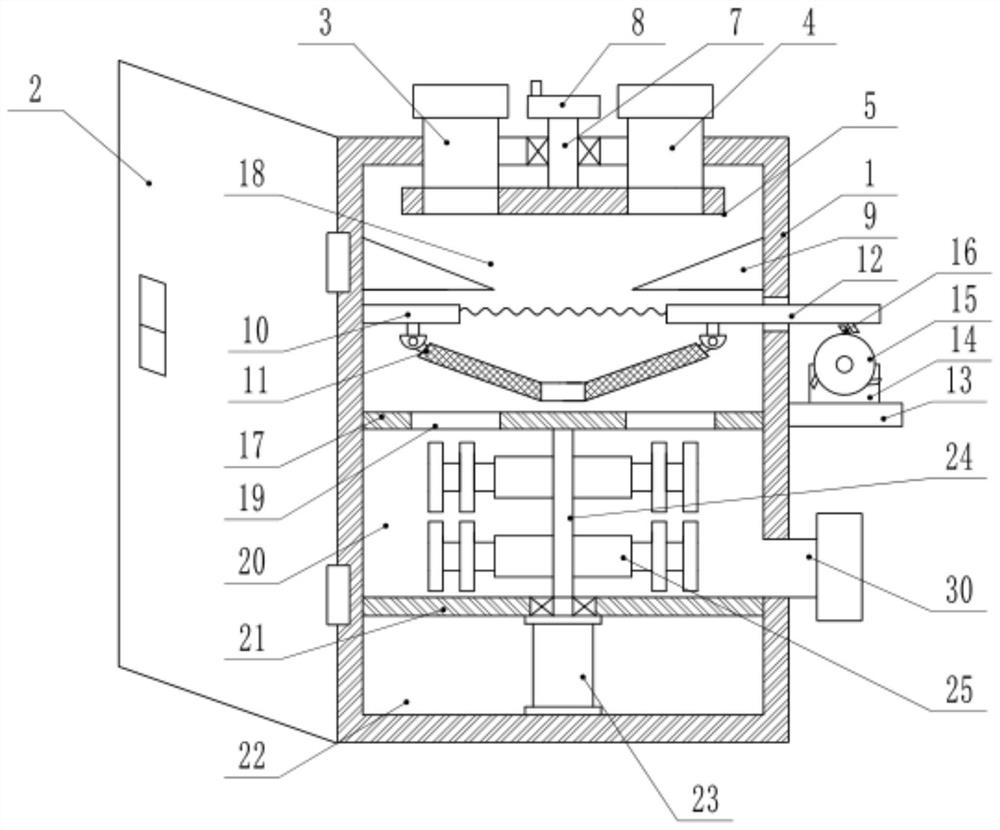

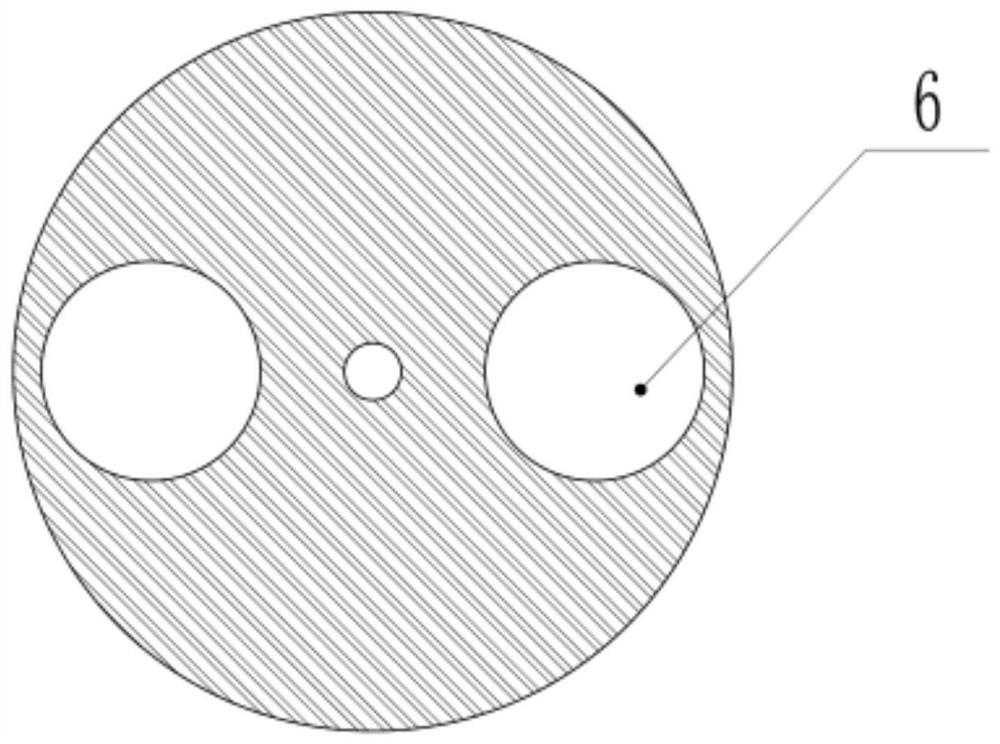

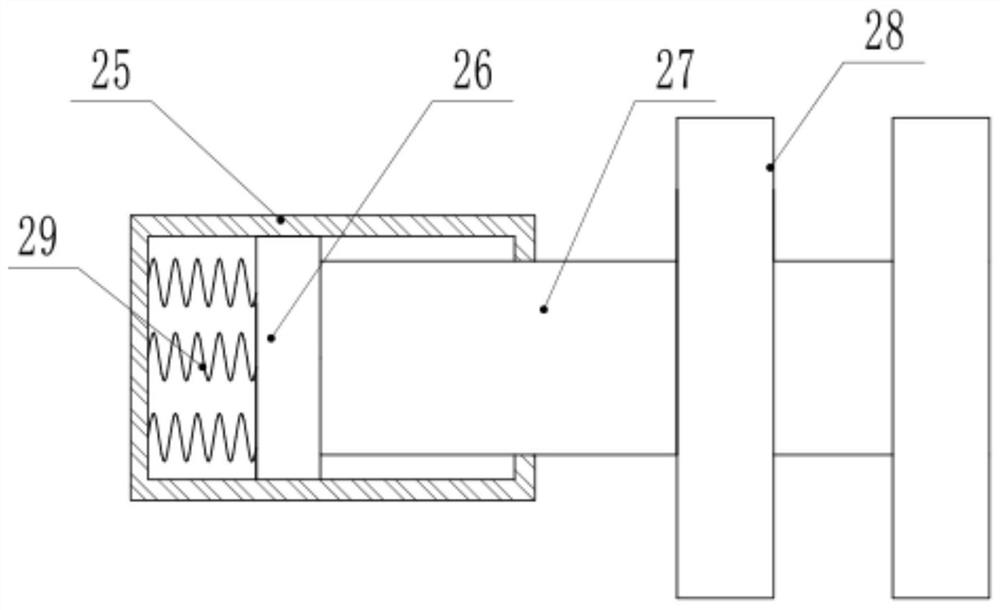

[0023]SeeFigure 1-3, A biomass liquid fuel equivalent filtering and mixing device, comprising a cabinet 1, an equal feed tray 5, a cabinet filter 11, a first drive motor 14, a second drive motor 23 and a stirring blade 28, the cabinet 1 left A tank door 2 is mounted on the side hinge. The left and right parts of the upper side of the chassis 1 are symmetrically embedded with a fuel feed pipe A3 and a fuel feed pipe B4. The outer ends of the fuel feed pipe A3 and the fuel feed pipe B4 are both aligned with The external fuel feeding device is connected, the lower ends of the fuel feeding pipe A3 and the fuel feeding pipe B4 extend into the inside of the chassis 1, and the lower ends of the fuel feeding pipe A3 and the fuel feeding pipe B4 are provided with an equal amount of feeding tray 5 , The equal-quantity feed tray 5 is in contact with the lower ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com