Monorail crawler-belt-type water cooling wall climbing detecting robot

A crawler-type, water-cooled wall technology, applied in the field of wall-climbing robots, can solve the problems of harsh working environment of boilers, hidden dangers to personal safety, low work efficiency, etc., to avoid hidden dangers to personal safety, reduce economic losses, and improve detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

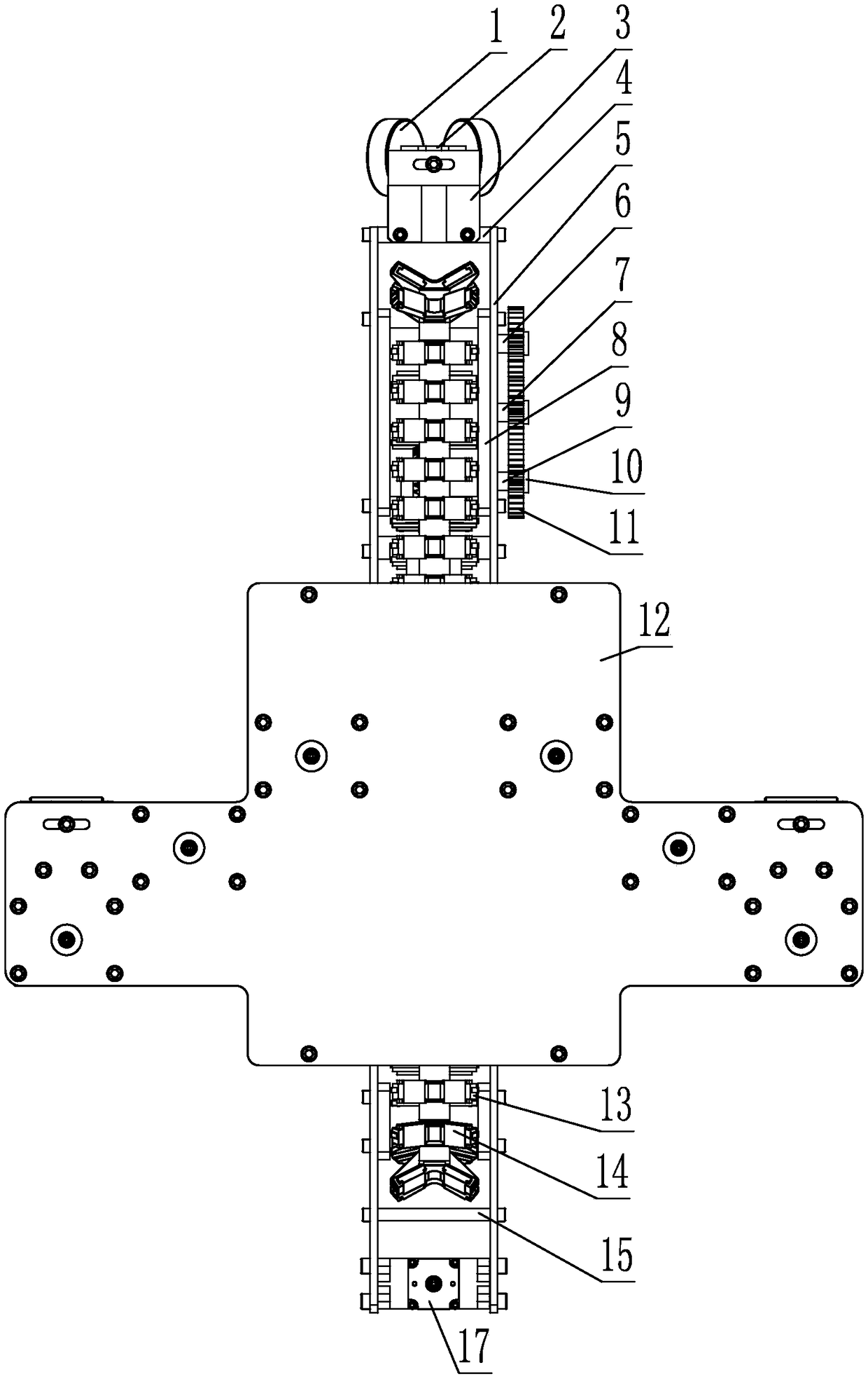

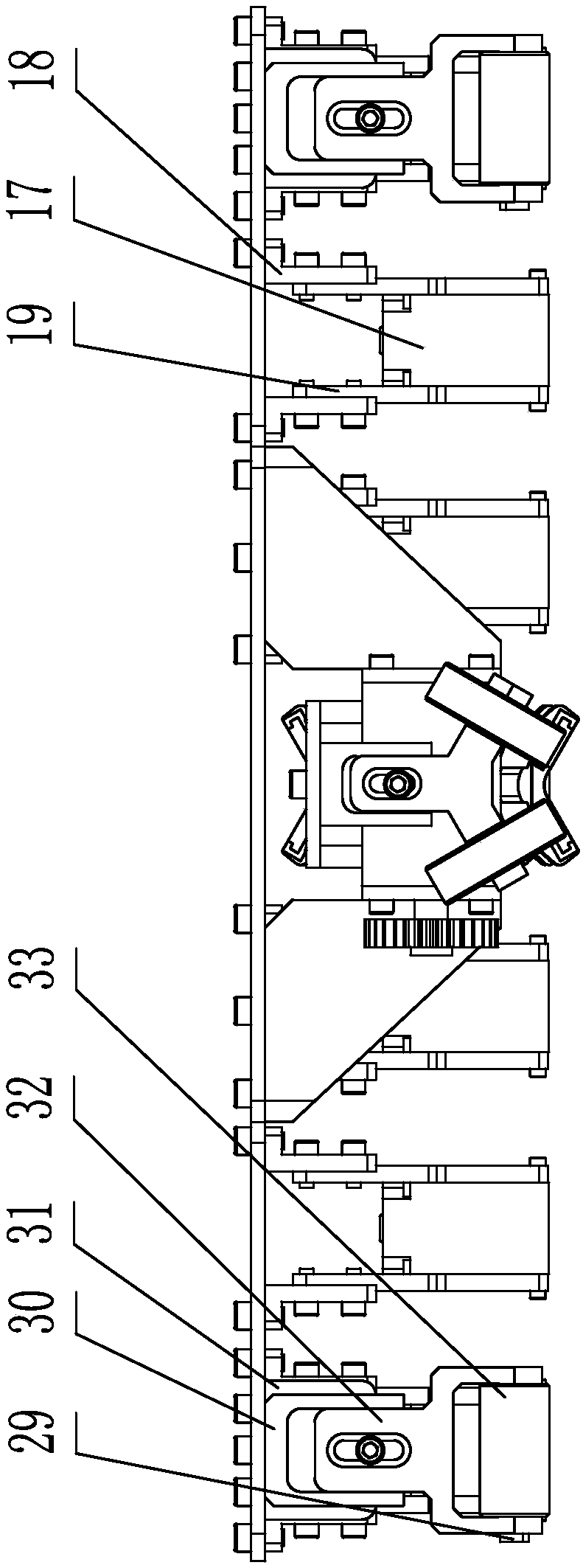

[0022] Specific implementation mode one: combine figure 1 with image 3 Describe this embodiment, a monorail crawler-type water-cooled wall wall-climbing detection robot of this embodiment, which includes a car body, a thickness measuring probe mechanism, an auxiliary support mechanism, a guide mechanism and a mounting plate 12, and the mounting plate 12 is fixed on the car body , the auxiliary support mechanism is arranged on both sides of the car body, the auxiliary support mechanism is fixedly connected with the mounting plate 12, the guide mechanism is installed at the front end of the car body, the car body and both sides of the car body are provided with a thickness measuring probe mechanism, and the car body both sides The thickness-measuring probe mechanism is fixed on the mounting plate 12, and the thickness-measuring probe mechanism on the car body is fixed on the lower end of the car body.

[0023] The auxiliary supporting mechanism is arranged on both sides of the...

specific Embodiment approach 2

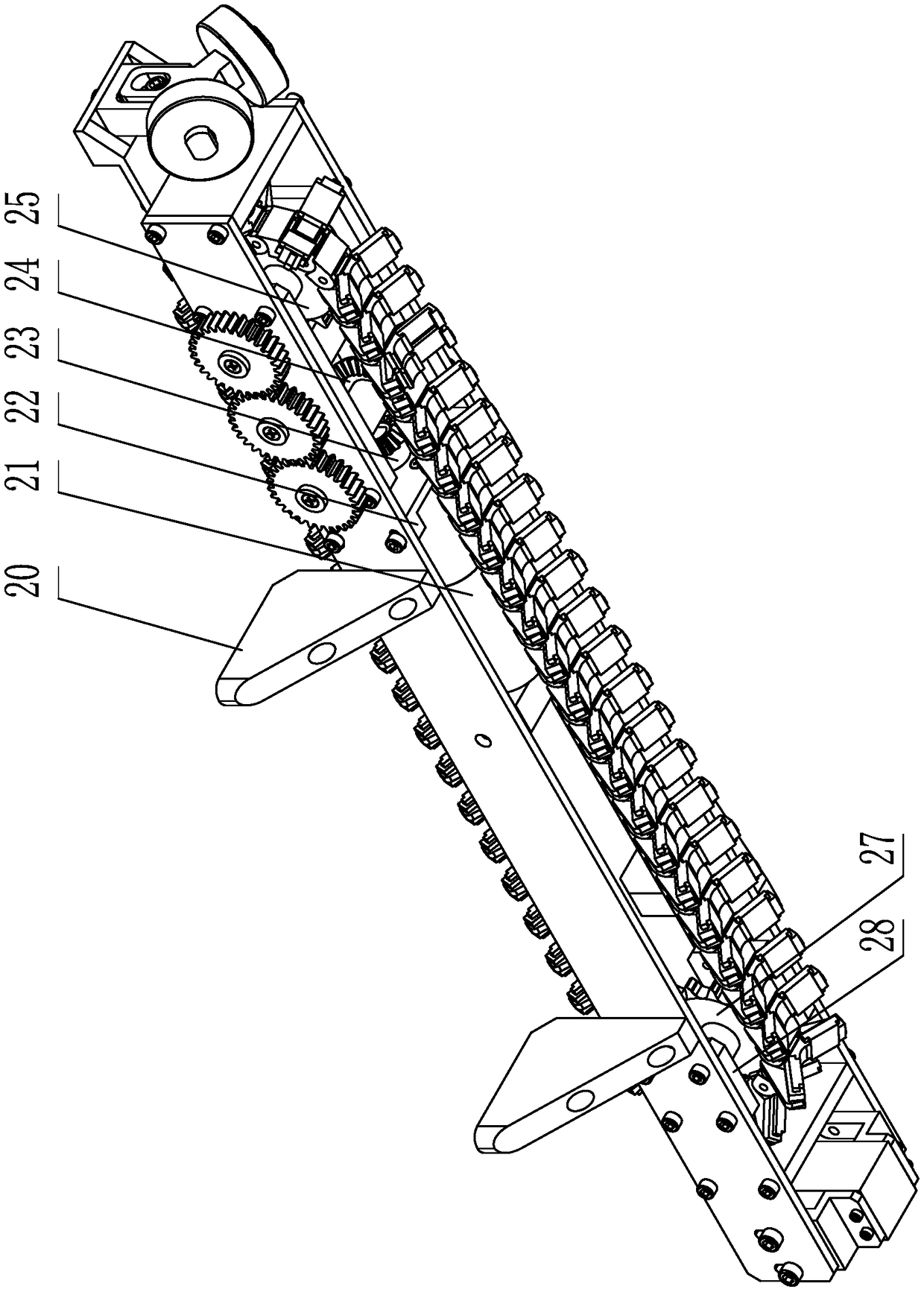

[0024] Specific implementation mode two: combination figure 1 with figure 2 Describe this embodiment, the vehicle body of this embodiment comprises guide mounting plate 4, crawler belt connecting plate 5, driving wheel shaft 6, second transmission shaft 7, first bearing seat 8, first transmission shaft 9, crawler belt 13, upper mounting plate 15. Motor 21, motor mounting plate 22, first bevel gear 23, second bevel gear 24, track driving wheel 25, track driven wheel 27, second bearing seat 28, three gear blocks 10, three driving gears 11 , four ribs 20 and a plurality of magnets 14, four ribs 20 are symmetrically installed on both sides of the track connecting plate 5, the car body is connected with the mounting plate 12 by four ribs 20, the track driving wheel 25 and the track driven wheel 27 is installed at both ends of the track 13, a plurality of magnets 14 are evenly distributed on the track 13, the first bearing seat 8 is installed inside the front end of the track conn...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 with figure 2 Describe this embodiment, the guide mechanism of this embodiment comprises guide wheel frame 2, guide wheel vertical adjustment seat 3 and two guide wheels 1, two guide wheels 1 are installed on the guide wheel frame 2, guide wheel frame 2 and installation The guide mounting plate 4 at the front end of the track connecting plate 5 is affixed. With such arrangement, the structure of the guiding mechanism is simple and the guiding effect is good. The two guiding wheels 1 are all magnetic wheels, which can provide magnetic force for the vehicle body to walk along the water-cooled wall. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com