A kind of fiber antioxidant and preparation method thereof

An antioxidant and fiber technology, applied in the direction of fiber treatment, fiber type, light-resistant fiber, etc., can solve the problems of low number of anti-oxidation and anti-yellowing effects at high temperature, high cost, good anti-oxidation effect, and no heavy metal ions. , excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A fiber antioxidant, which comprises the following components by weight:

[0033]

[0034] A preparation method of the above fiber antioxidant, which comprises the following steps:

[0035] (1) Add 10 parts of AEO7 and 20 parts of AES to the reactor, and stir at 100rpm / min for 30min;

[0036] (2) Add 5 parts of benzyl hydroxylamine and 20 parts of ethanol, heat to 43°C, stir and react for 3 hours, and add 22.5 parts of water when the material is a transparent liquid;

[0037] (3) Cool down to 28°C, add the remaining water, and stir to obtain the finished product.

Embodiment 2

[0039] A fiber antioxidant, which comprises the following components by weight:

[0040]

[0041] A preparation method of the above fiber antioxidant, which comprises the following steps:

[0042] (1) Add 10 parts of EL-406 parts and 10 parts of MES to the reaction kettle, and stir at 100rpm / min for 30min;

[0043] (2) Add 10 parts of benzyl hydroxylamine and 30 parts of isopropanol, heat to 43°C, stir and react for 3 hours, and add 22 parts of water when the material is a transparent liquid;

[0044] (3) Cool down to 28°C, add the remaining water, and stir to obtain the finished product.

Embodiment 3

[0046] A fiber antioxidant, which comprises the following components by weight:

[0047]

[0048] A preparation method of the above fiber antioxidant, which comprises the following steps:

[0049] (1) Add 402 parts of castor oil polyoxyethylene ether and 5 parts of dodecyl benzene sulfonic acid into the reaction kettle, and stir for 30 minutes at 100 rpm / min;

[0050] (2) Add 15 parts of benzyl hydroxylamine and 50 parts of stearyl alcohol, heat to 43°C, stir and react for 3 hours, and add 5 parts of water when the material is a transparent liquid;

[0051] (3) Cool down to 28°C, add the remaining water, and stir to obtain the finished product.

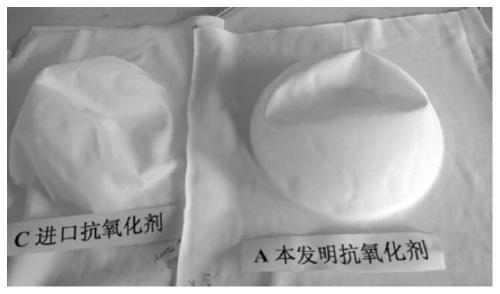

[0052] The present invention is mainly aimed at the anti-oxidation yellowing protection effect of white fiber fabric after high temperature 180 to 220°C treatment. The white fabric treated with the product prepared in the embodiment of the present invention does not have obvious yellowing after high temperature treatment. The white fiber fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com